LT CNCMN-200A CNC Busbar Chamfering Machine processes copper & aluminum busbars with thickness 4-16mm, width 30-200mm. Features 6000rpm spindle, 5-axis CNC control, automatic 6-station tool changer, and BT40 tool holders. Professional arc milling and edge processing solution.

CNCMN-200A CNC BUSBAR CHAMFERING MACHINE

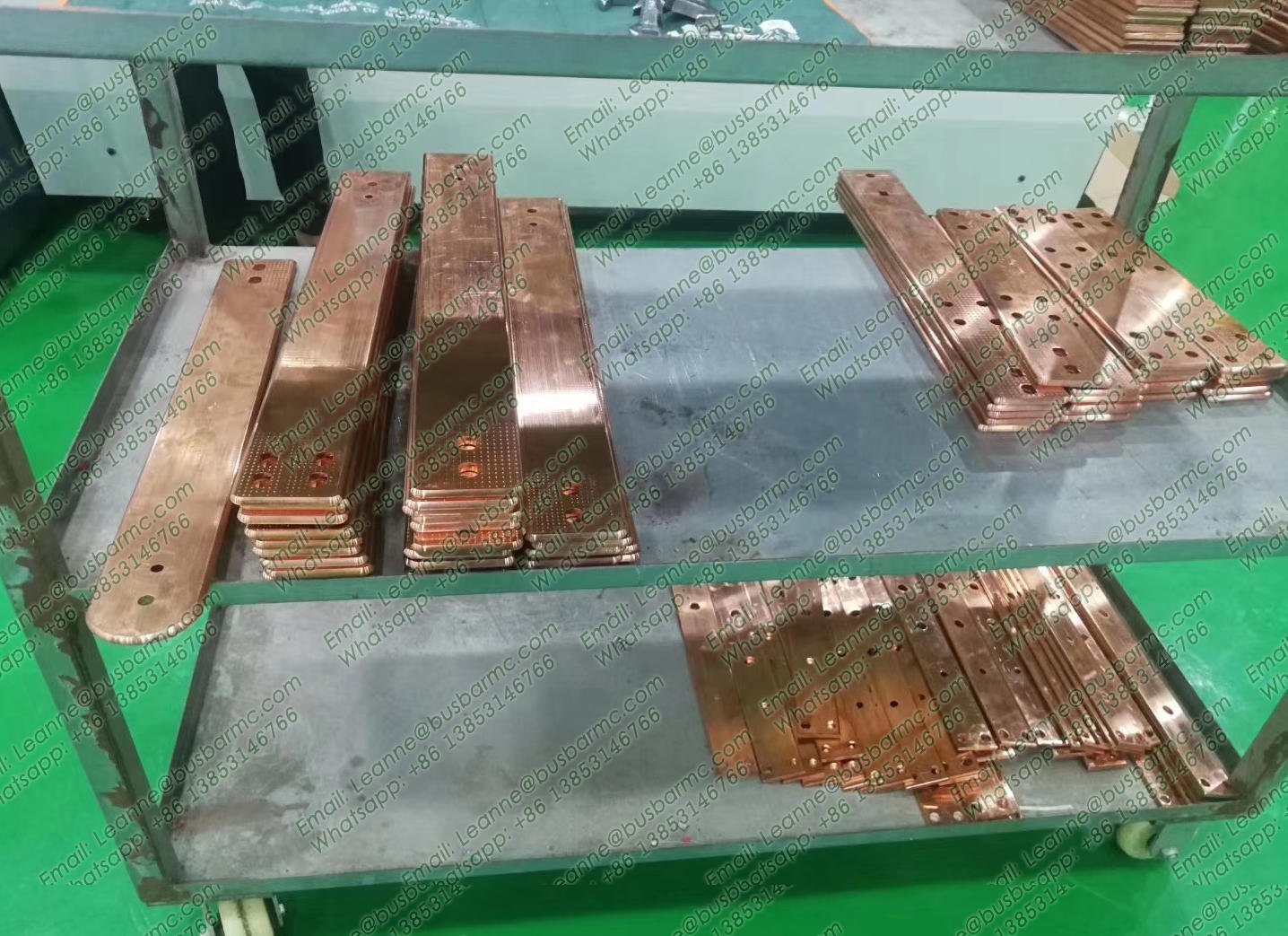

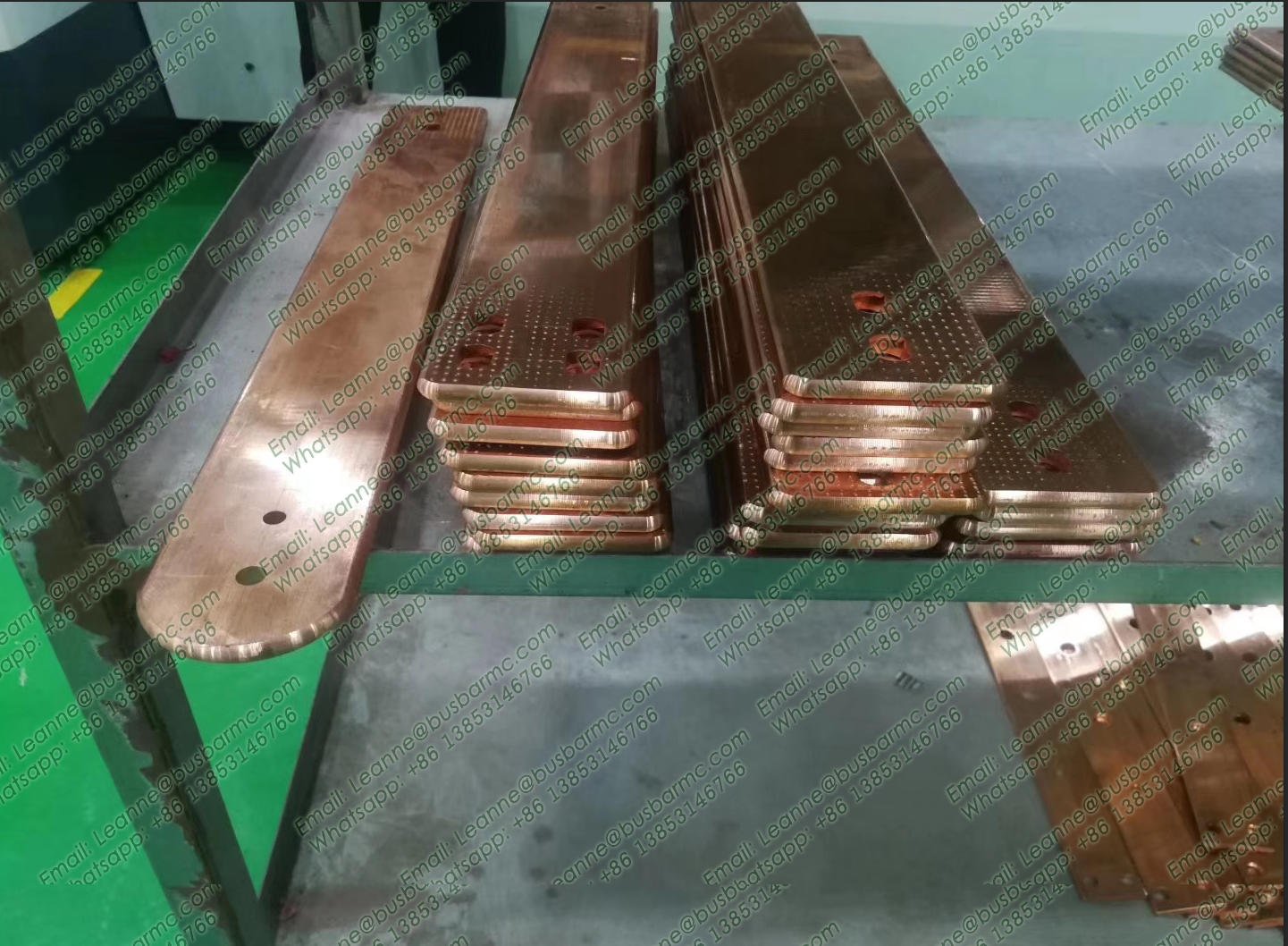

The main function of the busbar arc processing center is to perform chamfering (arc) processing on the ends of copper and aluminum busbars with thickness 4-16mm and width 30-200mm.

