LT HQ400-B CNC Busbar Bending Machine:Precision Automation for Electrical Fabric

LT HQ400-B CNC Busbar Bending Machine:Precision Automation for Electrical Fabrication busbar machine

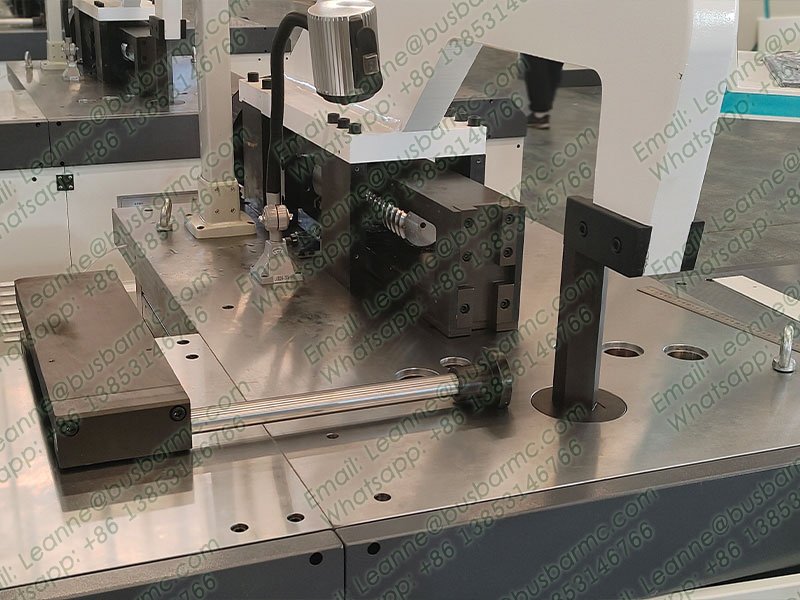

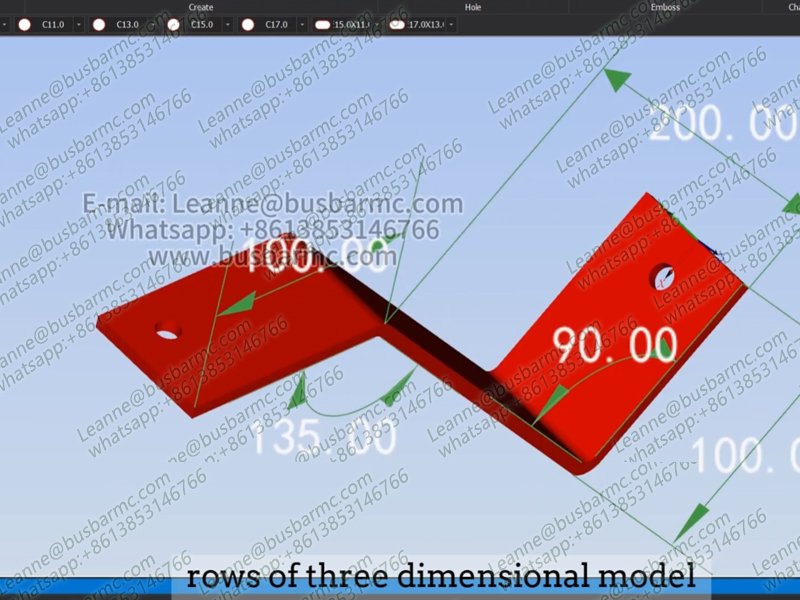

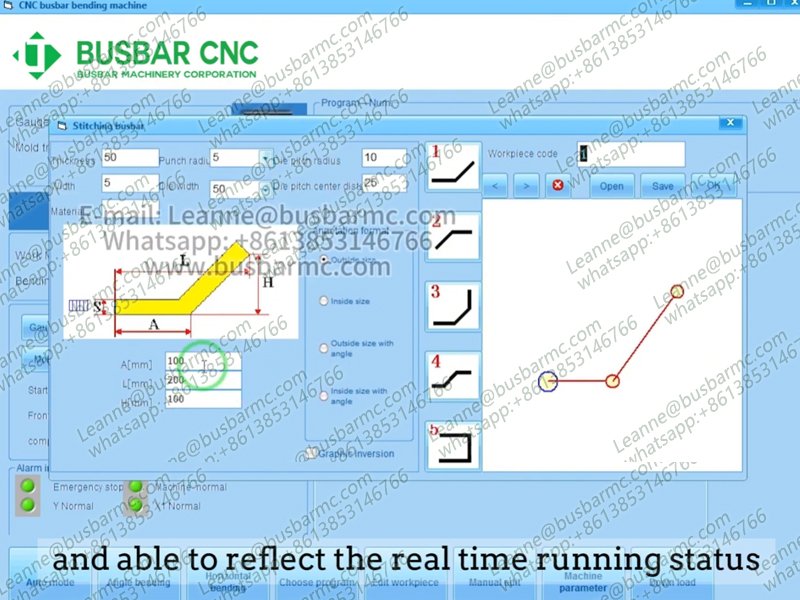

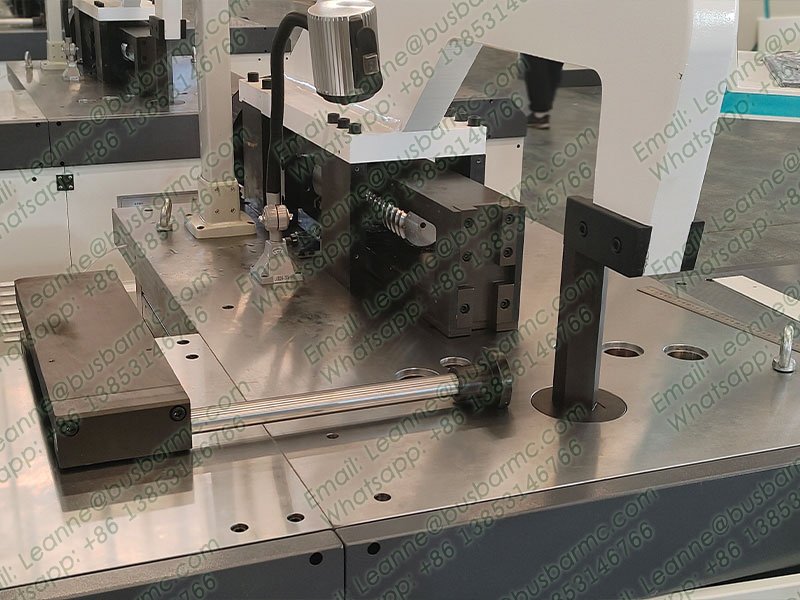

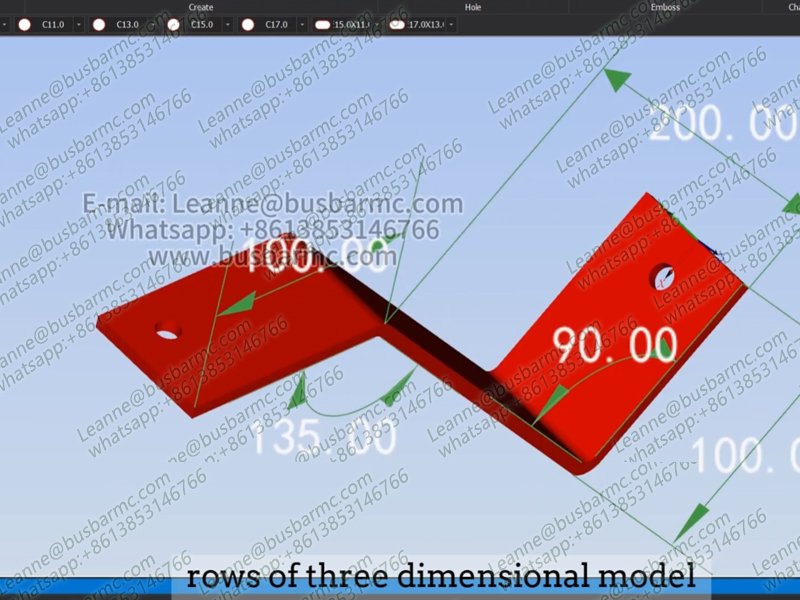

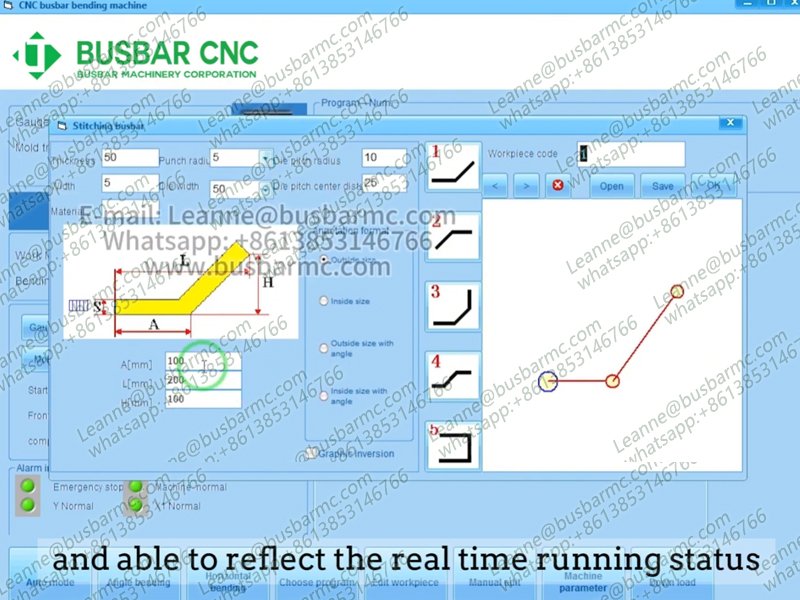

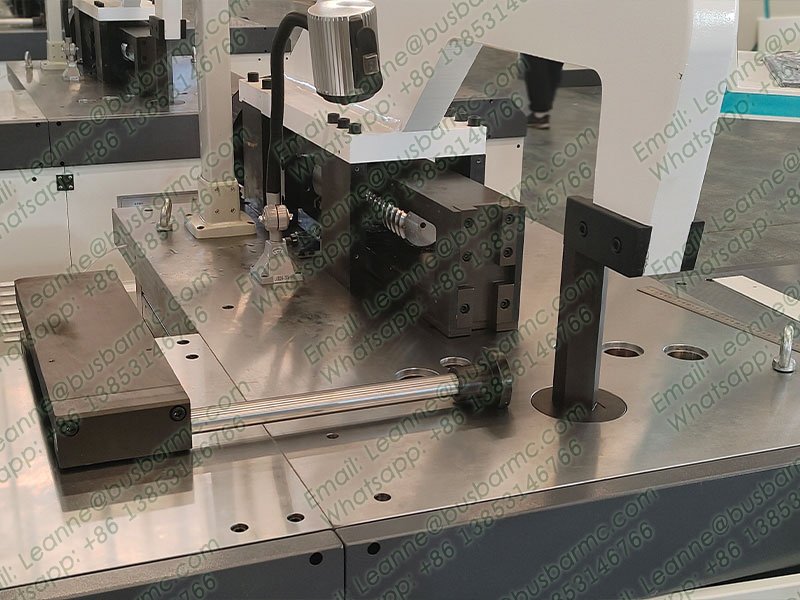

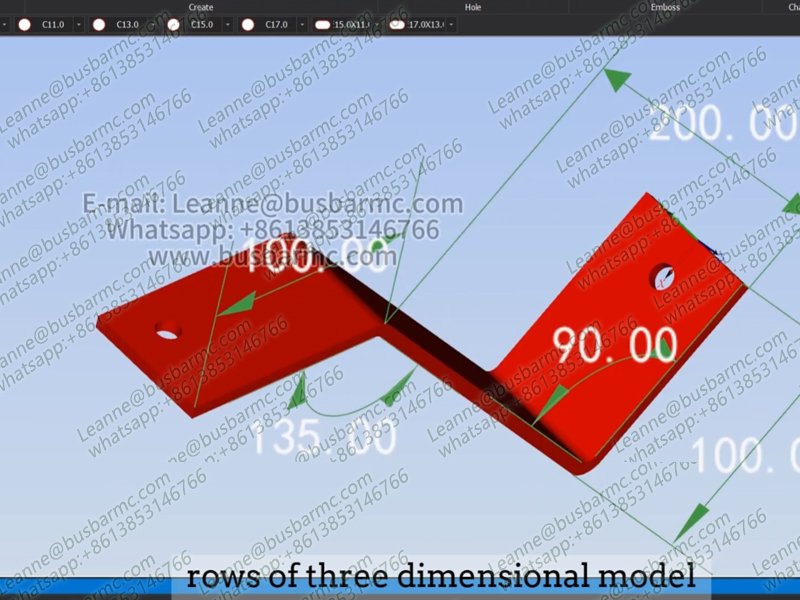

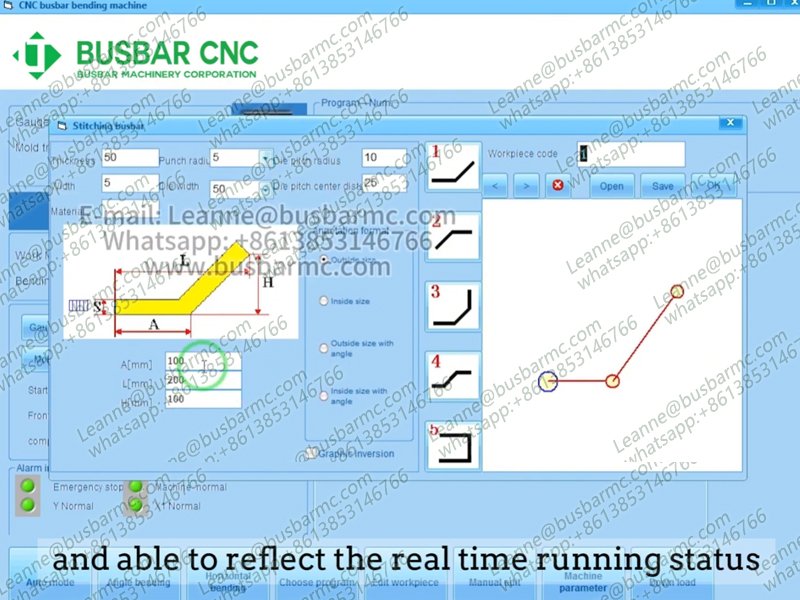

