High-precision CNCMN-200A CNC busbar chamfering machine for copper and aluminum busbars. Features gantry structure, BT40 tool holder, 6-station automatic tool changer, 5-axis CNC control, and fast arc/chamfer milling for 4–16 mm busbars.

CNCMN-200A CNC BUSBAR CHAMFERING MACHINE

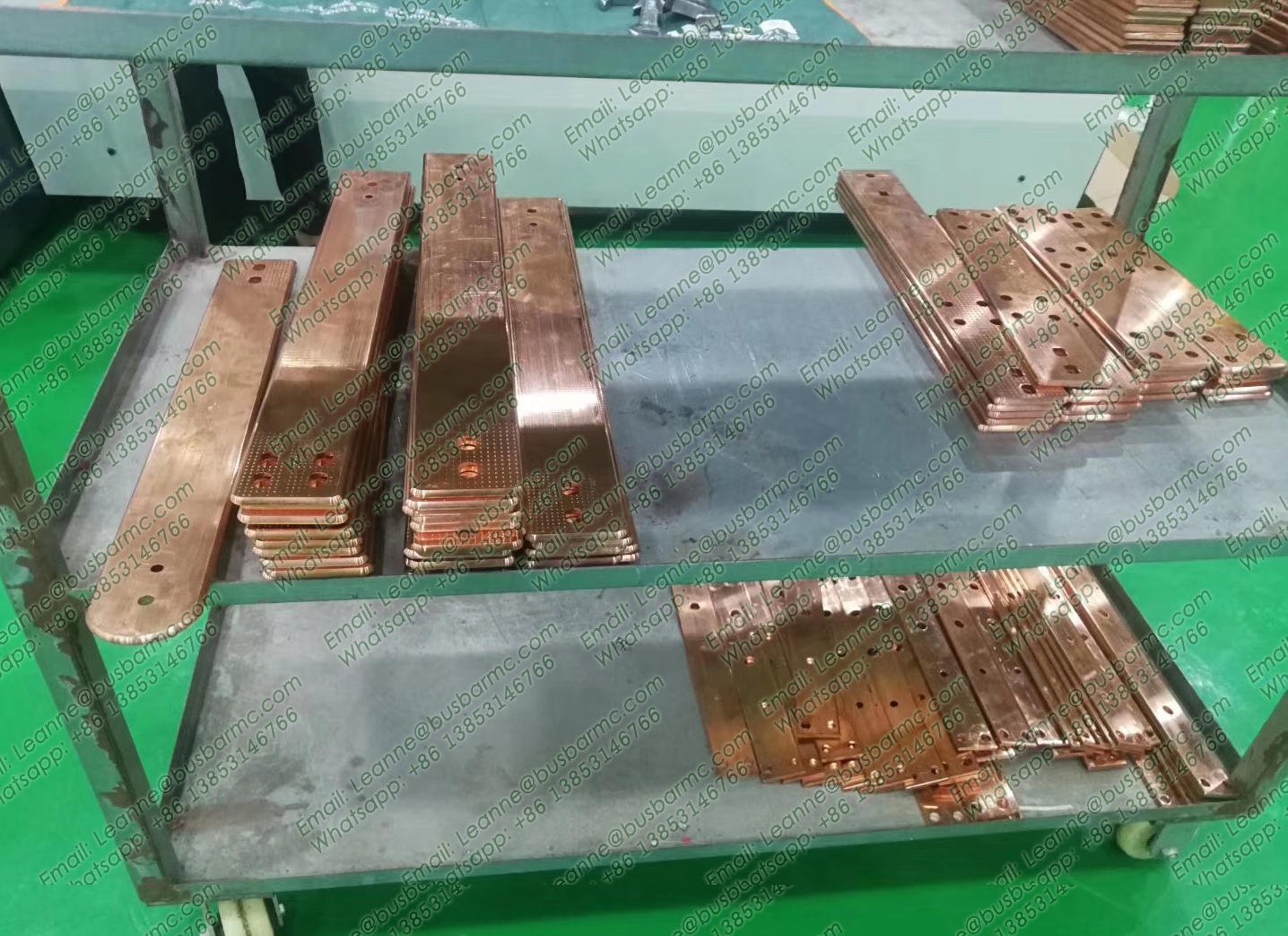

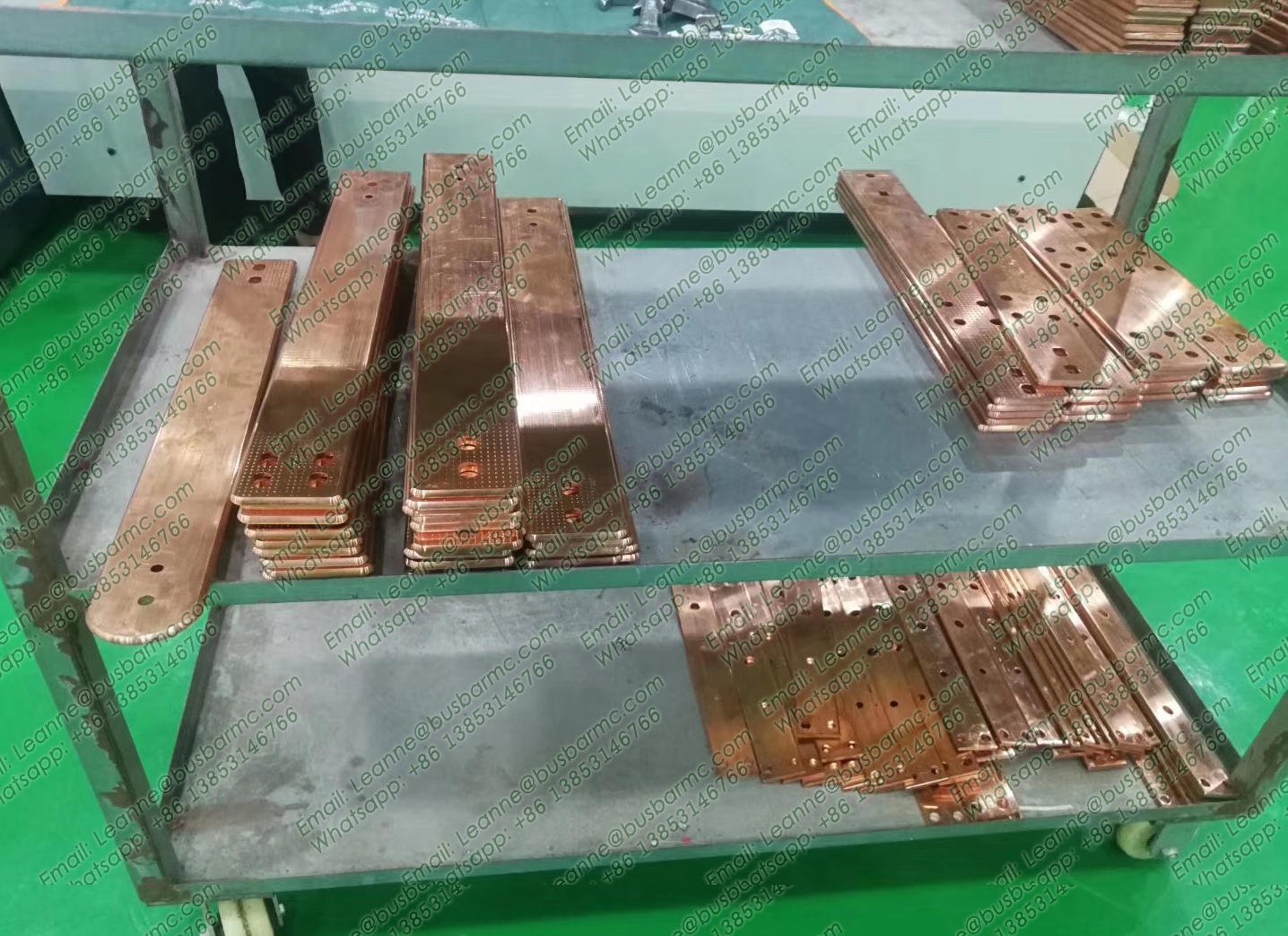

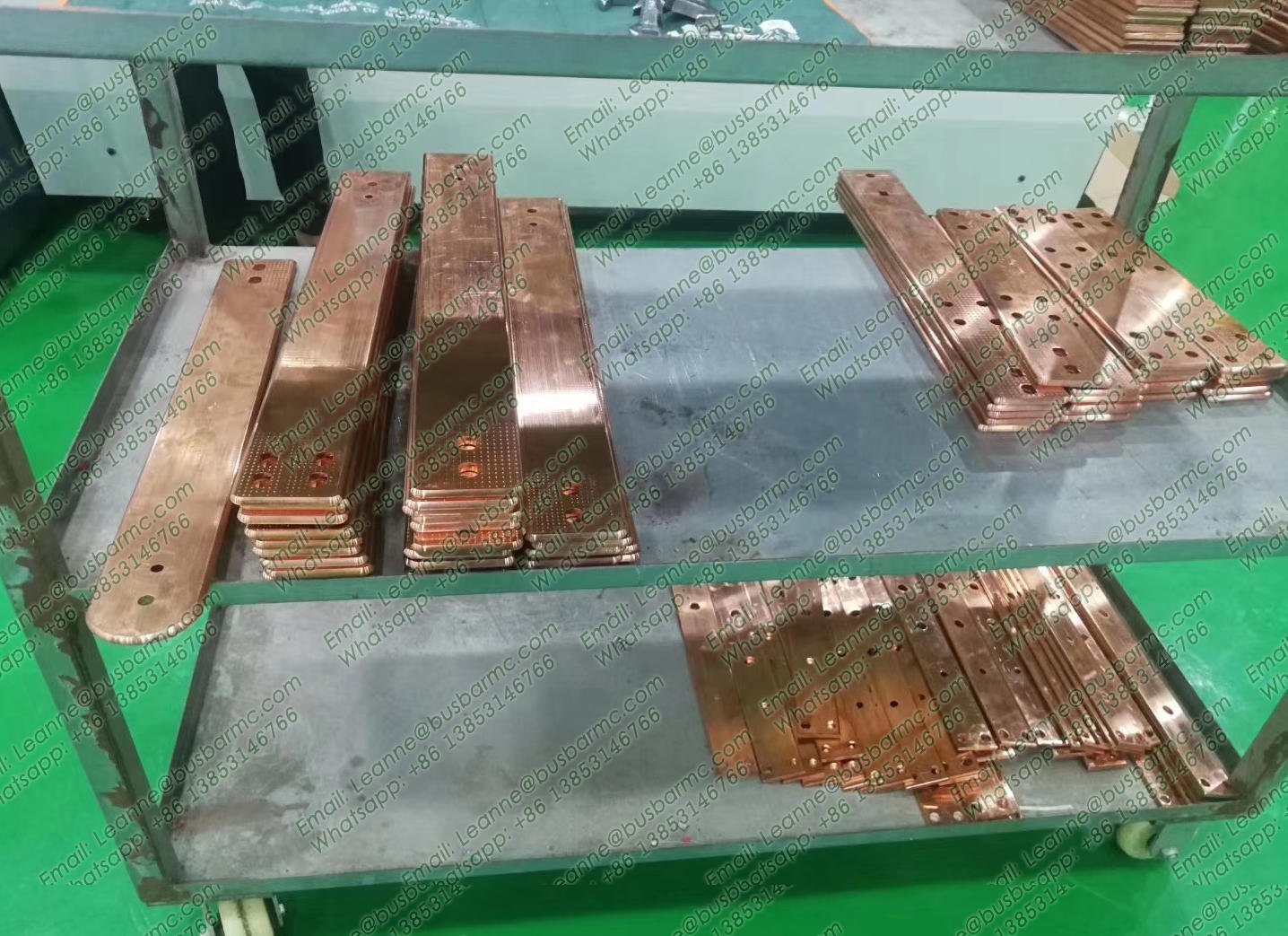

The main function of the busbar arc processing center is to perform chamfering (arc) processing on the ends of copper and aluminum busbars.