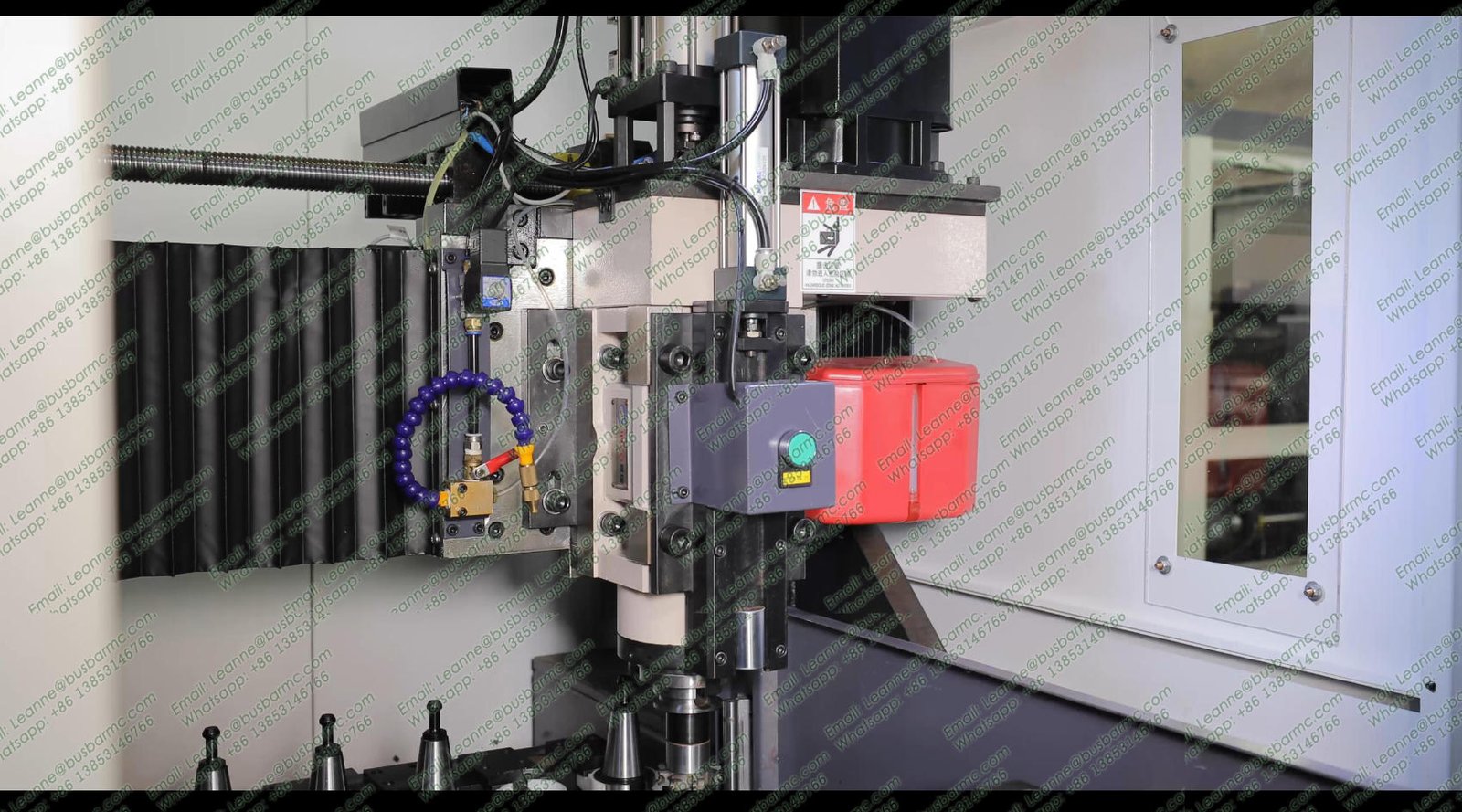

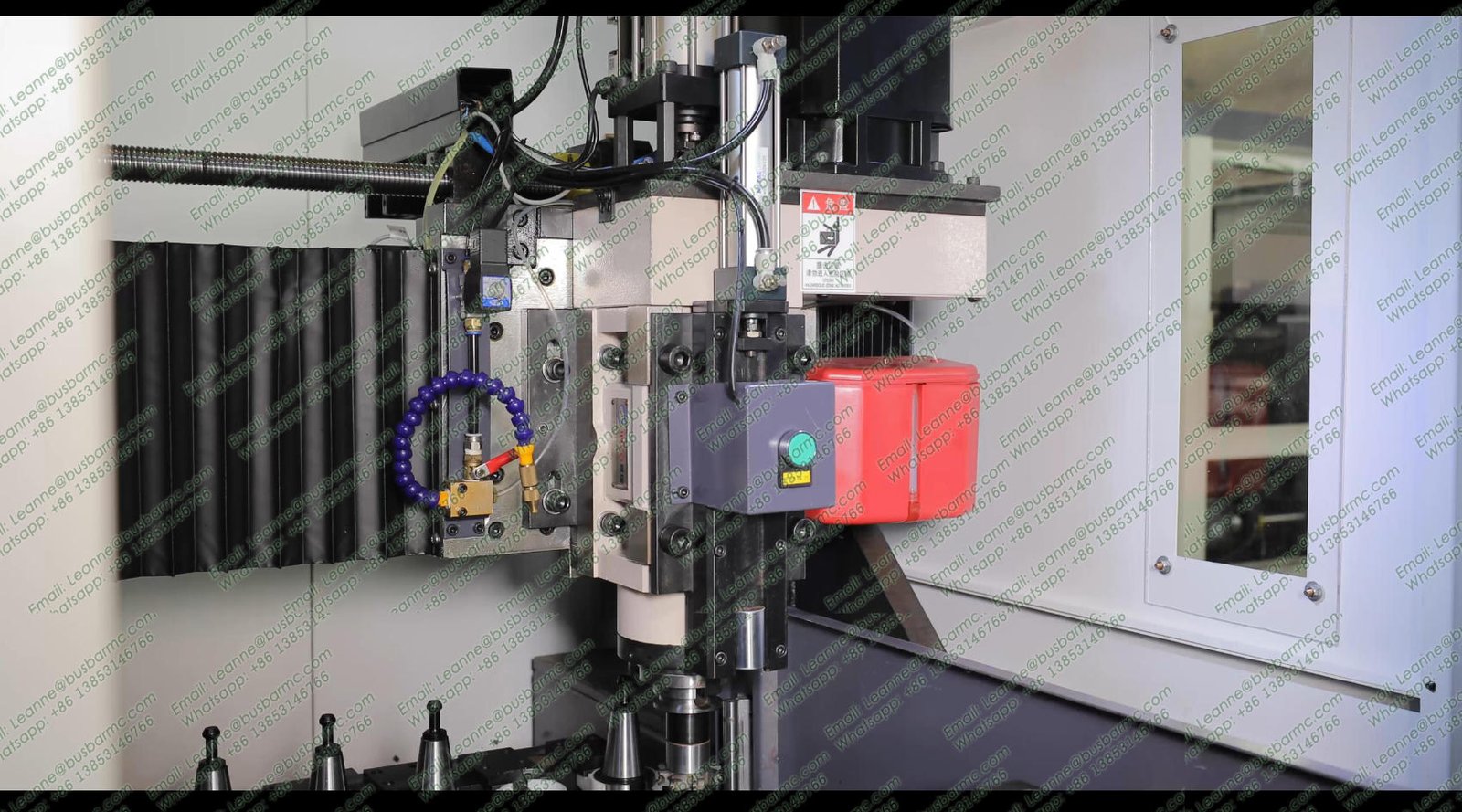

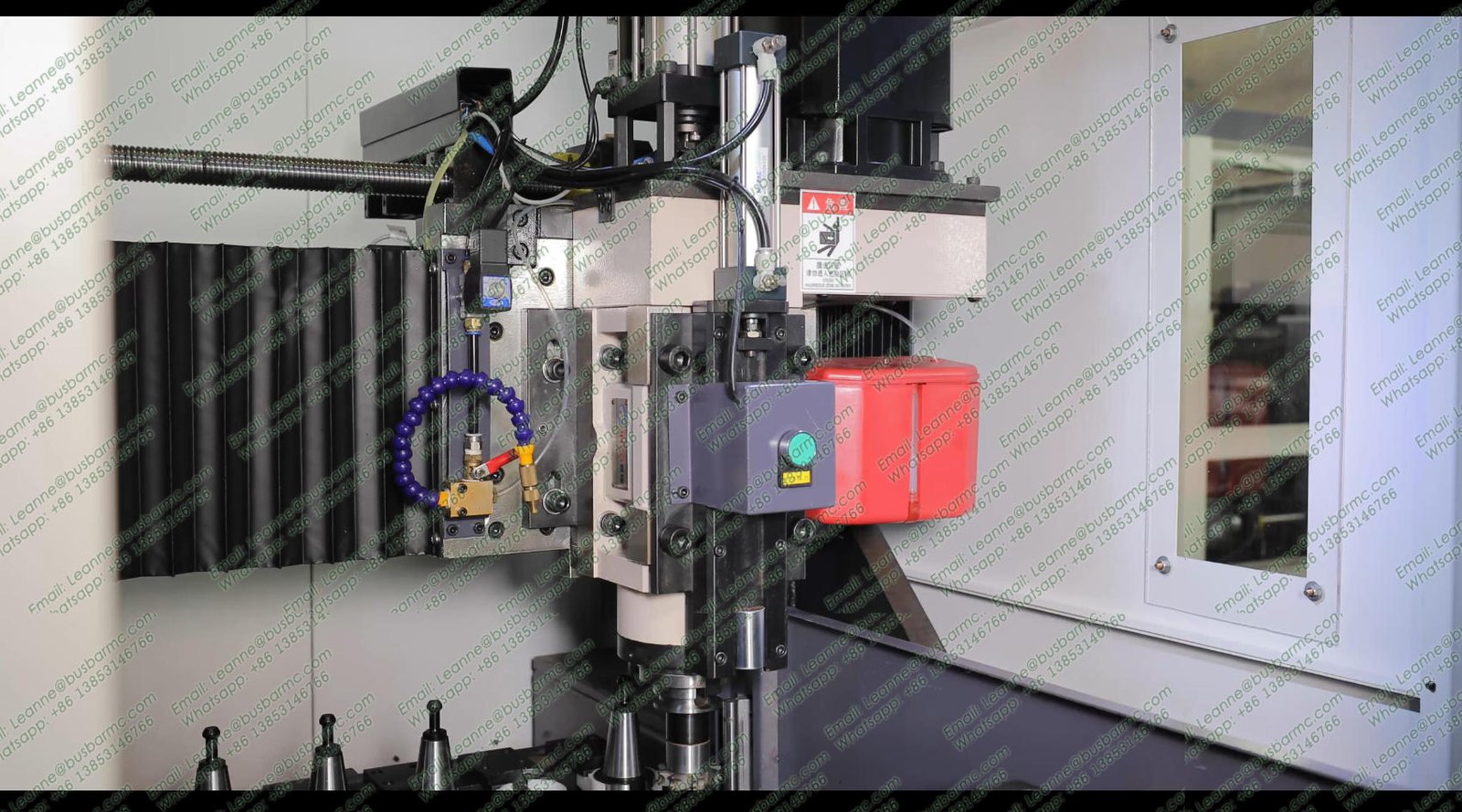

▲ Gantry mechanical structure, simple design, stable operation, good structural rigidity

▲ Six-station inline tool magazine, automatic tool change with BT40 tool holders

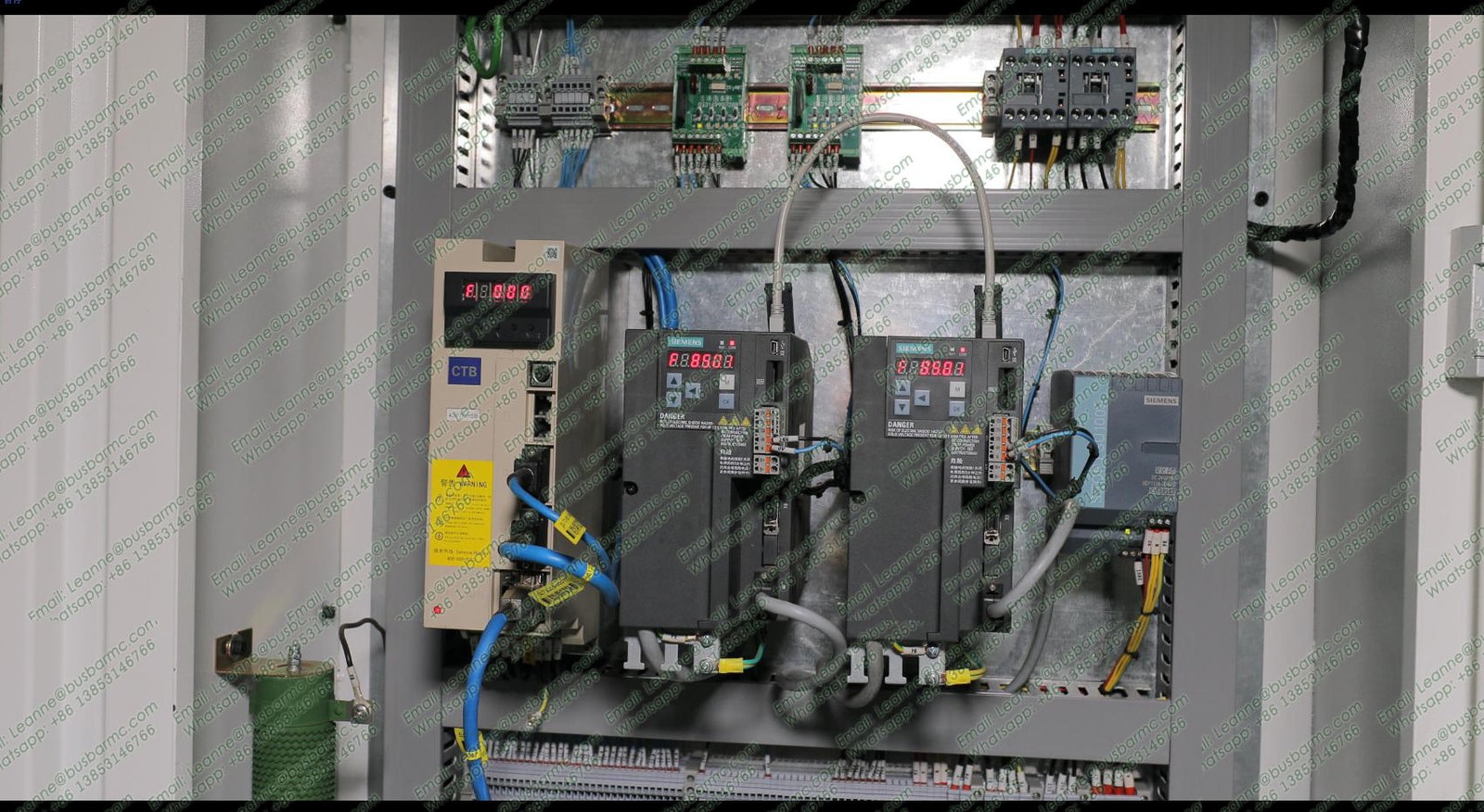

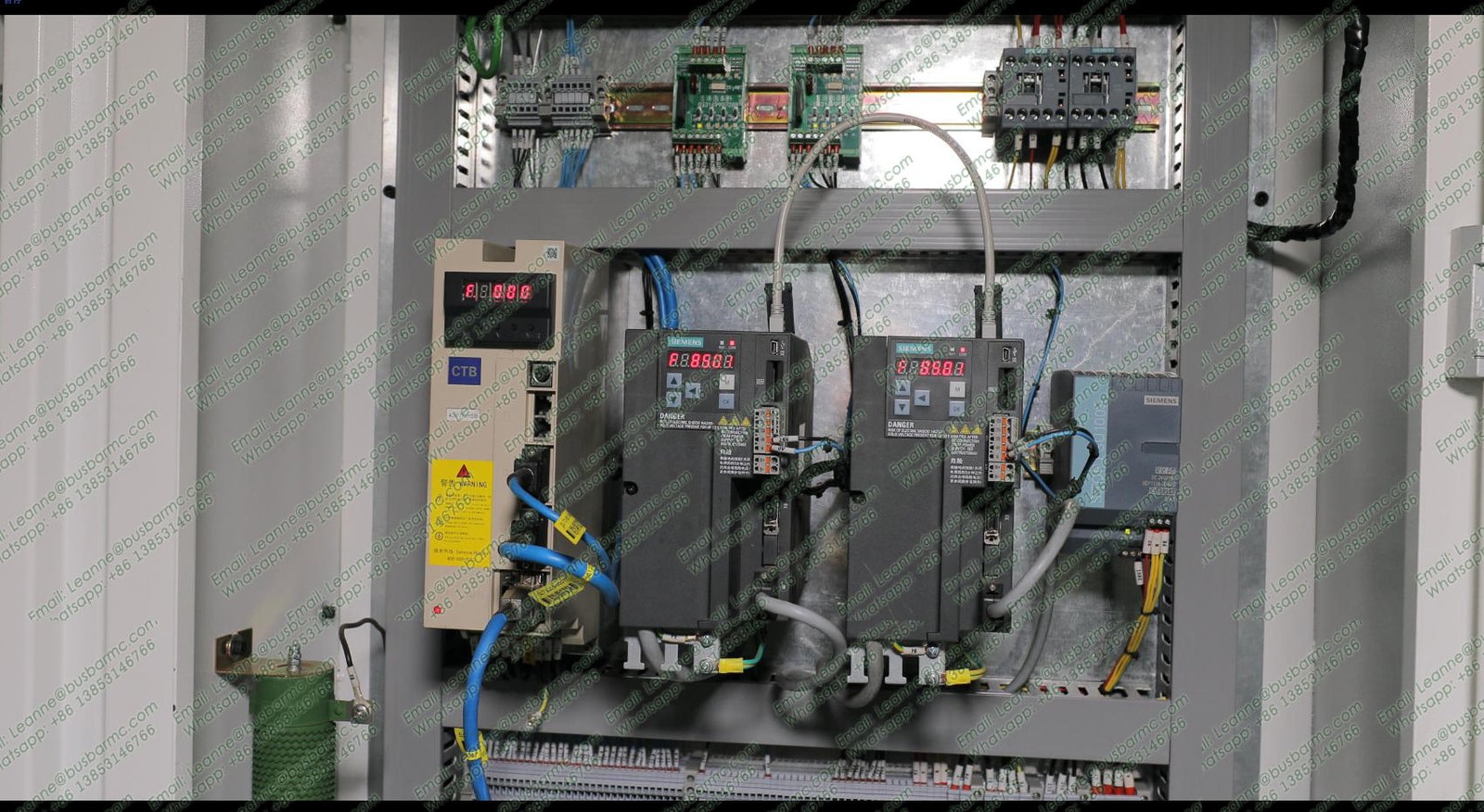

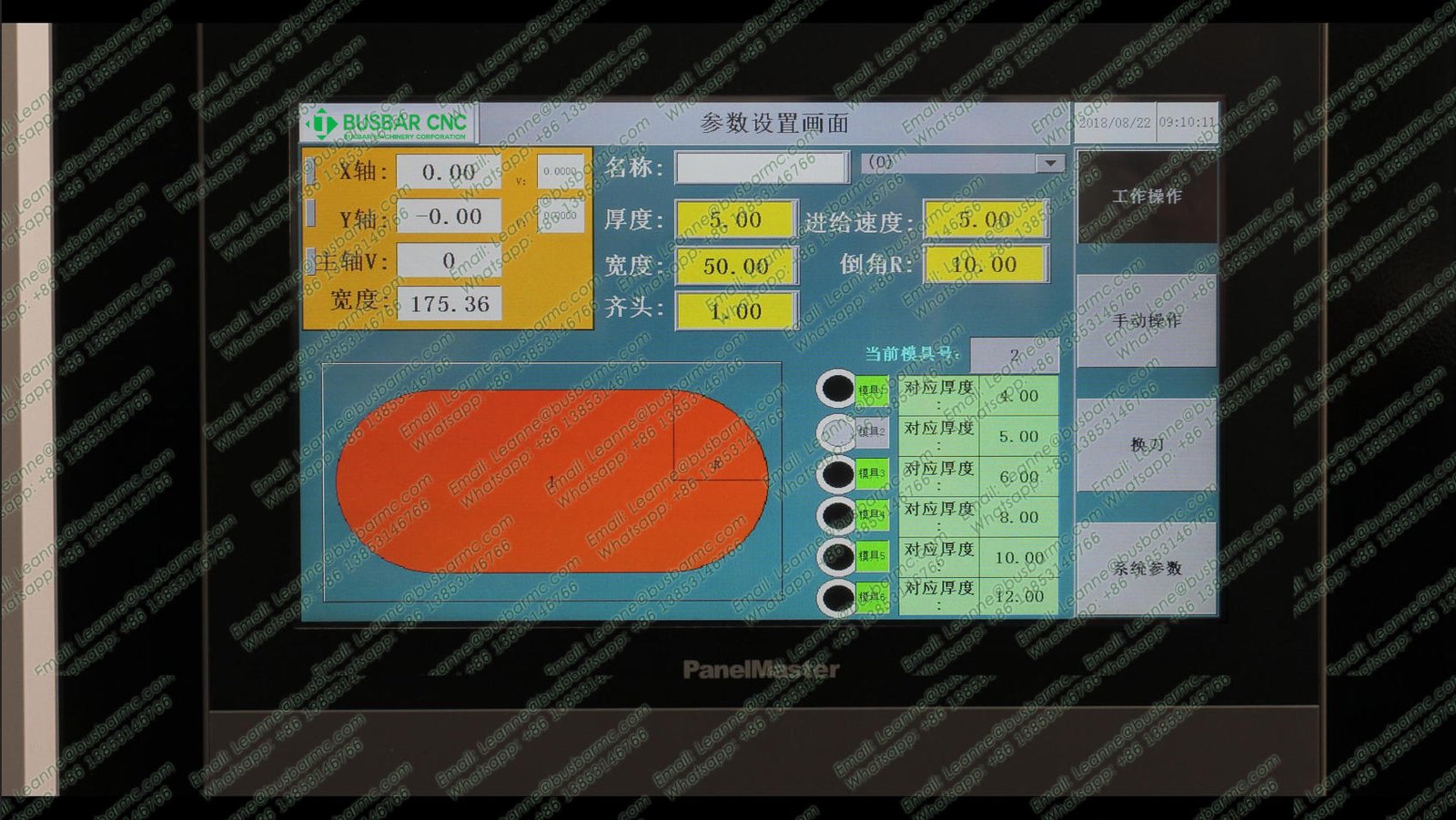

▲ 5-axis CNC control system with 10.4″ LCD display

▲ Maximum spindle speed: 6000 r/min, main motor power: 3.7 KW

▲ Processes busbars: length 150-6000mm, width 30-200mm, thickness 4-16mm

| No. | Technical Parameters | Unit | Value | No. | Technical Parameters | Unit | Value |

| 1 | Maximum spindle speed | r/min | 6000 | 2 | Main motor power | KW | 3.7 |

| 3 | Maximum X-axis travel | mm | 525 | 4 | Maximum speed of X axis | m/min | 15 |

| 5 | X-axis positioning accuracy | mm | ±0.08 | 6 | Maximum travel of X axis | mm | 500 |

| 7 | Maximum Y-axis speed | m/min | 15 | 8 | Positioning accuracy of Y axis | mm | ±0.08 |

| 9 | Maximum Z-axis travel | mm | 130 | 10 | Positioning accuracy of Z axis | mm | ±0.05 |

| 11 | Workpiece length that can be processed | mm | 150-6000 | 12 | Machinable workpiece width | mm | 30-200 |

| 13 | Machinable workpiece thickness | mm | 4-16 | 14 | Dimensions | mm | 2260×1580×2100 |

| No. | Technical Parameters | Unit | Value | No. | Technical Parameters | Unit | Value |

| 1 | Number of CNC axes | PC | 5 | 2 | X-axis servo motor power | KW | 2 |

| 3 | Y-axis servo motor power | KW | 2 | 4 | Z-axis servo motor power | KW | 1 |

| 5 | Air source pressure | MPa | 0.6-0.8 | 6 | Hydraulic pump motor power | KW | 2 |

| 7 | Total power | KW | 12 | ||||

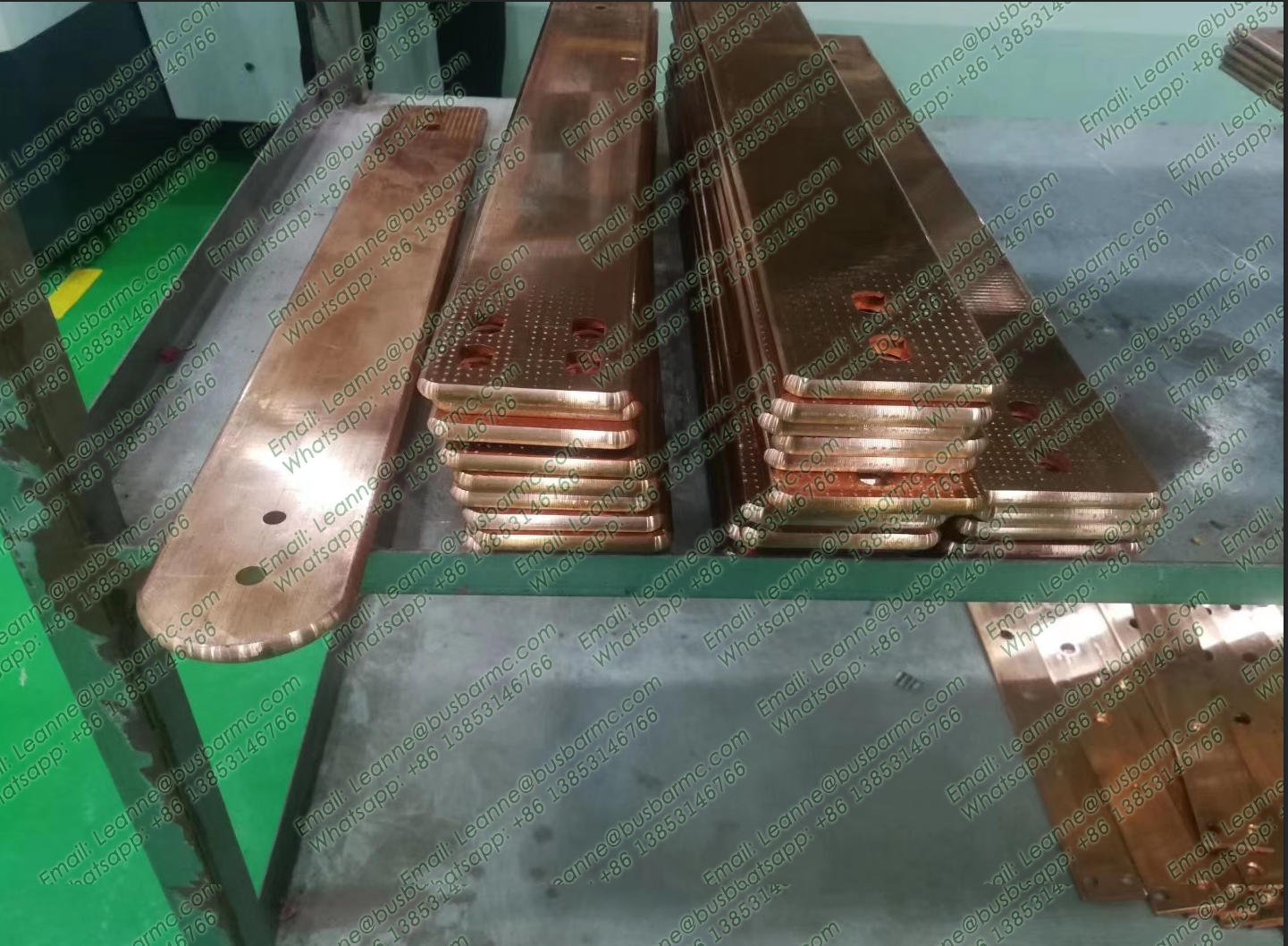

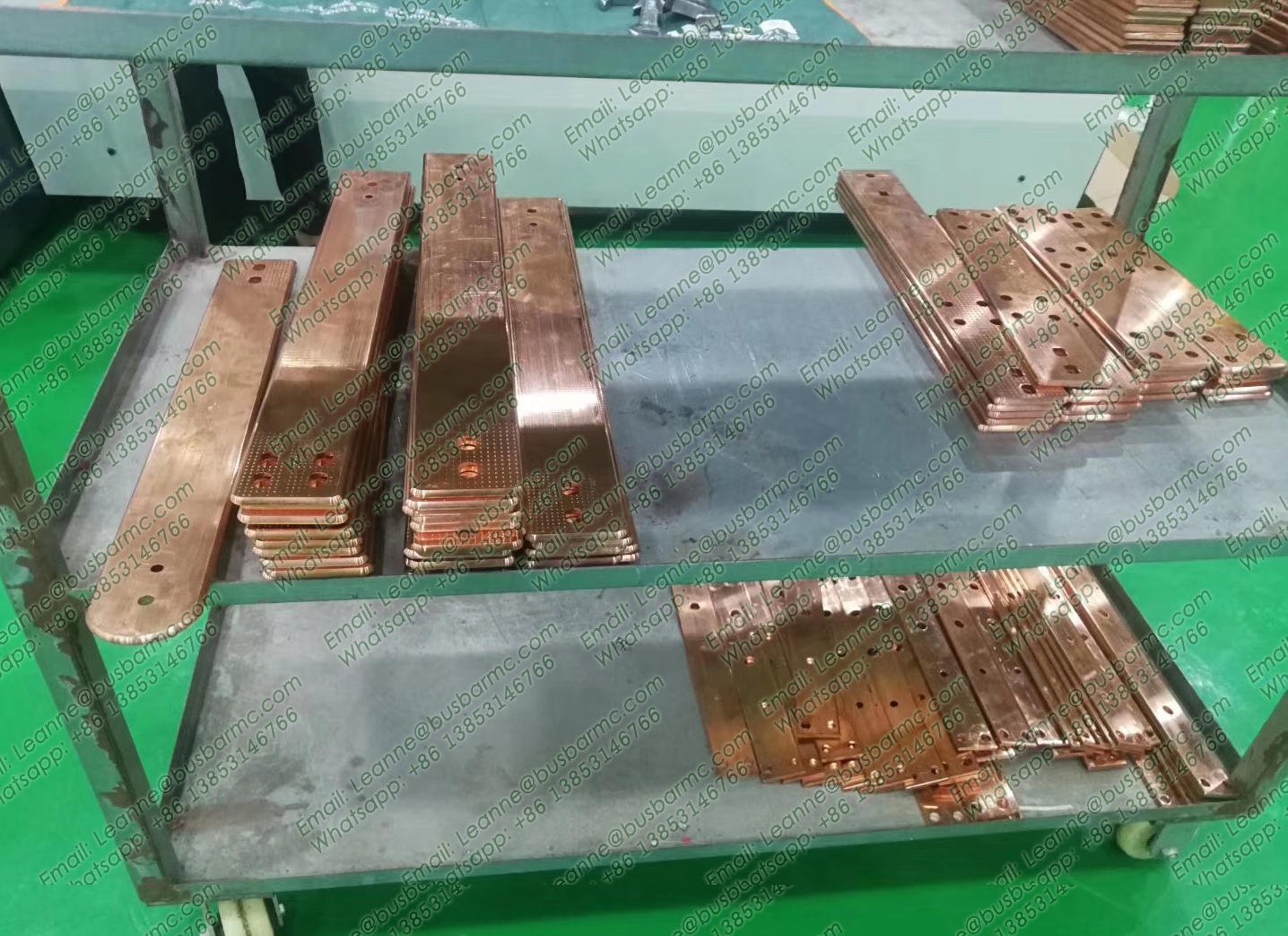

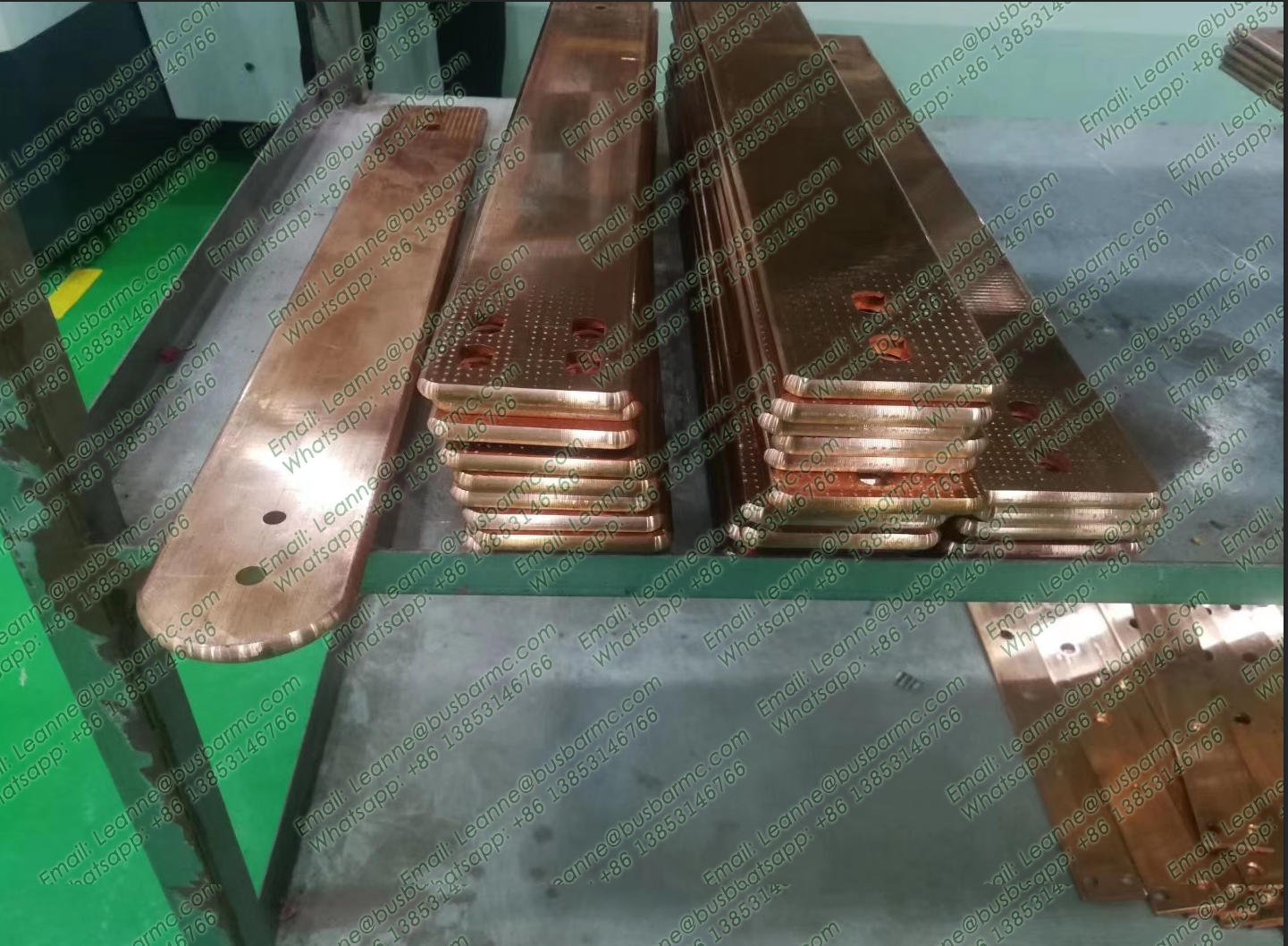

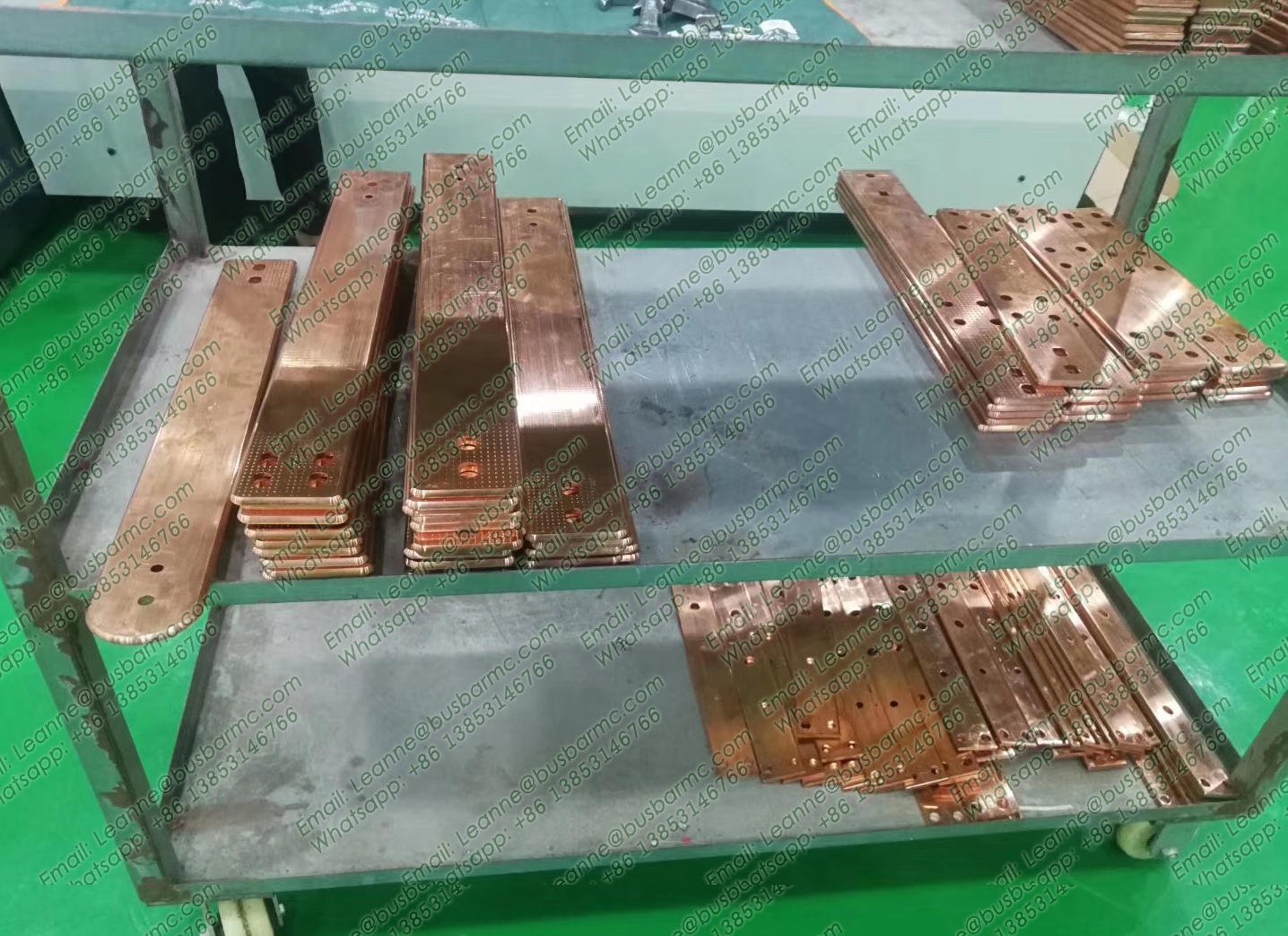

Product Images

CNC Busbar Chamfering Machine

CNC Busbar Arc Milling Machine

Copper Busbar Edge Chamfering Machine

Copper Aluminum Busbar Processing Machine

CNC Copper Bar Chamfer Cutting Machine

Busbar Chamfering Machine

Busbar Chamfering Machine

Busbar Chamfering Machine

| No. | Item | Quantity | Description |

| 1. | Milling cutter | 6 sets | 4mm, 5mm, 6mm, 8mm, 10mm, 12mm |

| 2. | Tool holder device | 1 set | |

| 3. | Screwdrivers | 2 sets | 2 bigger screwdrivers, 2 small screwdrivers |

| 4. | Inductive proximity sensor | 1 pc | |

| 5. | Double-head wrench | 1 set | |

| 6. | Oil sprayer | 1 pc | |

| 7. | Oil lubrication box | 1 pc | |

| 8. | Bending shaft hole cover | 6 pcs | |

| 9. | Oil hose | 1 pc |

Video Demonstration

Frequently Asked Questions

Q1: What is the main function of the CNCMN-200A CNC busbar chamfering machine?

The main function is to perform chamfering, arc milling, and edge processing on copper and aluminum busbar ends with thickness 4-16mm and width 30-200mm.

Q2: What type of structure does this machine use?

The machine uses a gantry mechanical structure with a fully welded steel plate box design, providing high rigidity and stable operation.

Q3: How many tools can the machine hold?

It is equipped with a six-station inline tool magazine that supports automatic tool change using BT40 tool holders.

Q4: What CNC control system does the machine use?

The machine adopts a 5-axis CNC control system with a 10.4″ LCD display, capable of program storage, workload counting, and simulation.

Q5: What is the maximum processing size of the busbar?

The machine can process busbars with length 150-6000mm, width 30-200mm, and thickness 4-16mm.

Product Tags

CNC busbar chamfering machine, CNC busbar arc milling machine, copper busbar edge chamfering machine, aluminum busbar arc cutting machine, copper aluminum busbar processing machine, CNC busbar forming machine, busbar arc shaping equipment, busbar end-face milling machine, CNC copper bar chamfer cutting machine, automatic busbar edge rounding machine