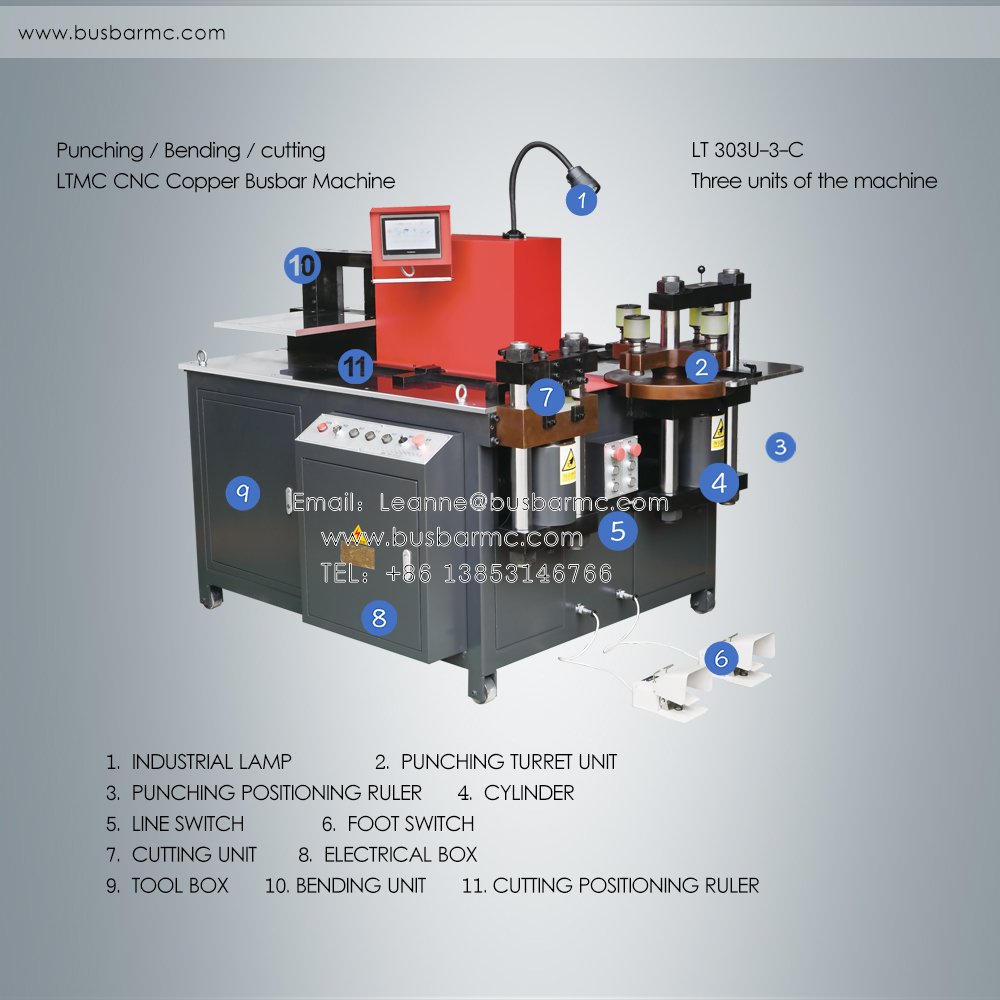

The 303U-3-C is a versatile 3-in-1 busbar processing machine that combines CNC punching, cutting, and bending functions. Ideal for processing copper busbars with a force of 300KN, it is widely used in switchgear and transformer manufacturing. This hydraulic busbar machine offers high precision and efficiency for electrical component production.

Product Description

copper busbar bending machine 303U-3-C

This series of busbar processing machine has three processing units: punching, shearing/cutting and bending. The three units can be used simultaneously or sequentially, the working stroke of each processing unit can be easily adjusted, which shortens the processing time and improves production efficiency. The main function is processing copper and aluminum busbar.

Technical Parameters

Item | Model |

303U-3-C | |

Nominal force (kn) | 300 |

Punching dia. range (mm) | ф4.3~ф25 |

Max.thickness (mm) | 12 |

Max.width (mm) | 150 |

Max.shearing thickness (mm) | 12 |

Max.shearing width (mm) | 150 |

Max.horizontal bending width (mm) | 150 |

Max.horizontal bending thickness (mm) | 12 |

Max.vertical bending size (mm) | 10×100 |

Power (kw) | 1×4KW |

Table size (mm) | 1650×1050 |

Outside dimension (mm) | 1720×1220×1220 |

Container size (mm) | 1800×1300×1430 |

Total weight (kg) | 1220KG |

Main Features

1. The cutting processing unit adopts vertical processing mode, flexible and convenient to operate. It adopts flat blade cutting, and the incision interface of workpiece is flat, no waste, burrs and droop.