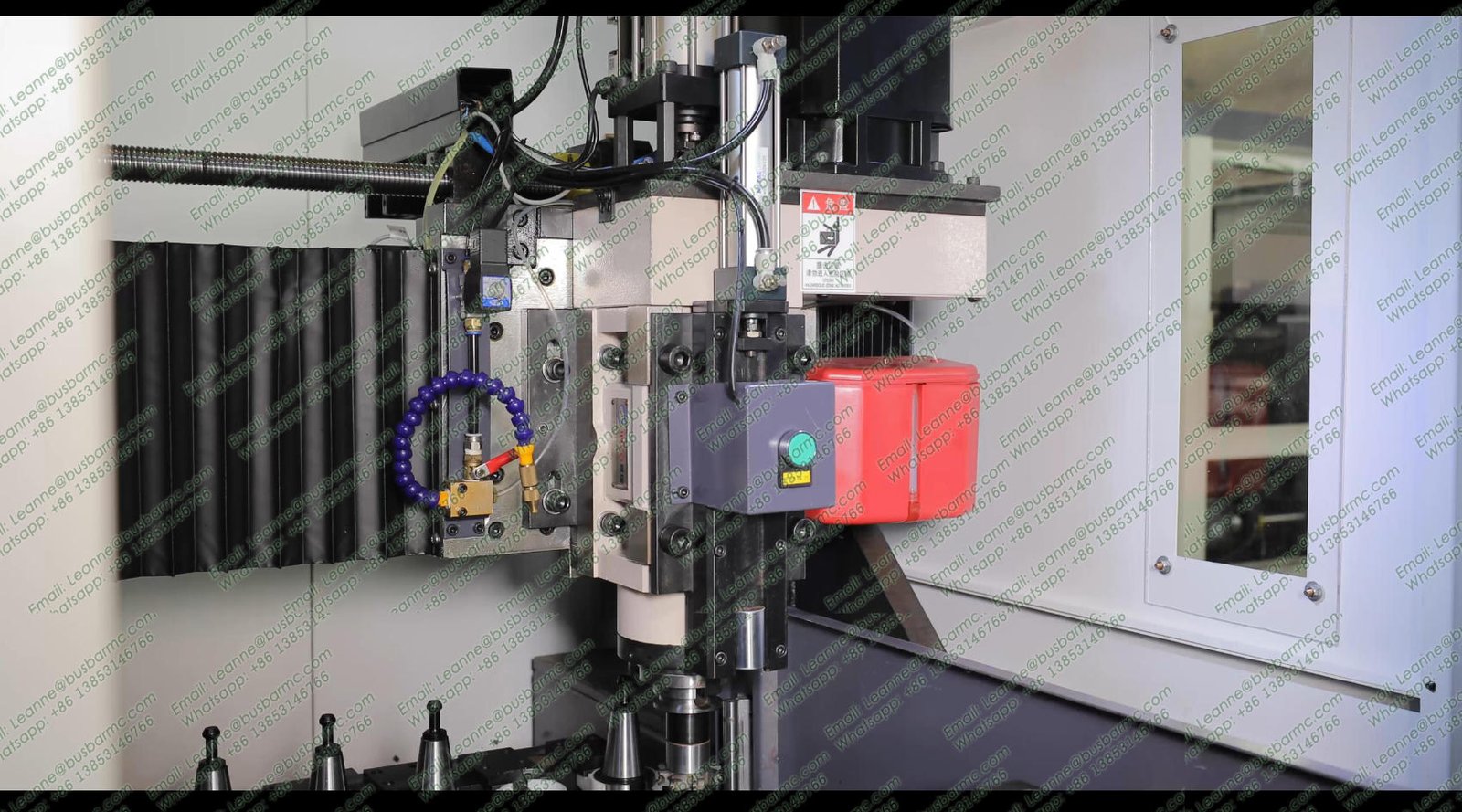

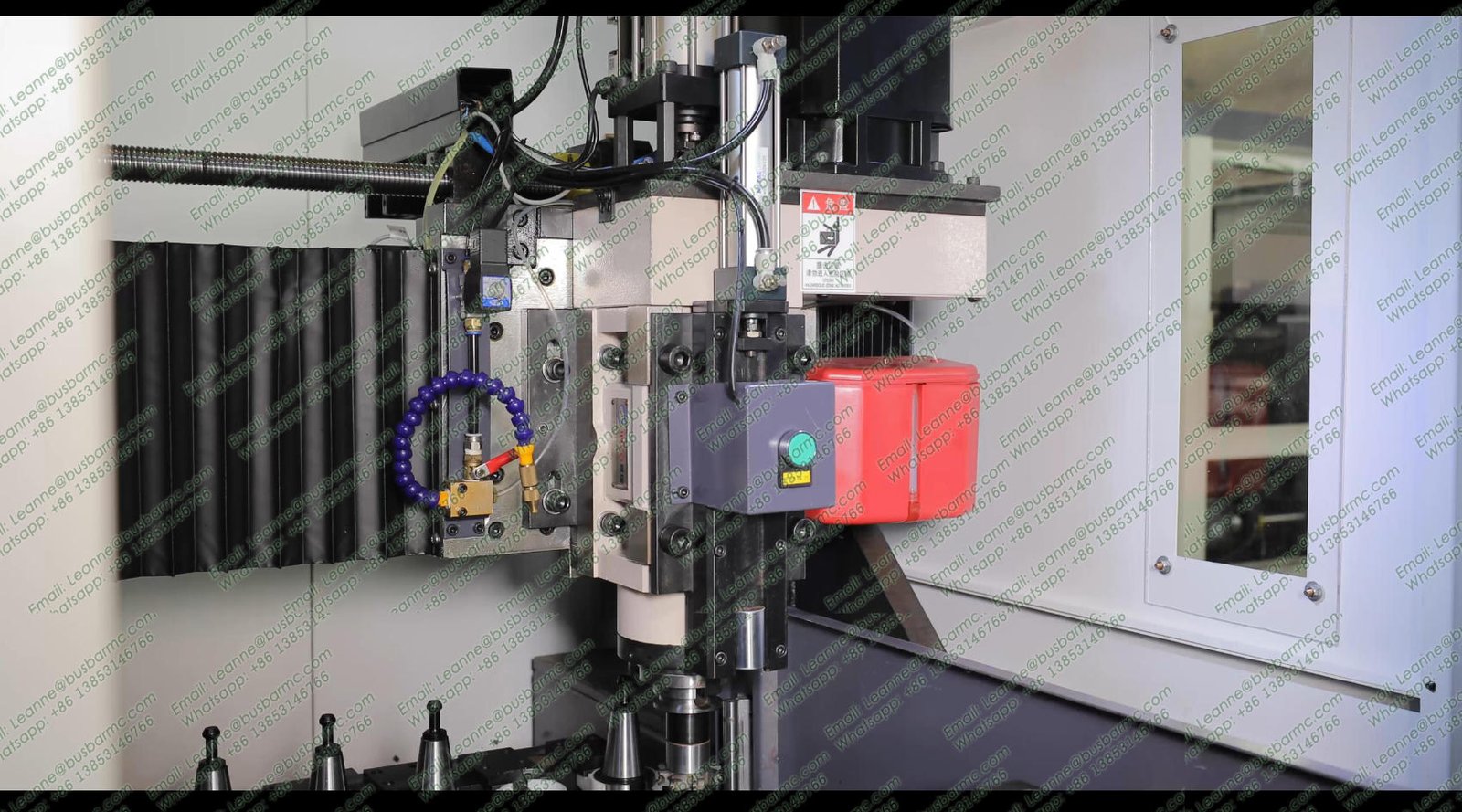

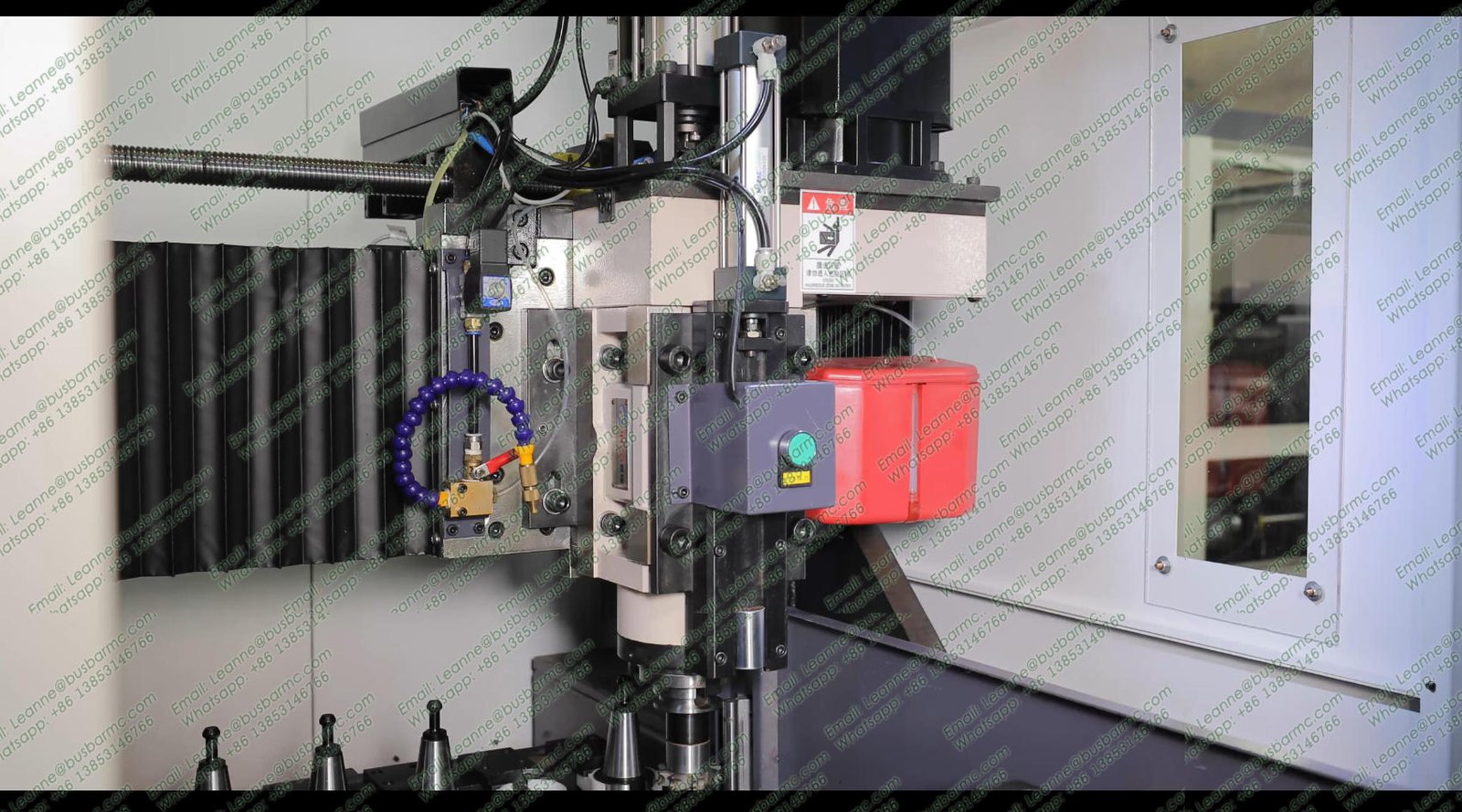

▲ Gantry mechanical structure, simple design, stable operation, good structural rigidity.

▲ Six-station inline tool magazine, automatic tool change.

▲ Tool holder, international standard BT40 tool holder, simple tool change, good rigidity, high precision.

▲ Two-axis control system, simple operation and convenient maintenance.

