Integrated pneumatic dot peen marking machine designed for copper and aluminum busbar processing. Provides fast and durable marking for text, serial numbers, and codes, suitable for CNC busbar fabrication lines, switchgear manufacturing, and power distribution cabinet production.

Pneumatic Marking Machine for Busbar Processing | Integrated Dot Peen Marking System for Copper & Aluminum Busbars

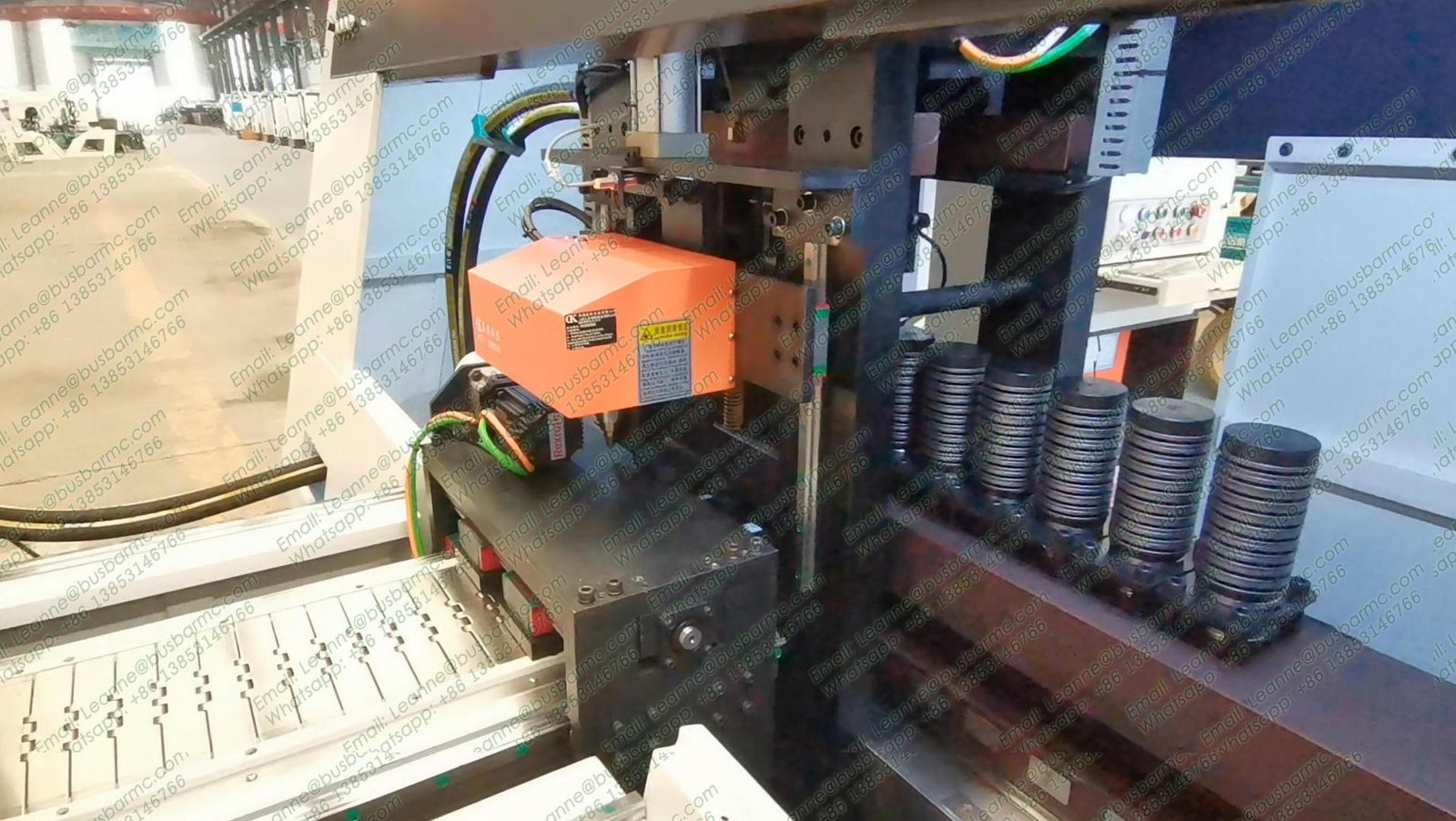

