The CNCMN-200A CNC busbar chamfering machine delivers precise arc, angle and edge milling for copper and aluminum busbars. Features a gantry structure, BT40 spindle, 6-tool automatic changer, 5-axis CNC control, and high-speed stable cutting for 4–16mm busbars up to 6000mm.

Product :

CNC Busbar Milling Machine / CNC Double-Head Busbar Milling Machine CNCDMN-200A

Serial:CNCDMN-200A

Main Function:

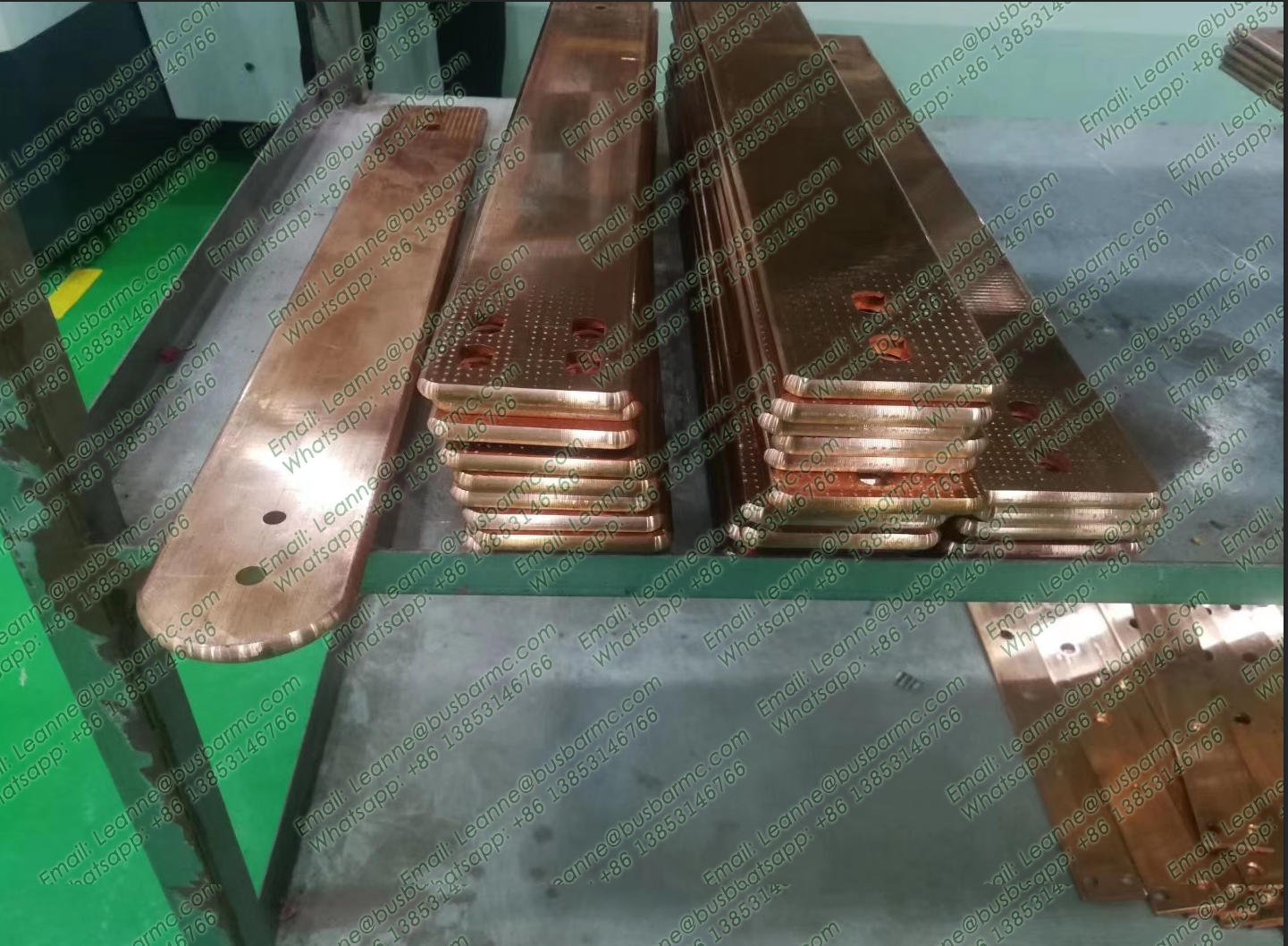

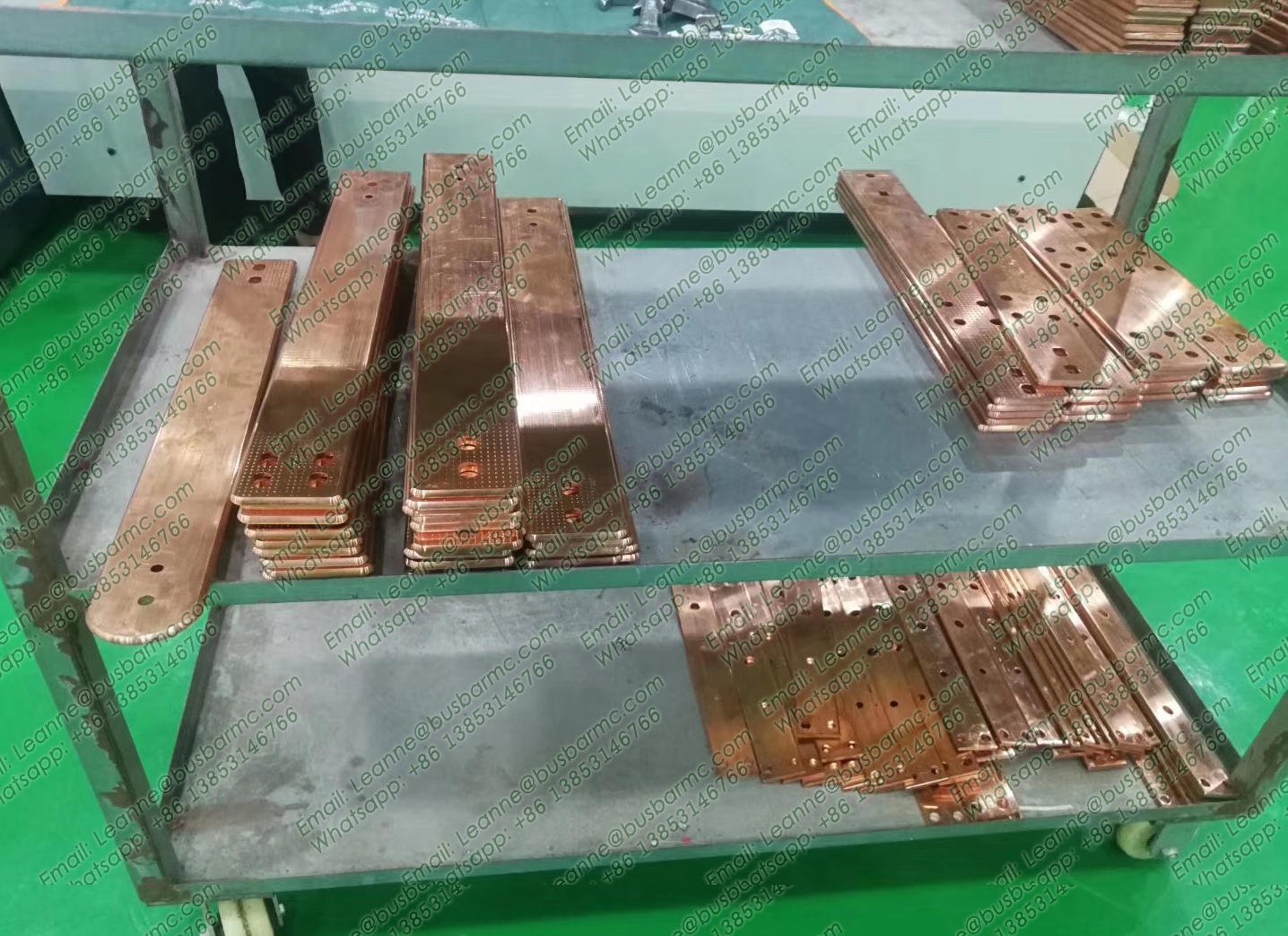

This machine is a high-efficiency, automated busbar corner milling machine controlled by a computer (11-axis CNC),

specifically designed for fully CNC-controlled comer milling of copper and aluminum busbars.