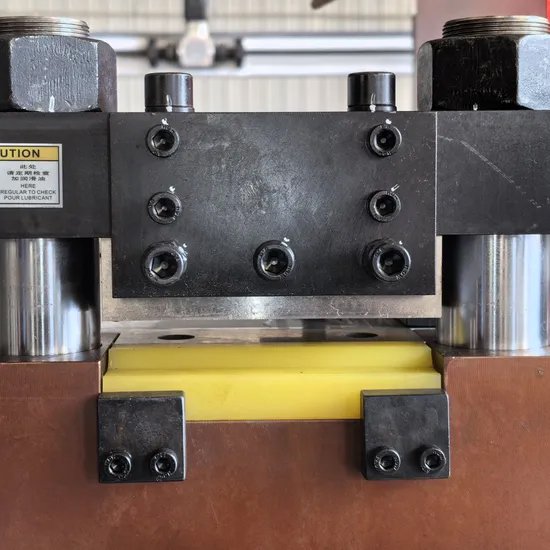

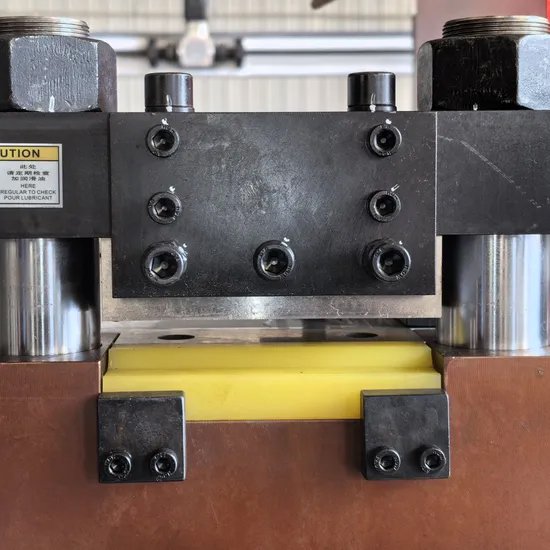

2. The punching unit uses a six-mode turnplate in tooth shape with good view, and no need to change the dies frequently, and the operation is simple and efficient.