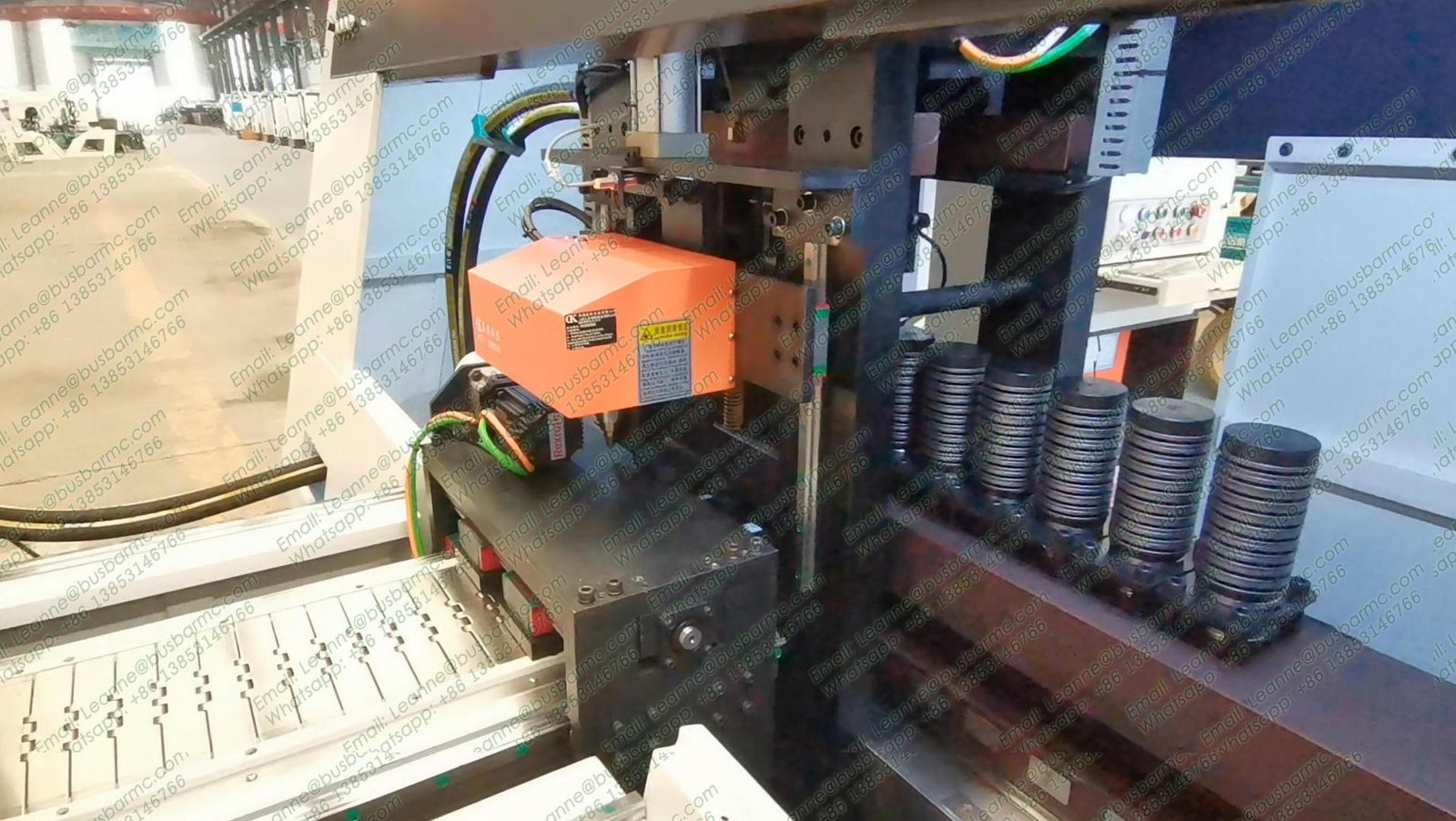

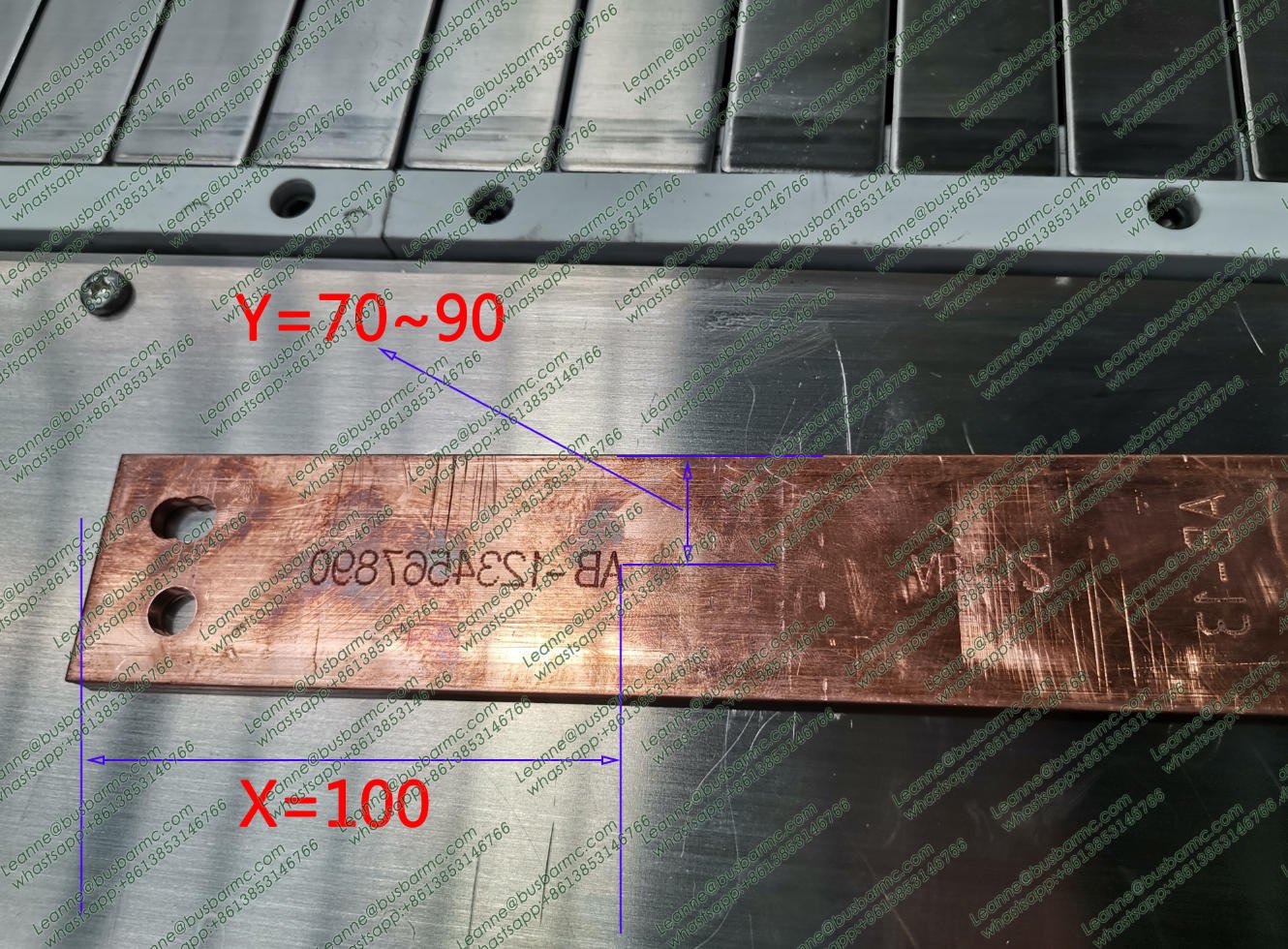

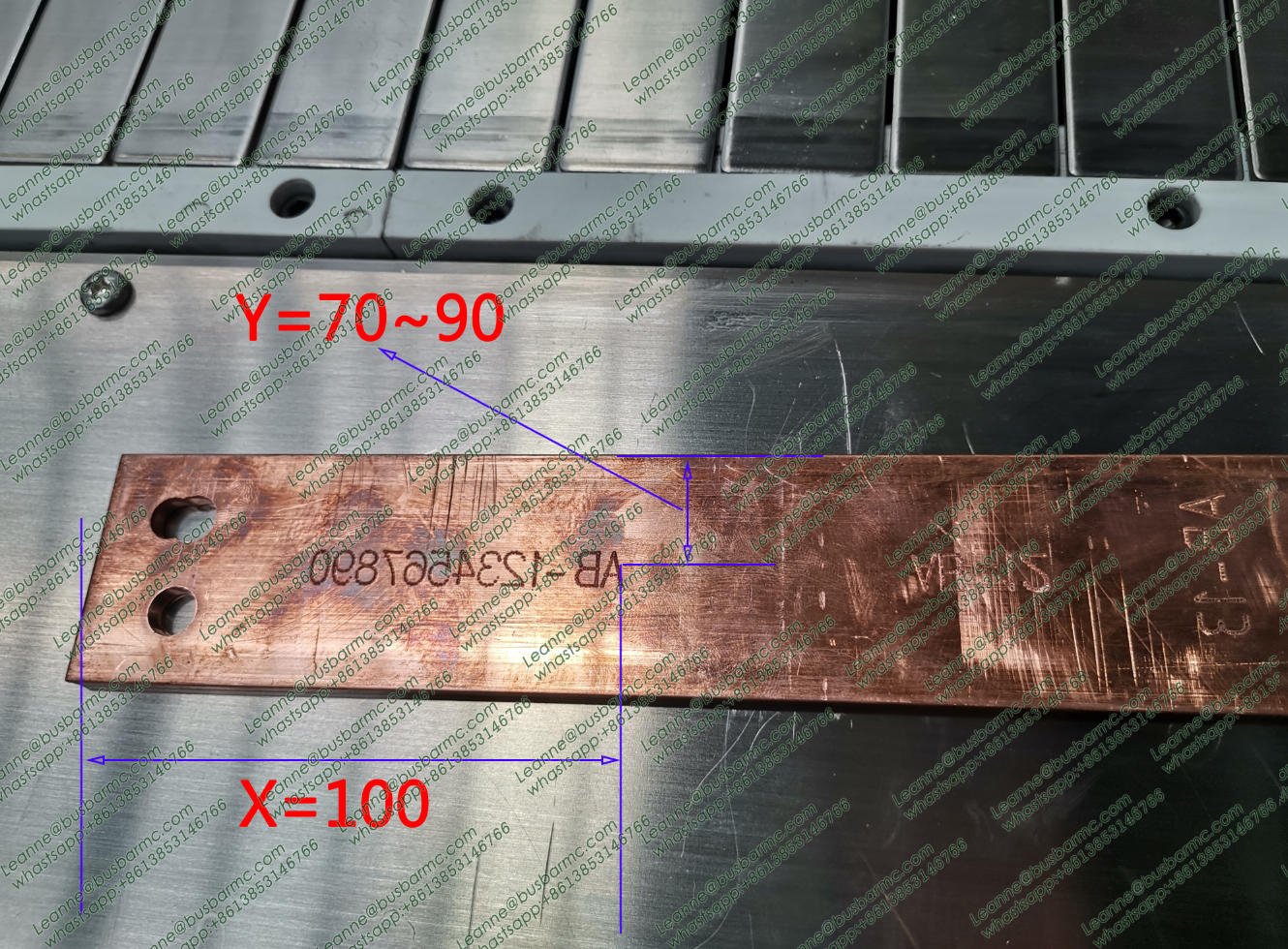

our Pneumatic Marking Machine integrated with a Busbar Processing Machine, designed to achieve fast, clear, and permanent dot-peen marking on copper and aluminum busbars.

The system is ideal for factories that need automatic marking during busbar punching, bending, cutting, and assembly.