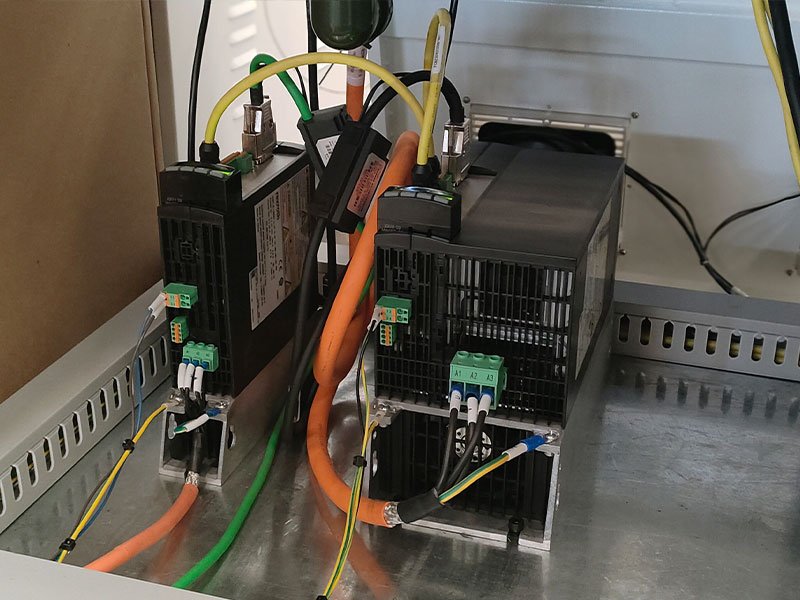

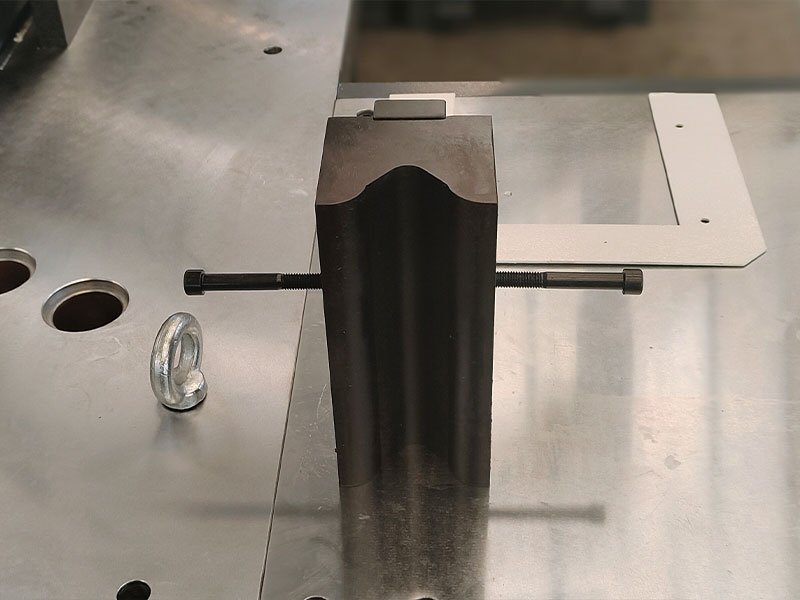

Discover the LT HQ400-B CNC Busbar Bending Machine—the ultimate solution for high-precision, automated bending of copper and aluminum busbars. Designed for industrial applications in switchgear, transformers, and power distribution systems, this machine combines advanced servo motor technology, CAD/CAM integration, and a robust closed-bending structure to deliver unparalleled accuracy and efficiency. Ultra-Precision Bending: Achieve bending accuracy of ±0.3° and material