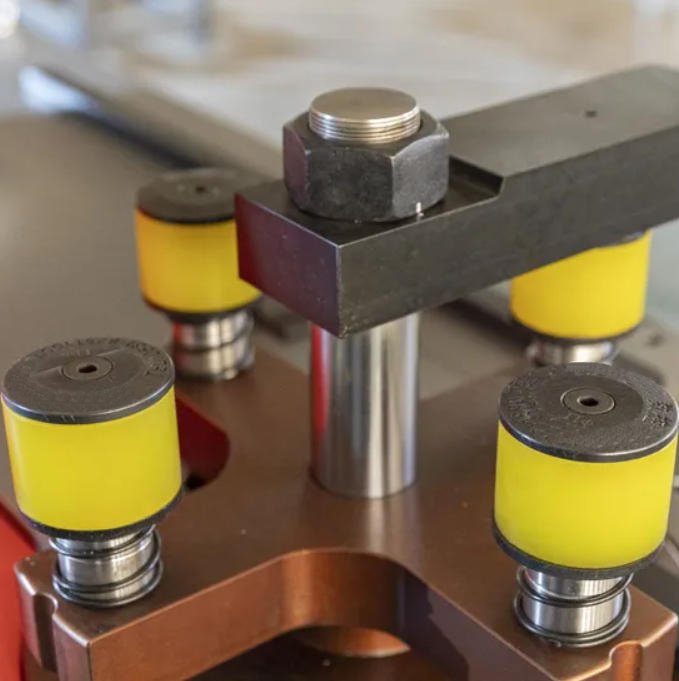

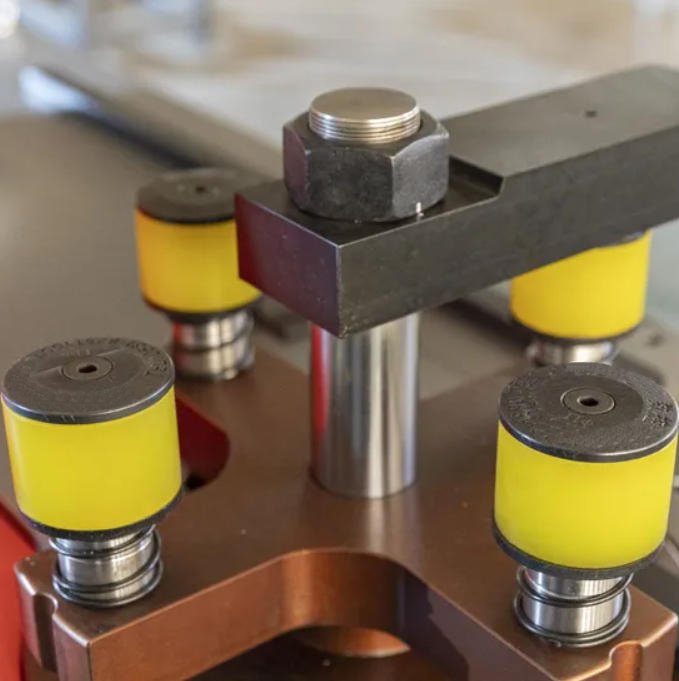

3. The bending unit adopts a horizontal bending. By changing molds, could be completed the processing of flat bending or vertical bending.

4. A variety of processing functions such as embossing, flattening, twisting, and crimping of cable ends can be achieved by changing the molds.

5. The machine has four casters, so it is easy to be moved everywhere needed.

6. Different molds or tools can be installed according to user requirements to complete special shape processing.

Product Details Dispaly

Processing

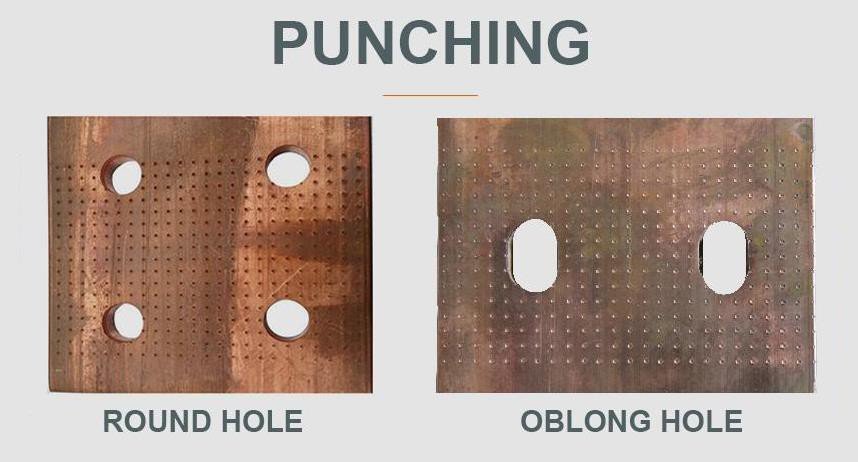

Punching samples

It can punch round hole and oblong hole with punching unit.

Cutting samples

The cutting unit adopts vertical cutting mode, flexible and convenient to operate. The interface of busbar is flat, no waste, no burr and droop.

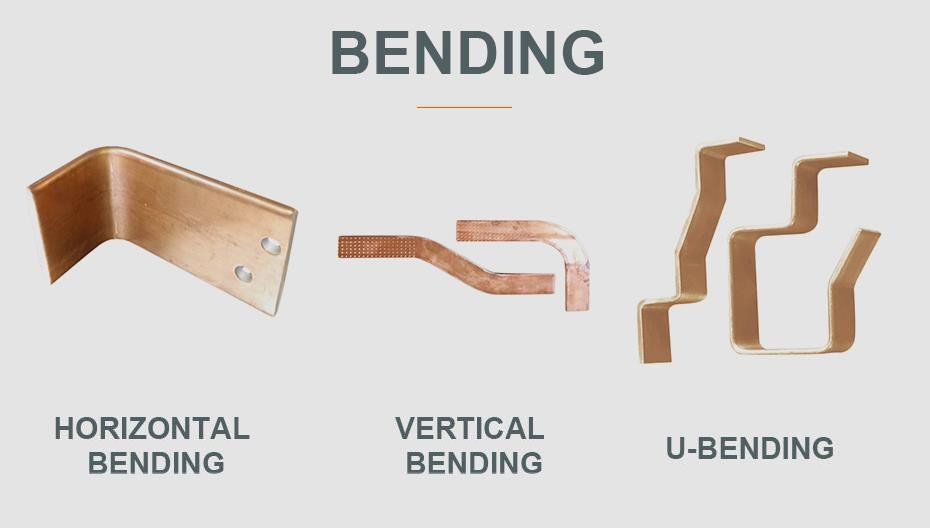

Bending samples

The bending unit adopts closed integral frame structure. It can bend flat bending, horizontal bending, vertical bending and U-bending.