Integrated dot-peen pneumatic marking system for busbar production

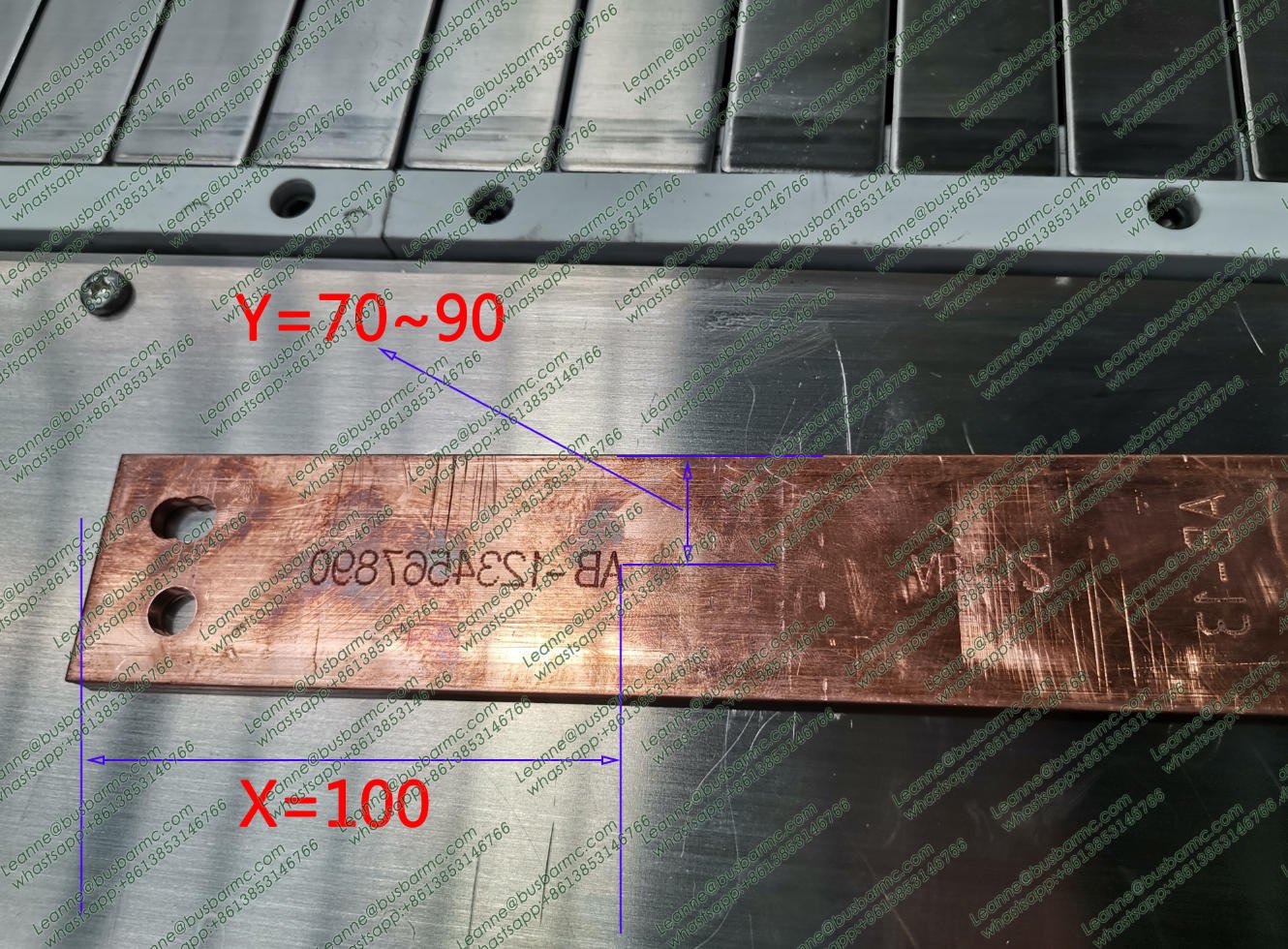

Suitable for copper & aluminum busbars (5–15 mm thickness)