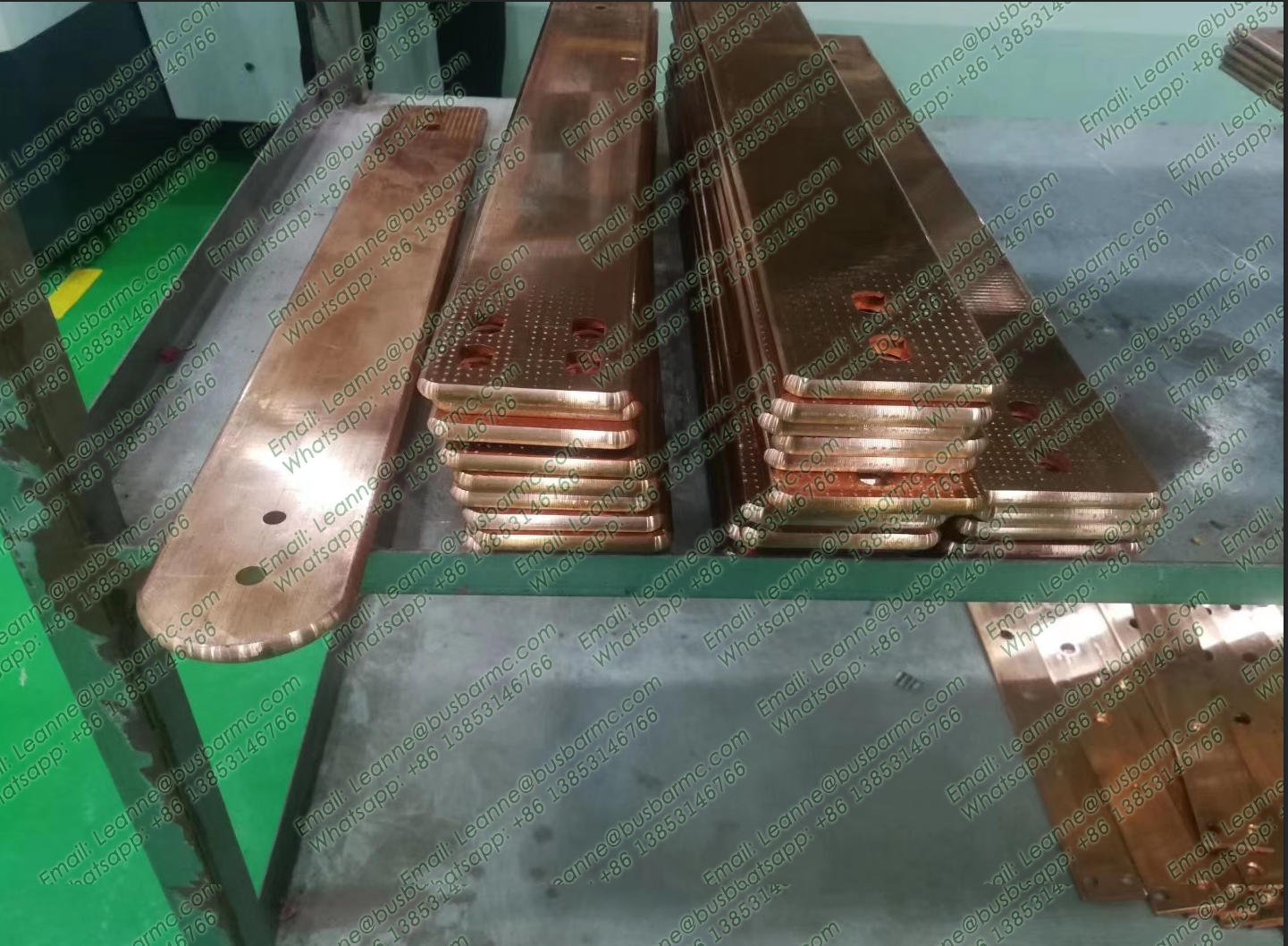

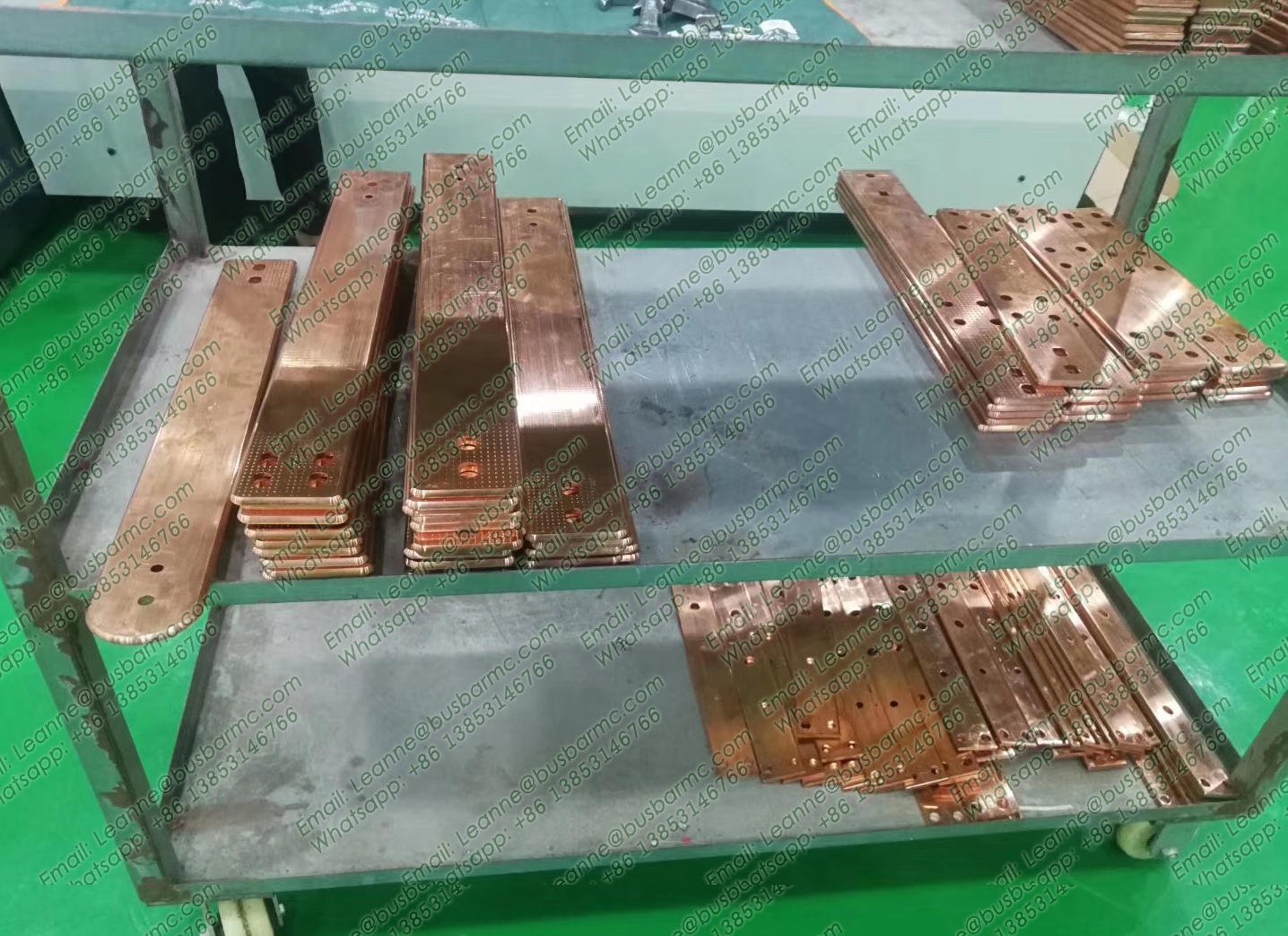

The main function of the machine is to perform arc machining on the end of copper busbar. It is mainly used for milling angle and arc angle of copper and aluminum busbars with thickness of 4-16mm and width of 30-200mm. It has simple structure with convenient use.