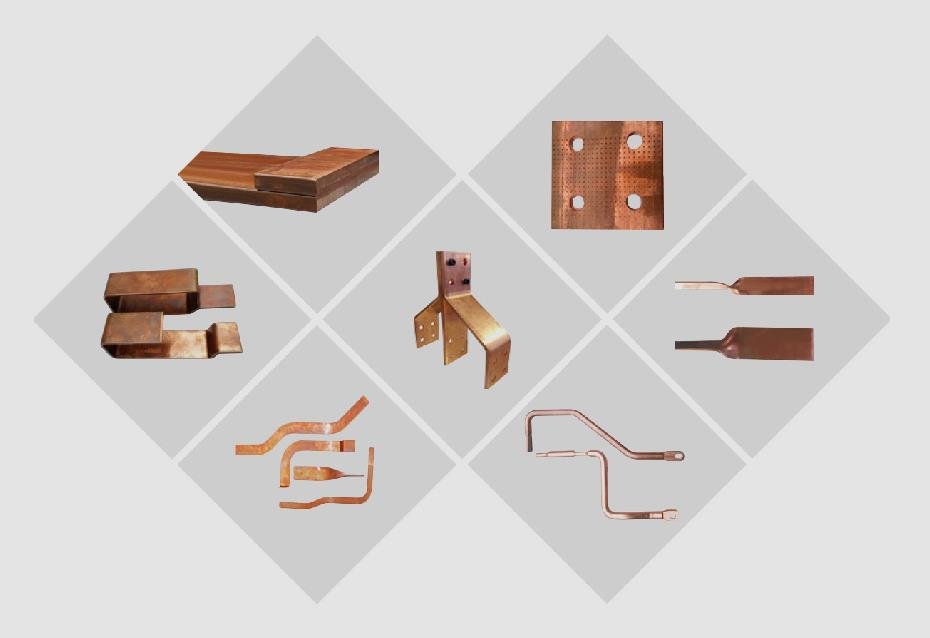

Other Processing Samples

Our Factory

Our Service

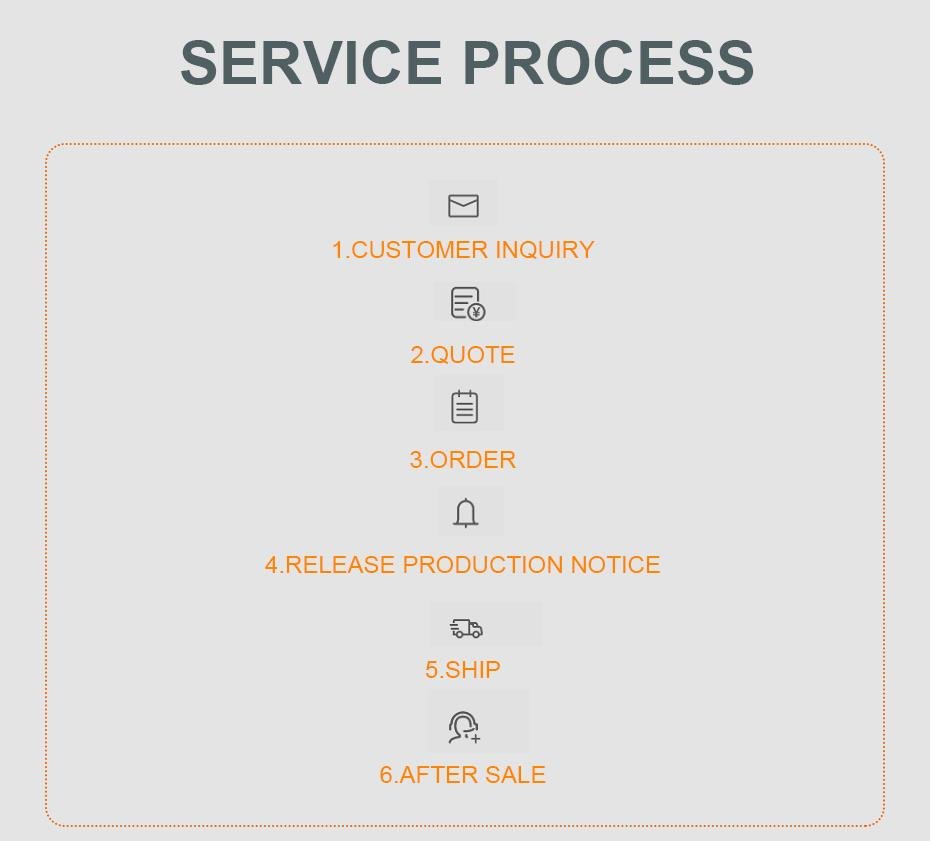

Customer inquiry - Quote - Order - Release production notice - Ship - After sale service

Our after-sales service engineers will also have return visit to you on a regular basis to listen to your valuable opinions and continuously improve product quality.

Package & Delivery

We use waterproof plastic film wrapped inside and wooden cases outside.

Our Clients

LTMC Company mainly deals in various types of busbar processing equipment.Its performance is excellent, and it is sold well in more than 100 countries around the world, including the United States, Britain, Germany, Russia, Canada, Belgium, Argentina, New Zealand, Czech Republic, Romania, Ireland, Peru, Chile, Australia, Hungary, Mexico, Slovenia, Malaysia, Brazil, Vietnam, Saudi Arabia, Pakistan, etc.

Hot Tags: three unit busbar processing machine with manual control 303U-3-C, China, suppliers, manufacturers, factory, price

LT Busbar Machine Videos:

303U-3-C 3 in 1 manual hydraulic busbar machine FAQ: This FAQ covers common questions regarding the 303U-3-C busbar processing machine, which integrates punching, shearing/cutting, and bending functions in a single unit.

Q1: What materials can the 303U-3-C process?

A1: The 303U-3-C machine is designed for processing copper and aluminum busbars of various specifications.

Q2: What are the maximum processing dimensions?

A2: The machine can handle a maximum thickness of 12mm and a maximum width of 150mm for punching, cutting, and bending operations.

Q3: How is the punching unit designed?

A3: The punching unit uses a six-mode turnplate in tooth shape, reducing the need for frequent die changes and ensuring efficient and precise punching.

Q4: What type of cutting does the machine use?

A4: The cutting unit adopts a vertical flat blade cutting mode, producing a smooth, burr-free interface without waste.