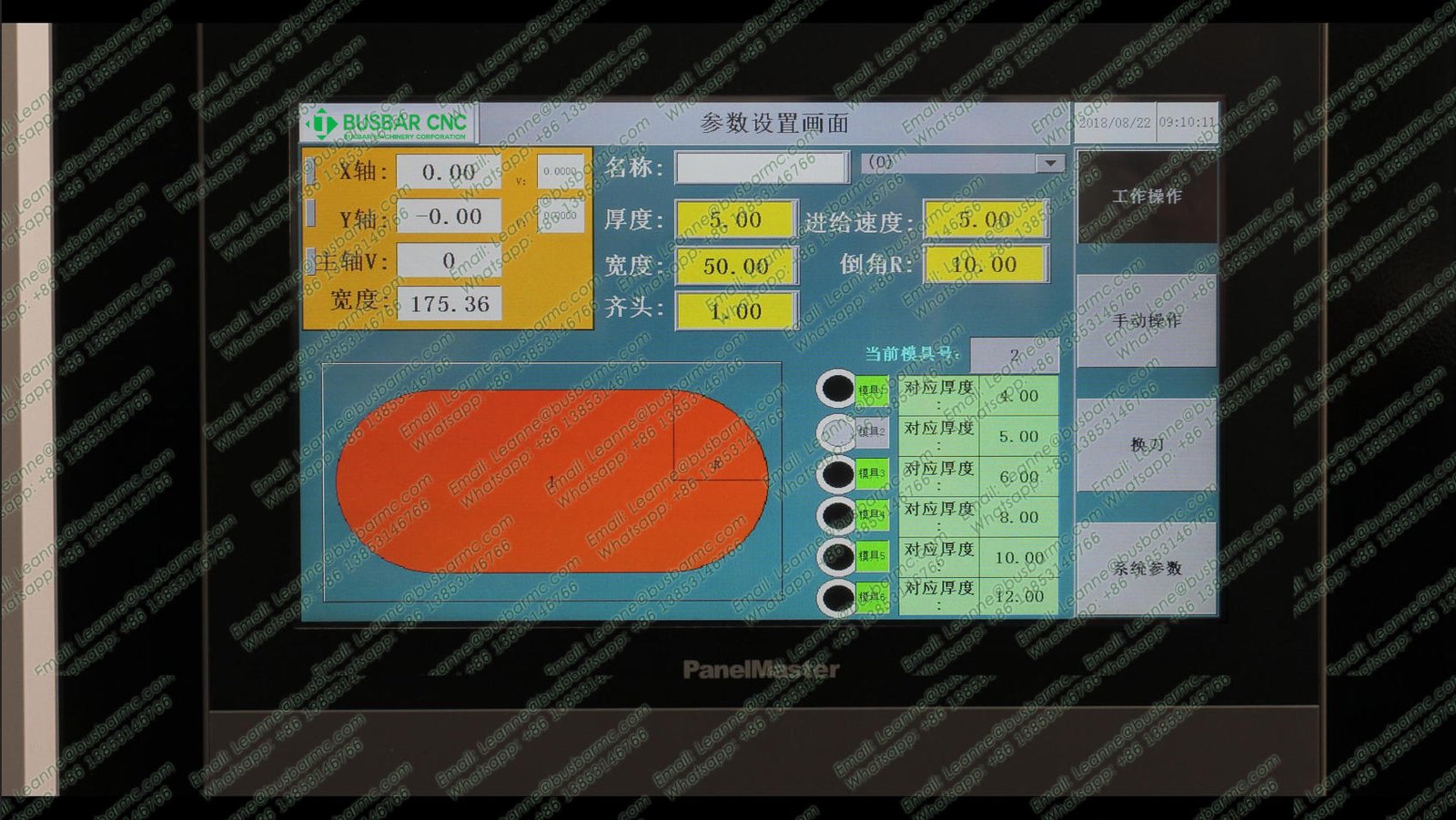

▲ Human-machine interface, clear interface, simple operation.

| No. | Technical Parameters | Unit | Value | No. | Technical Parameters | Unit | Value |

|---|---|---|---|---|---|---|---|

| 1 | Maximum spindle speed | r/min | 6000 | 2 | Main motor power | KW | 3.7 |

| 3 | Maximum X-axis travel | mm | 525 | 4 | Maximum speed of X axis | m/min | 15 |

| 5 | X-axis positioning accuracy | mm | ±0.08 | 6 | Maximum travel of X axis | mm | 500 |

| 7 | Maximum Y-axis speed | m/min | 15 | 8 | Positioning accuracy of Y axis | mm | ±0.08 |

| 9 | Maximum Z-axis travel | mm | 130 | 10 | Positioning accuracy of Z axis | mm | ±0.05 |

| 11 | Workpiece length that can be processed | mm | 150-6000 | 12 | Machinable workpiece width | mm | 30-200 |

| 13 | Machinable workpiece thickness | mm | 4-16 | 14 | Dimensions | mm | 2260×1580×2100 |

Control method

| No. | Technical Parameters | Unit | Value | No. | Technical Parameters | Unit | Value |

|---|---|---|---|---|---|---|---|

| 1 | Number of CNC axes | PC | 5 | 2 | X-axis servo motor power | KW | 2 |

| 3 | Y-axis servo motor power | KW | 2 | 4 | Z-axis servo motor power | KW | 1 |

| 5 | Air source pressure | MPa | 0.6-0.8 | 6 | Hydraulic pump motor power | KW | 2 |

| 7 | Total power | KW | 12 | ||||

Infomation:

1. Main purpose:

The main function of this machine is to perform arc processing on the ends of copper bars, and is used for milling angles, arc angles and other external processing of copper-aluminum busbars with a thickness of 4-16mm and a width of 30-200. It has a simple structure and is easy to use.

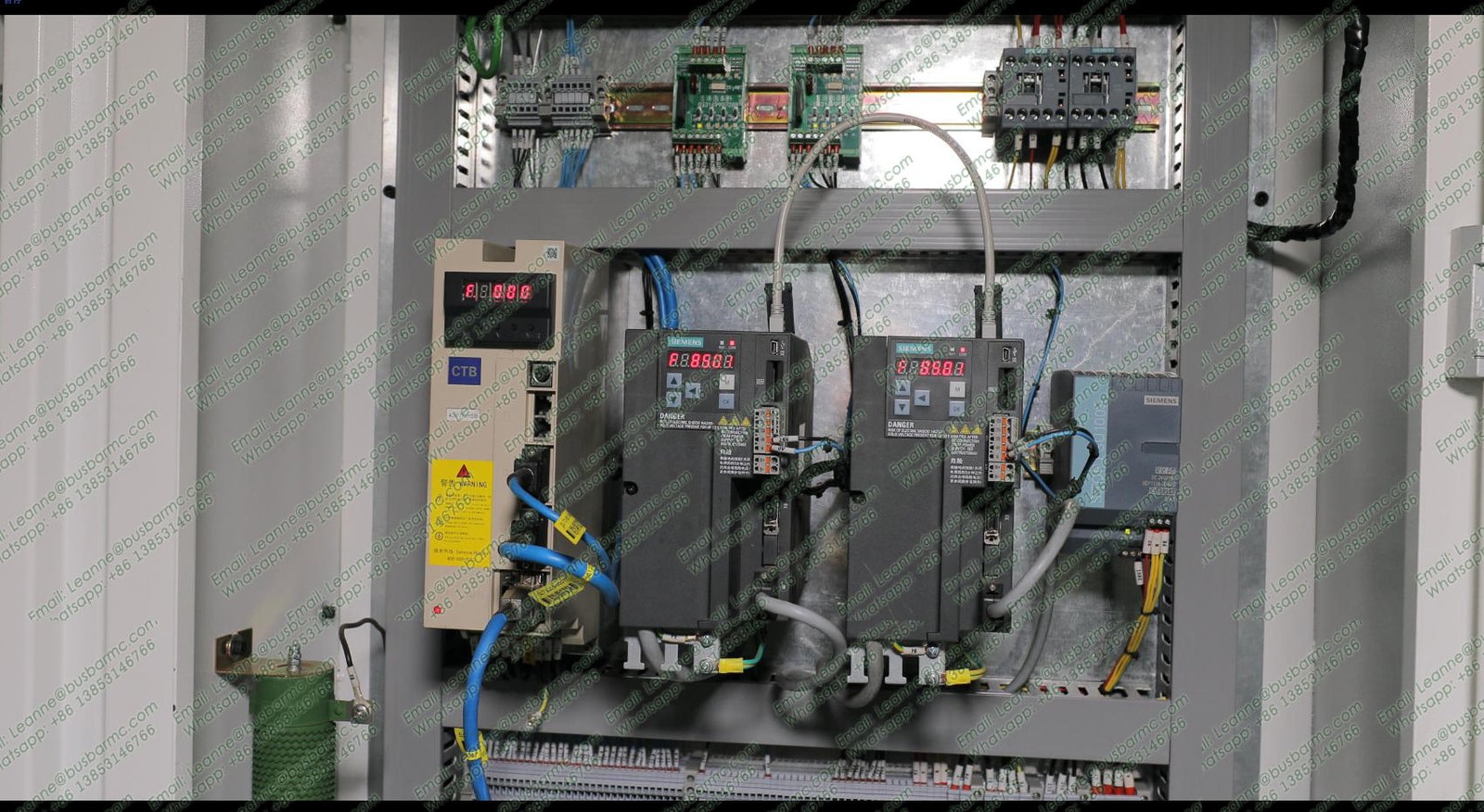

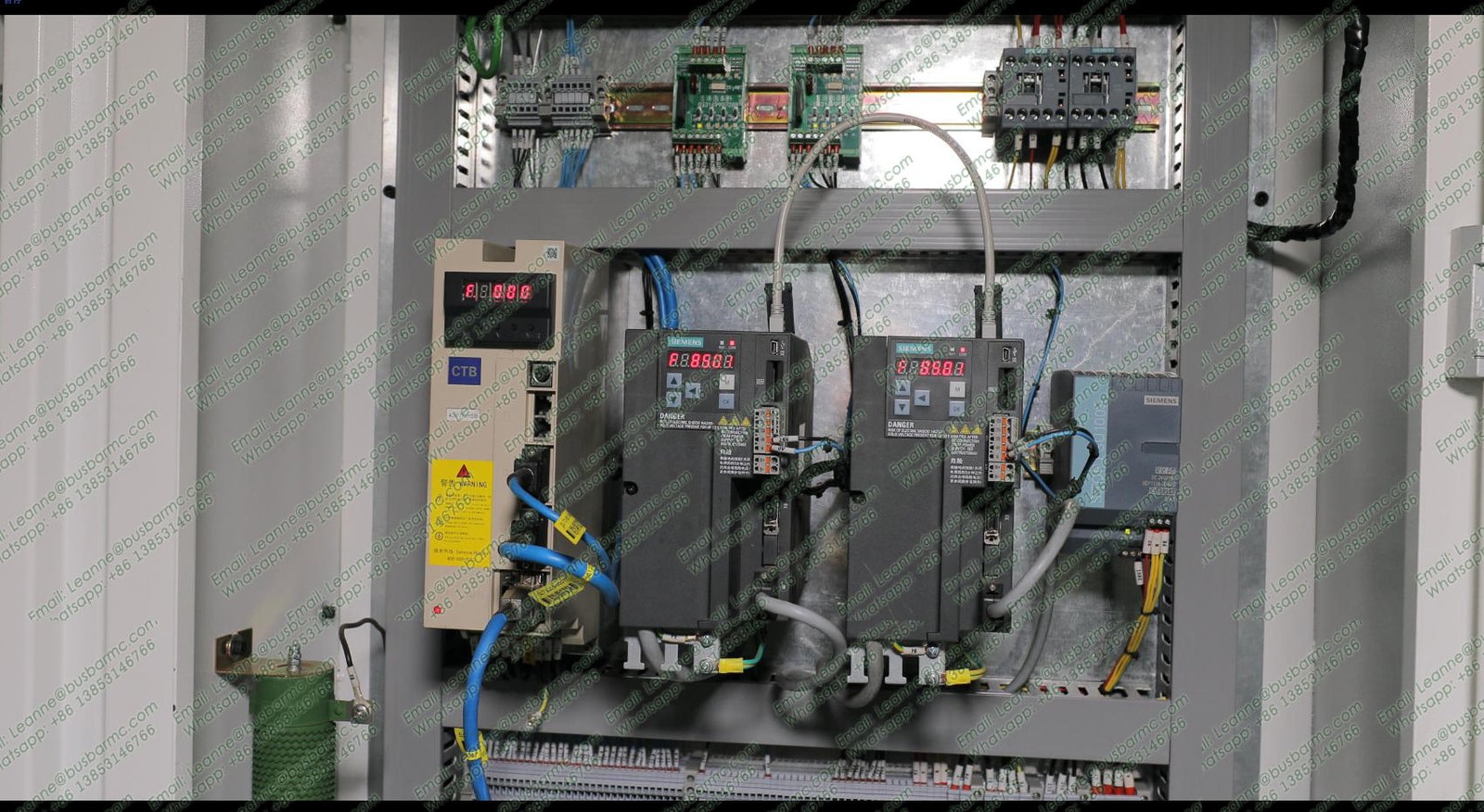

2. Control method:

The electrical control adopts a 5-axis CNC system control, and the feeding and cutting of the copper bar are completed by starting and running the spindle motor and servo motor, and the clamping or loosening of the tool is completed by pneumatic control.