blocking accuracy of ±0.15 mm, ensuring consistent results for complex busbar shapes . Closed-Bending Structure: Enhanced mechanical strength and stability for long-term use without deformation . Full Servo Motor Drive: High output pressure, precise positioning, and energy-efficient operation . Smart CAD/CAM Software: Generate 3D models and machining codes instantly, with batch file support for streamlined production . Multi-Function Bending: Perform flat bends, vertical bends, U-bends, and more on busbars up to 15x200 mm . Applications: c- Low/High-Voltage Switchgear Transformer & Bus Duct Systems Renewable Energy & EV Power Distribution Industrial Power Control Panels Why Choose the LT HQ400-B? Automated Workflow: Reduce manual errors and increase productivity with CNC-controlled operations . Durability: Double linear guide rails and ball screw systems ensure smooth, noise-free performance . Global Compliance: Meets international standards for electrical fabrication (e.g., IEC, UL) CNCBusbarBending #LTHQ400B #BusbarMachine #ElectricalFabrication #CopperBending #AutomatedBending #PrecisionForming #CNCEquipment #IndustrialBending #BusbarTools

LT LT HQ400-B CNC Busbar Bending Machine Busbar Machine Videos:

Tags:

CNC busbar bending machine,automated busbar bending,electrical busbar fabrication,copper busbar bending machine,CNC busbar bending equipment,high-speed busbar processing,industrial busbar bending,CNC busbar bending system,automated busbar fabrication,busbar bending automation,CNC busbar bending solutions,busbar punching and bending machine,copper conductor bending,aluminum busbar bending,CNC busbar bending tools,busbar bending machine