Q5: Can the machine perform different bending operations?

A5: Yes, the bending unit supports flat bending, horizontal bending, vertical bending, and U-bending by changing molds as needed.

Q6: Are there additional processing functions?

A6: By using different molds or tools, the machine can perform embossing, flattening, twisting, and crimping of cable ends.

Q7: Is the machine portable?

A7: The 303U-3-C is equipped with four casters, making it easy to move and operate on different job sites.

Q8: What power supply does the machine require?

A8: It operates on a 1×4KW power supply.

Q9: What are the table and machine dimensions?

A9: The table size is 1650×1050mm, the overall machine dimensions are 1720×1220×1220mm, and the total weight is 1220kg.

Q10: Who can use this machine?

A10: It is suitable for workshops, electrical manufacturing plants, switchgear production, busbar fabrication, and other industrial electrical equipment manufacturing applications.

Q11: What support and services are provided?

A11: LTMC provides complete after-sales service including installation guidance, operation training, regular follow-up, and continuous product improvement based on customer feedback.

303U-3-C 3 in 1 manual hydraulic busbar machine, copper busbar bending machine, busbar processing machine Hot Tags: cnc busbar machine, busbar cutting machine, busbar punching machine, copper busbar machine, aluminum busbar machine, hydraulic busbar machine, 3 in 1 busbar machine, portable busbar machine, flat bending machine, vertical bending machine, U-bending machine, busbar fabrication equipment, electrical workshop machine, switchgear manufacturing machine, industrial busbar machine, custom busbar processing, busbar die changing system, high efficiency busbar machine, busbar production tools, LTMC busbar machine, China busbar suppliers, busbar machine factory, CNC bending machine, metal busbar equipment, multi-function busbar machine