It adopts a five-axis CNC automatic control system and is equipped with a 10.4″ LCD display to display the working status of the machine tool. It can store, count the workload, display and communicate according to the input work sequence number, simulate operation processing and manual online programming functions.

3. Machine structure, advantages and operating characteristics:

The machine mainly consists of a bed worktable, gantry, slide rail, servo motor, power head and cylinder, fixture device, pneumatic system, CNC system, protective cover and other parts.

The gantry mechanical structure adopts a box structure in the form of fully welded steel plates. Its advantages are that the bed has good rigidity and light weight, which can meet the rigidity requirements of the spindle tool for strong cutting and the requirements of sensitive feeding response of moving parts.

The machine adopts high-precision ball screws and linear guides. High-load large guides are used in the selection of guides to make the whole machine more rigid, reduce vibration and noise, improve the quality of workpieces, and ensure high precision and high efficiency.

The machine tool spindle adopts an integrally installed high-precision high-speed milling machine spindle, which is driven by a variable frequency motor with stepless speed change and synchronous belt drive. It has the characteristics of simple and reliable transmission structure, no lubrication, easy cooling, high installation accuracy and high cutting speed.

The workpiece positioning adopts a three-point positioning method. After the workpiece is positioned, it is clamped by the workpiece clamping mechanism. The workpiece clamping mechanism adopts pneumatic and hydraulic double clamping, with stable speed and no impact, reliable clamping force, and easy adjustment.

The longitudinal (Y-direction) transmission and guide system of the machine tool is equipped with an accordion-type protective cover for protection to prevent flying dust from polluting the equipment. The bed is arranged with a six-station inline tool magazine, which is convenient for the replacement and placement of commonly used tools.

The bottom of the machine bed is equipped with a chip collection groove and a chip collection trolley, which is convenient for the collection of metal chips and can save the floor space of the machine tool. At the same time, the device is simple and reliable.

This machine has the function of automatically accumulating working hours, and it cannot be reset. In addition, it has a production counting function and can be reset.

The tool of this machine adopts forming tool cutting, and the tool adopts the international standard BT40 tool holder, which is simple to change the tool, good rigidity and high precision. The six-station inline tool magazine can automatically replace the tool according to the thickness of the busbar.

This machine has a water circulation function system and an automatic chip removal system.

The components used are well-known domestic and foreign brands with long service life and quality assurance.

Main equipment components and supplier information

| NO | Name | Brands | QTS |

|---|---|---|---|

| 1 | Central Processing Unit (PLC) | Beckhoff, Germany | 1 |

| 2 | Servo Motor | Rexroth, Germany | 3 |

| 3 | Servo Drive | Rexroth, Germany | 3 |

| 4 | Ball Screw | TBI, Taiwan | 3 |

| 5 | Linear Rolling Guide | Hiwin, Taiwan | 3 |

| 6 | Pneumatic Parts | HSBC | 1 |

| 7 | Hydraulic Parts | Shanghai Fengyi | 1 |

| 8 | Spindle | Jingyao | 1 |

Video:

Q1: What is the main function of the CNCMN-200A CNC busbar chamfering machine?

The main function is to perform chamfering, arc milling, and edge processing on copper and aluminum busbar ends with thickness 4–16 mm and width 30–200 mm.

Q2: What type of structure does this machine use?

The machine uses a gantry mechanical structure with a fully welded steel plate box design, providing high rigidity, stable operation, and strong cutting performance.

Q3: How many tools can the machine hold?

It is equipped with a six-station inline tool magazine that supports automatic tool change using BT40 tool holders.

Q4: What CNC control system does the machine use?

The machine adopts a 5-axis CNC control system with a 10.4" LCD display, capable of program storage, workload counting, simulation, and manual online programming.

Q5: What is the maximum processing size of the busbar?

The machine can process busbars with length 150–6000 mm, width 30–200 mm, and thickness 4–16 mm.

Q6: What is the spindle speed of the CNCMN-200A?

The maximum spindle speed is 6000 r/min, using a high-precision integrated milling spindle driven by a variable-frequency motor.

Q7: What components are used in the machine?

The machine uses high-quality international and domestic brands such as Beckhoff PLC, Rexroth servo motors/drives, TBI ball screws, Hiwin linear guides, HSBC pneumatic parts, and Jingyao spindle units.

Q8: Does the machine have an automatic chip removal system?

Yes, it includes a water circulation system and an automatic chip removal device, along with a chip collection groove and trolley for easy cleaning.

Q9: How is the workpiece clamped?

The machine uses a three-point positioning method combined with pneumatic + hydraulic double clamping for stable, reliable, and impact-free holding.

Q10: What are the power requirements of the machine?

The total power is 12 kW, including spindle motor, servo motors (X/Y/Z), and hydraulic pump motor.

Q11: What safety or protection features are included?

The Y-axis guide system has an accordion protective cover to prevent dust intrusion, and the machine includes a full enclosure for safer operation.

Q12: Does the machine support automatic tool change based on busbar thickness?

Yes, the six-station tool magazine can automatically replace tools according to the busbar thickness and processing sequence.

Q13: Is production counting available?

Yes, the machine can automatically accumulate working hours and includes a resettable production counting function.