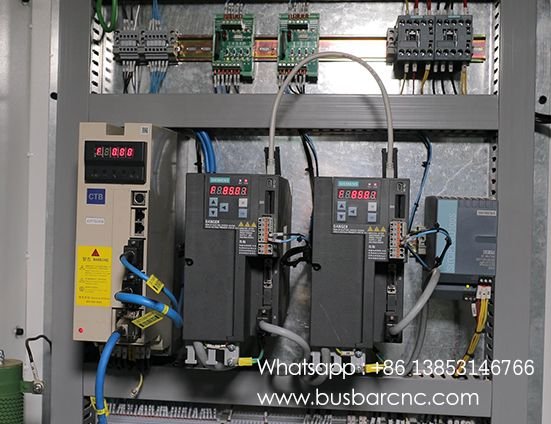

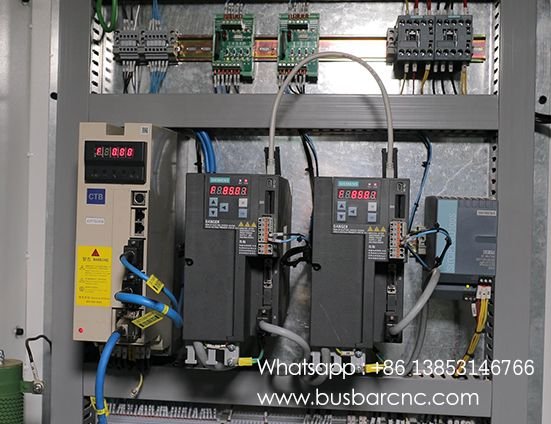

Control mode:

The electrical control is controlled by a 5-axis CNC system. The feeding and cutting of copper busbar are completed through the start-up of the spindle motor and servo motor. The clamping or loosening of the cutter is completed by pneumatic control.

The two-axis CNC automatic control system is adopted, and a 10.4"LCD is equipped, which can display the working state of the machine tool. It has the functions of storing according to the input work number, calling the counting of workload, displaying and communicating, simulating processing, as well as online manual programming.

Machine tool structure, advantages and operation characteristics:

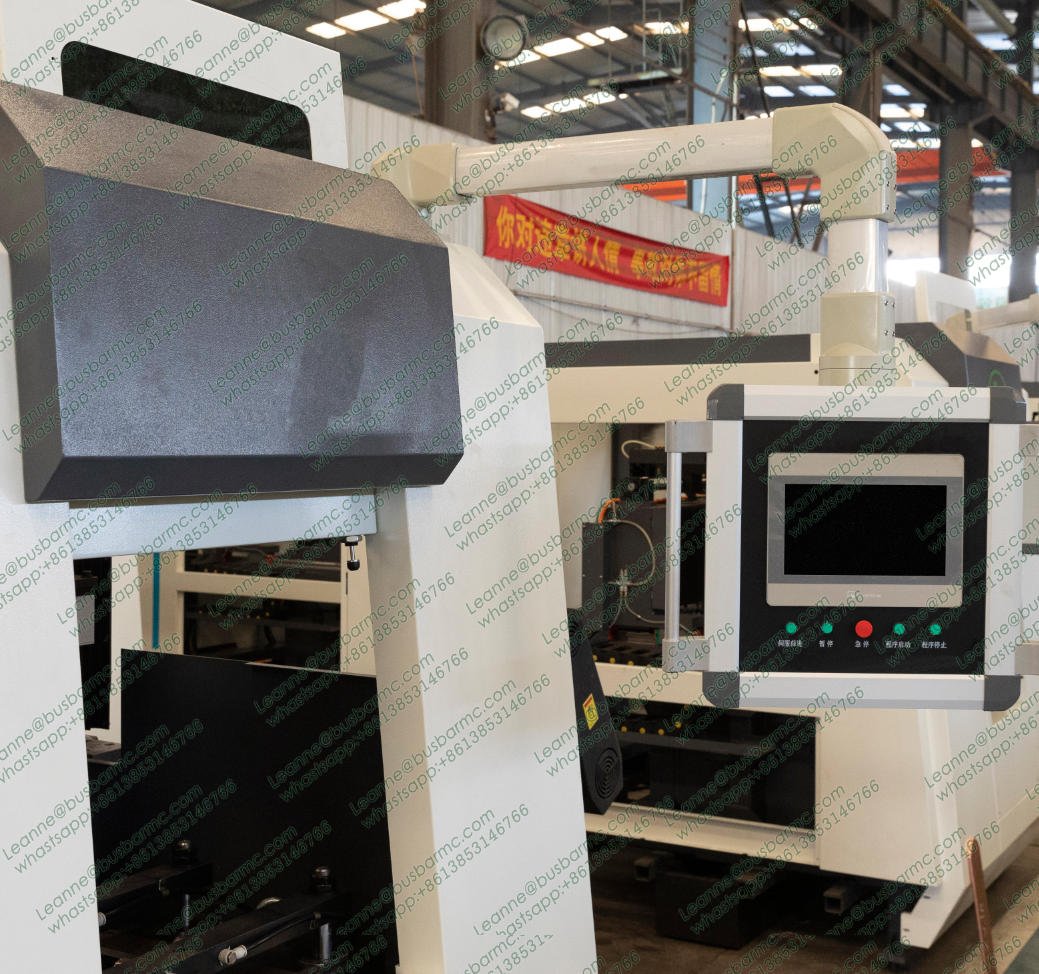

The machine is mainly composed of lathe bed workbench, gantry, slide rail, servo motor, power head and cylinder, fixture device, pneumatic system, CNC system, protective cover, etc.

Gantry-type mechanical structure adopts steel plate full-welded box structure, whose advantages are good rigidity and light weight of the lathe bed, meeting the requirements of rigidity of strong cutting of main spindle cutting tool and the requirement of sensitive feed response of moving parts.

The machine adopts high-precision ball screw and linear guide, and adopts high-load large-size guide in the selection of guide, making a better rigidity of the whole machine, reducing the vibration and noised, improving the work-piece quality, and ensuring the high precision and efficiency.

The spindle of the machine tool adopts the high-precision high-speed milling machine main shaft, which is installed integrally, and is driven by the variable-frequency motor with stepless speed change and the synchronous belt. It has the characteristics of a simple and reliable transmission structure, no need for lubrication, convenient cooling, high installation precision, high cutting speed, and the like.

A three-point positioning mode is adopted for workpiece positioning. After the workpiece is positioned, it is clamped by a workpiece clamping mechanism. The workpiece clamping mechanism adopts both pneumatic and hydraulic clamping, and has a stable speed without impact, a reliable clamping force, and easy adjustment.

The longitudinal (Y-direction) transmission and guide system of the machine tool is equipped with an organ-type protective cover to prevent flying dust from polluting the equipment.

The lathe bed is equipped with an in-line cutting tool magazine with six stations, which is convenient for the replacement and placement of commonly used working cutting tools.

The bottom of the machine tool body is provided with a chip collecting groove and a chip collecting trolley, which not only facilitates the collection of metal chips, but also saves the occupied area of the machine tool. Meanwhile, the device is simple and reliable.

The machine has the function of automatically accumulating working hours that cannot be reset. In addition, it has production counting function that can be reset.