Marks text, serial numbers, batch codes, and simple logos

High marking speed and deep engraving for durable results

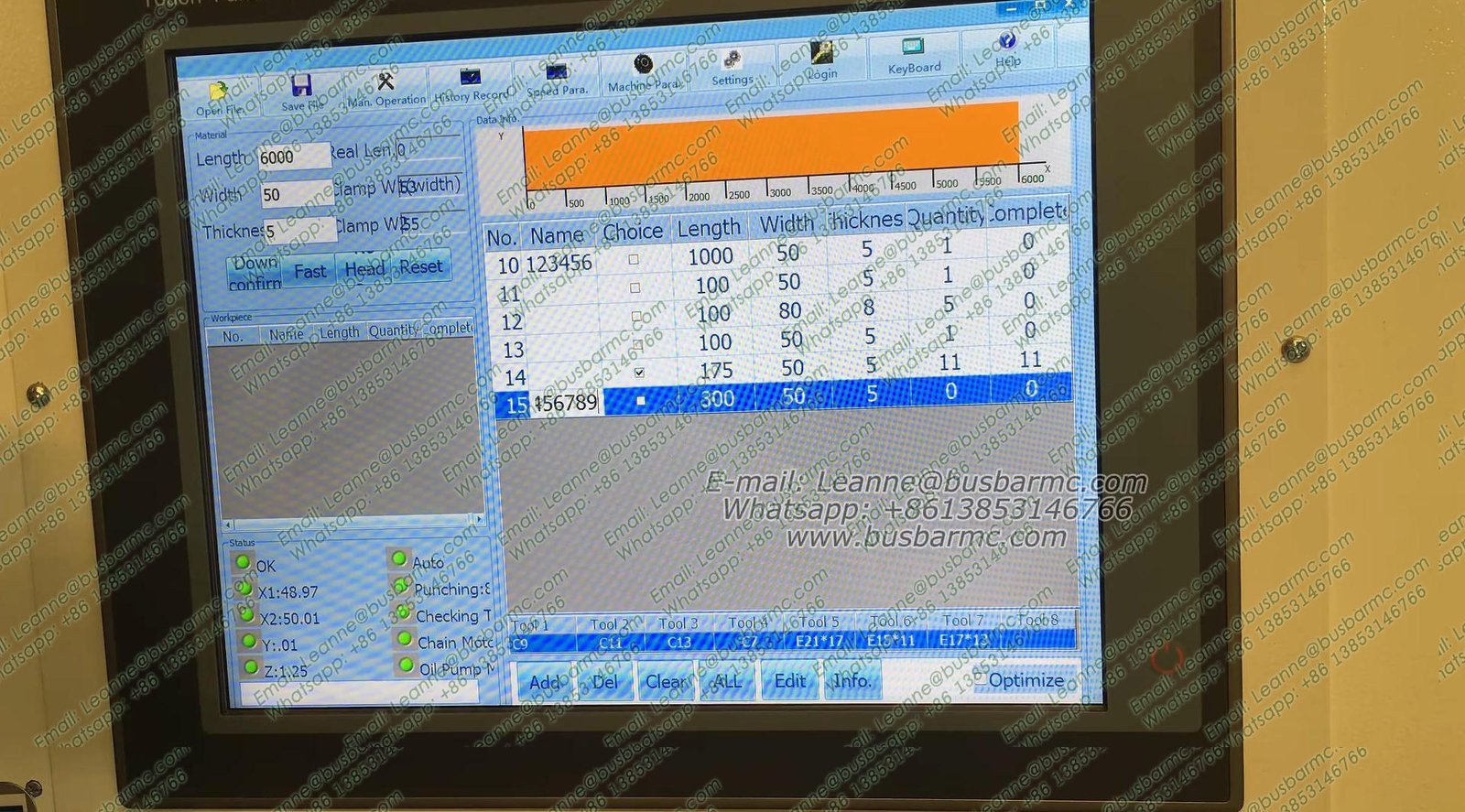

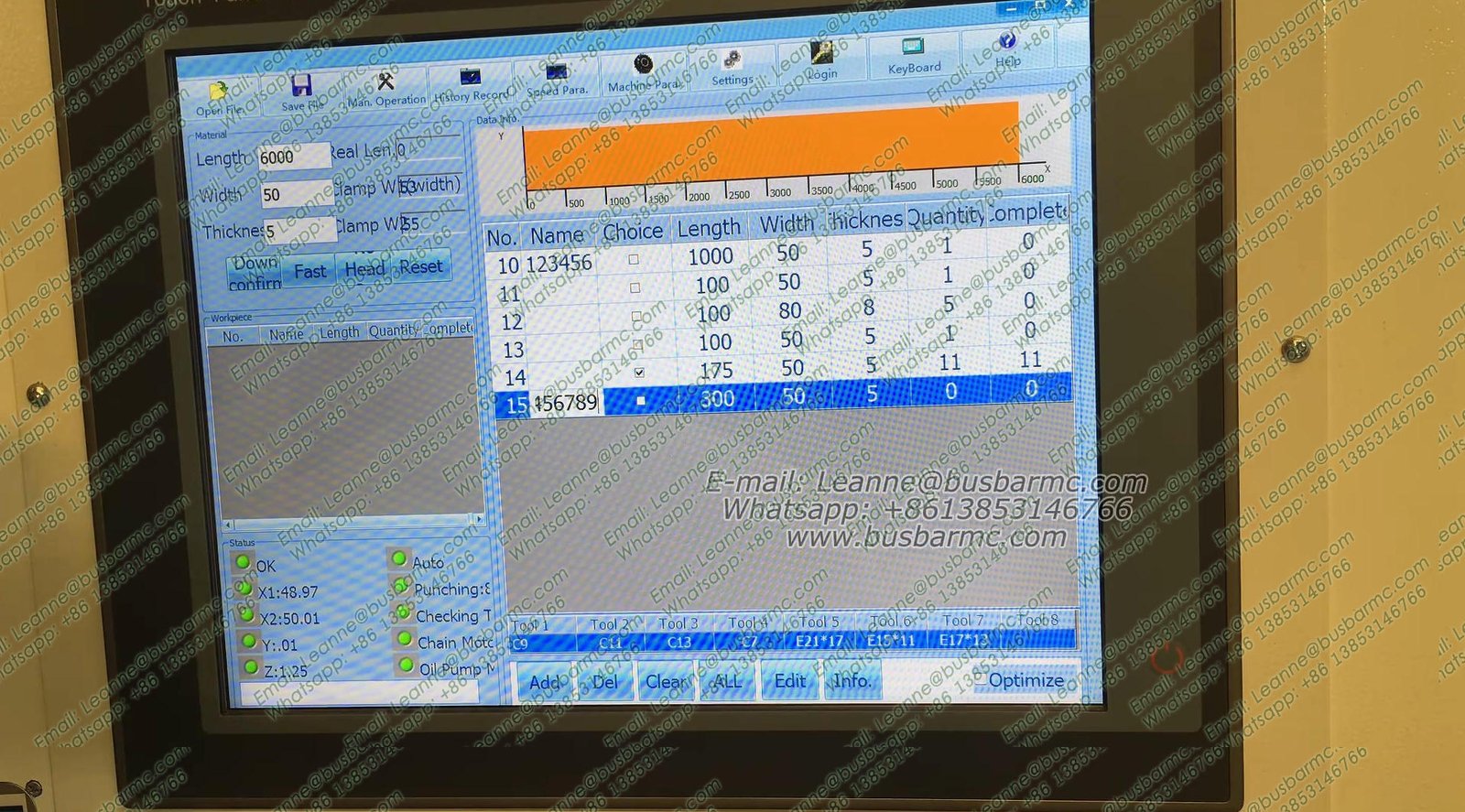

Compatible with CNC busbar fabrication machines

Stable structure, low maintenance, long service life

Busbar fabrication workshops

Electrical switchgear manufacturing

Power distribution cabinet production

Substation & transformer component factories

This integrated pneumatic marking device is perfect for improving workflow efficiency and product traceability in busbar production lines.

Busbar machine pneumatic marking video:

Tags:

pneumatic marking machine,busbar pneumatic marking,dot peen marking machine,busbar processing machine,busbar fabrication equipment,copper busbar marking,aluminum busbar marking,integrated marking system,busbar production line marking,busbar punching bending cutting machine,pneumatic engraving machine,dot peen engraver for metal,busbar automation equipment,industrial marking system,busbar identification marking

| Item | Specification |

| Marking Method | Pneumatic Dot Peen Marking |

| Applicable Materials | Copper Busbar, Aluminum Busbar, Metal Plates |

| Busbar Thickness | 5 – 15 mm |

| Marking Depth | 0.01 – 1.0 mm Adjustable |

| Marking Speed | Up to 5 Characters / Second |

| Marking Content | Text, Serial Numbers, Dates, Batch Codes, Simple Logos |

| Air Pressure | 0.2 – 0.6 MPa |

| Power Supply | AC 110V / 220V, 50/60Hz |

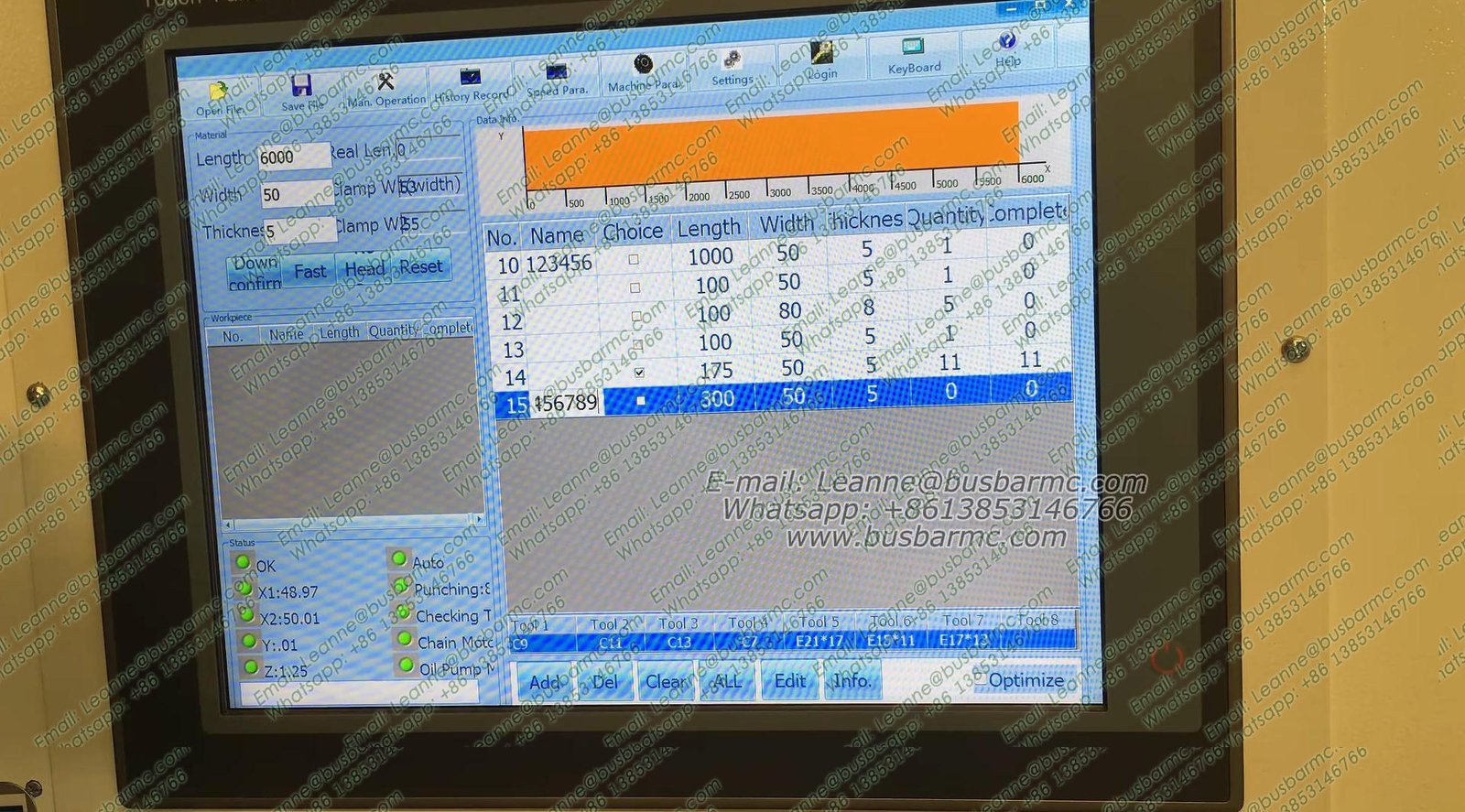

| Control System | Industrial Controller / CNC Interface |

| Integration Type | Integrated with Busbar Punching, Bending and Cutting Machine |

| Operating Mode | Automatic Online Marking |

| Service Life | ≥ 100,000 Hours |

Q1: What materials can this pneumatic marking machine mark?

It is mainly designed for copper and aluminum busbars, and also suitable for common metal materials used in electrical equipment.

Q2: Can this marking machine work automatically with a busbar CNC machine?

Yes. The marking system can be fully integrated with CNC busbar punching, bending and cutting machines for automatic online marking.

Q3: How deep is the marking?

The marking depth is adjustable from 0.01 mm to 1 mm, ensuring clear and permanent identification.

Q4: What kind of information can be marked?

It supports text, serial numbers, dates, batch codes, barcodes, QR codes and simple logos.

Q5: What air pressure is required?

A stable compressed air supply of 0.2–0.6 MPa is required for smooth and stable marking.

Q6: What voltage does the machine use?

The standard power supply is AC 110V or AC 220V, 50/60Hz, suitable for most countries.

Q7: Is the machine suitable for mass production?

Yes. It is designed for continuous high-speed operation in industrial busbar production lines.

Q8: What maintenance is required?

Only basic maintenance is needed, including regular cleaning, air system inspection and needle replacement when necessary.