The cutting tool of this machine adopts the formed cutting tool shearing. The cutting tool adopts the BT40 tool handle of the international standard with simple tool changing, good rigidity, and high precision. The in-line cutting tool magazine with six stations can automatically change the cutting tool according to the thickness of the busbar.

The machine is equipped with a water circulation system, and an automatic chip removal system is added.

The used components are well-known brands at home and abroad, with long service life and quality assurance.

Main Feature:

The equipment uses a dual-gantry spindle processing method, and during the busbar processing, no manual

intervention is required. It offers advantages such as fast processing speed, high precision, and high efficiency.

This equipment is mainly used for production lines but can also be used as a standalone machine.

The conveyors at both ends can be aligned with upstream and downstream equipment for seamless integration,

fully achieving automated production line operations. It is widely used in industries such as low and high-voltage

switchgear, switch cabinets, and box-type substations.

Technical Parameters:

CNCMN-200A CNC Busbar Chamfering Machine – Technical Parameters

| No. | Parameter Name | Unit | Parameter | Remarks |

|---|---|---|---|---|

| 1 | Maximum spindle speed | r/min | 6000 | |

| 2 | Main motor power | KW | 3.7 | |

| 3 | Model of spindle handle | - | BT40 | |

| 4 | X-axis working stroke | mm | 525 | Ensure copper busbars within R100 can be machined. |

| 5 | Y-axis working stroke | mm | 500 | Ensure copper busbars within width of 160 can be machined. |

| 6 | X-axis maximum operating speed | m/min | 15 | |

| 7 | Y-axis maximum operating speed | m/min | 15 | |

| 8 | X-axis positioning accuracy | mm | ±0.08 | |

| 9 | Y-axis positioning accuracy | mm | ±0.08 | |

| 10 | Thickness of workpiece | mm | 4–16 | 4–16 |

| 11 | Width of workpiece | mm | 30–200 | |

| 12 | Length of workpiece | mm | 150–6000 |

Control Mode

| No. | Parameter Name | Unit | Parameter | Remarks |

|---|---|---|---|---|

| 1 | Number of CNC axes | Piece | 5 | |

| 2 | Power of X-axis servo motor | KW | 2 | |

| 3 | Power of Y-axis servo motor | KW | 2 | |

| 4 | Hydraulic pump motor power | KW | 2.0 | |

| 5 | Working pressure of pneumatic system | MPa | 0.6–0.8 | |

| 6 | Machine dimensions (L×W×H) | mm | 2260×1580×2100 | Length does not include feeding table. |

| 7 | Machine weight | Kg | 2380 | |

| 8 | Total power | KW | 12 |

Main Components

| No. | Name | Quantity | Brand |

|---|---|---|---|

| 1 | Ball screw | 4 sets | HIWIN/TBI |

| 2 | Linear rolling guide | 8 sets | HIWIN/PEK |

| 3 | Servo driver | 4 sets | Rexroth |

| 4 | Servo motor | 4 sets | Rexroth |

| 5 | Pneumatic parts | 1 set | HSBC |

| 6 | Hydraulic components | 1 set | Shanghai Fengyi |

| 7 | Spindle servo | 1 set | Jing Yao |

| 8 | Programmable controller | 1 set | BECKHOFF, Germany |

Optional Accessories:

| No. | Item | Quantity | Description |

| 1. | Milling cutter | 6 sets | 4mm, 5mm, 6mm, 8mm, 10mm, 12mm |

| 2. | Tool holder device | 1 set | |

| 3. | Screwdrivers | 2 sets | 2 bigger screwdrivers, 2 small screwdrivers |

| 4. | Inductive proximity sensor | 1 pc | |

| 5. | Double-head wrench | 1 set | |

| 6. | Oil sprayer | 1 pc | |

| 7. | Oil lubrication box | 1 pc | |

| 8. | Bending shaft hole cover | 6 pcs | |

| 9. | Oil hose | 1 pc |

Video: