The 303U-3-C is a high-precision, triple-function CNC busbar processing machine engineered for integrated punching, cutting, and bending operations. It ensures efficient and accurate fabrication of copper or aluminum busbars used in switchgear, transformers, and power distribution systems. With robust construction and CNC-controlled positioning, the 303U-3-C improves productivity while maintaining consistent quality for medium to high-volume electrical component manufacturing.

Product Description

Main Features

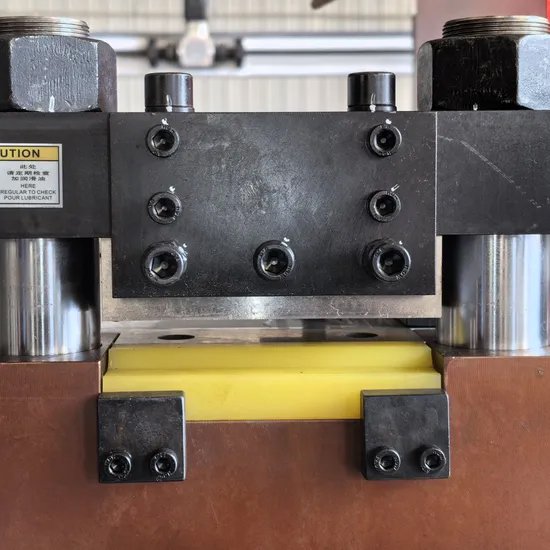

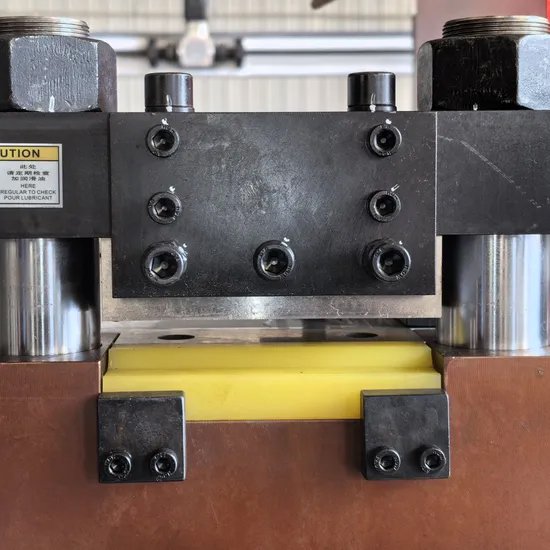

1. The shearing/cutting unit adopts double column shearing dies.

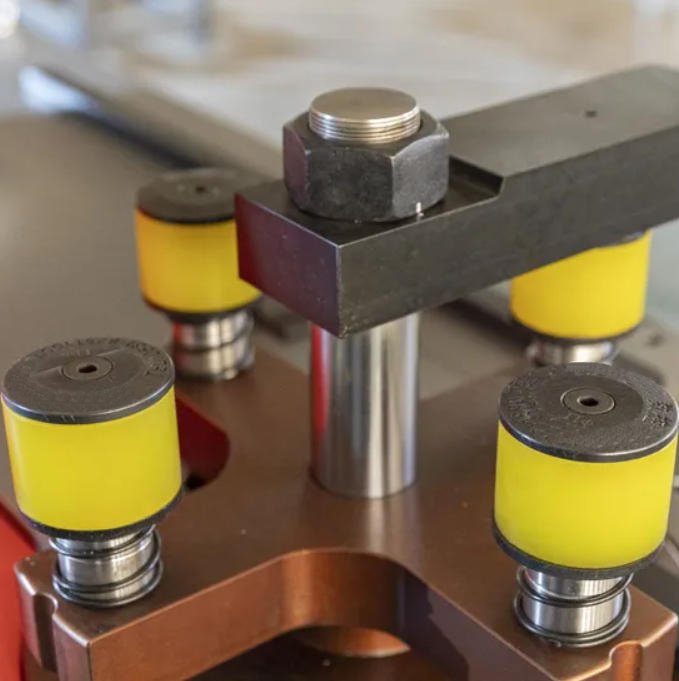

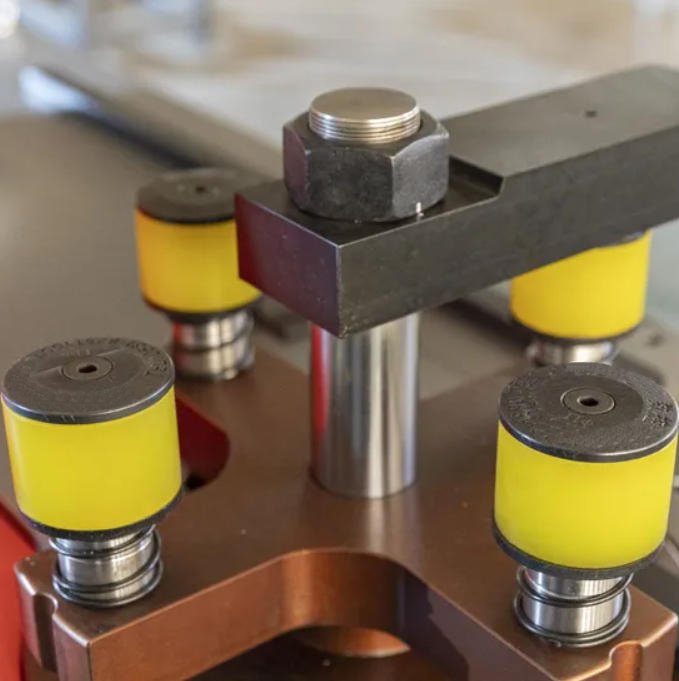

2. The punching unit is an integral six-mode turnplate, which ensure the upper and lower molds are absolutely in the center.

3. The bending unit adopts a closed bending structure, which makes it more uniform during processing horizontal bending and embossing, and improves the repeat positioning accuracy in mass production.

4. Different molds or tools can be installed according to user requirements to complete special shape processing.

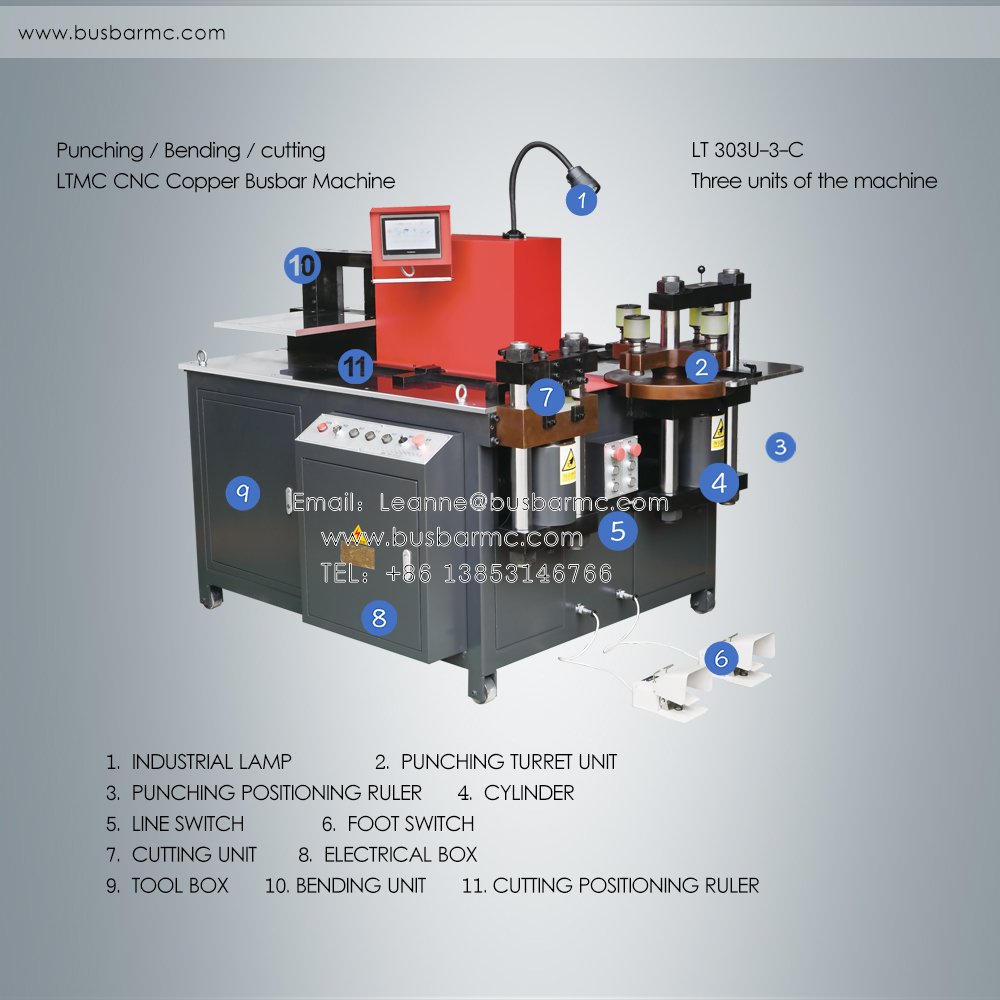

Product Details

1.CNC TOUCH SCREEN

2.INDUSTRIAL LAMP

3.PUNCHING TURRET UNIT

4.PUNCHING POSITIONING RULER

5.CYLINDER 6.LINE SWITCH

7.FOOT SWITCH 8.CUTTING UNIT

9.ELECTRICAL BOX

10.TOOL BOX

11.BENDING UNIT

12.CUTTING POSITIONING RULER

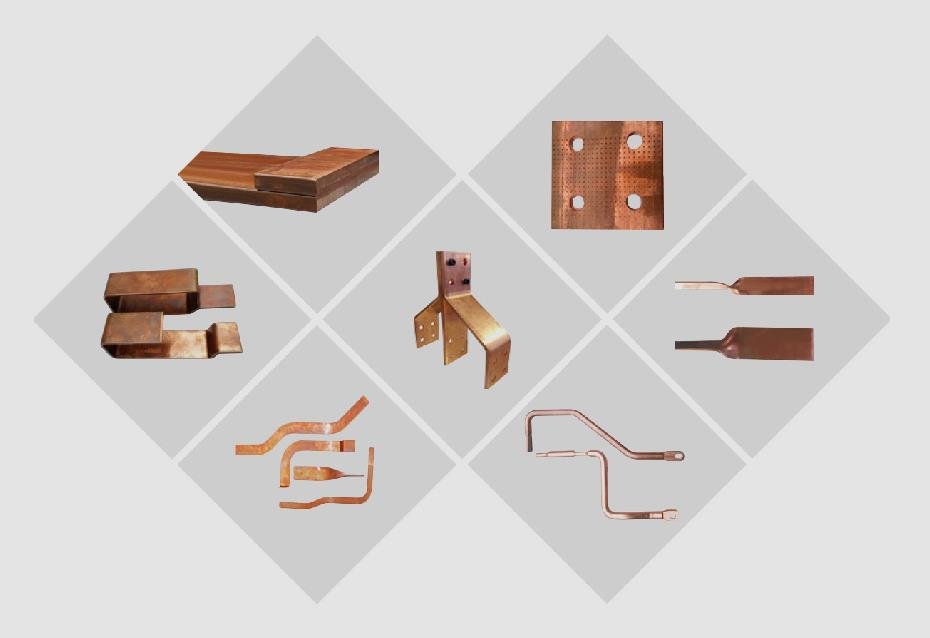

Processing Samples

LT-303U-3-C is a three functions busbar processing machine.

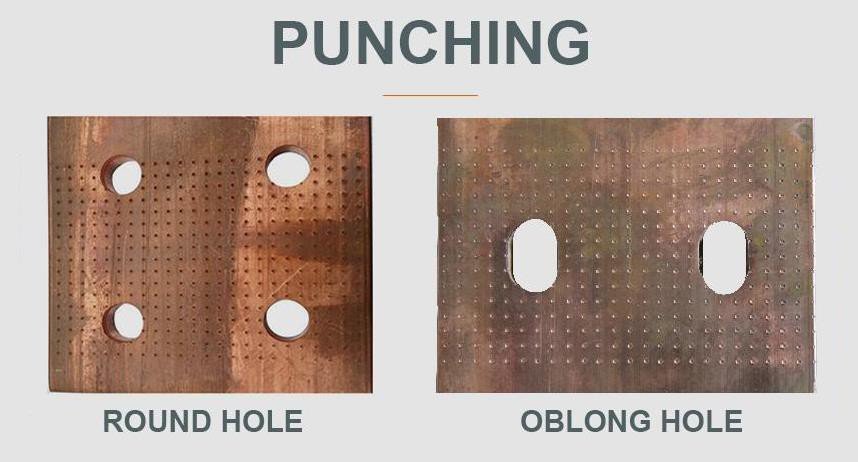

Function one: punch

For round hole punch, oblong hole punch.

Function two: cut

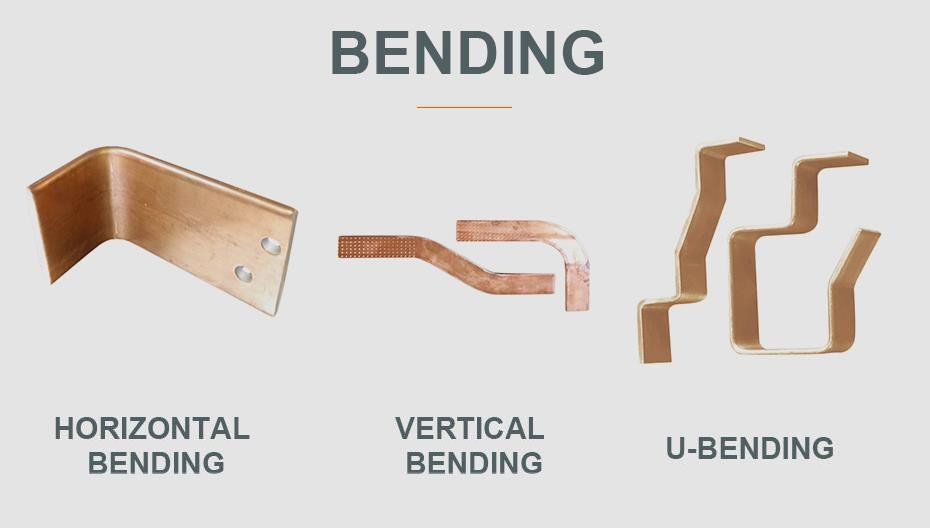

Function three: bend.

It can do vertical bending, flat bending, U-bending, and Z-bending by changing the molds.

Other functions

Our Factory

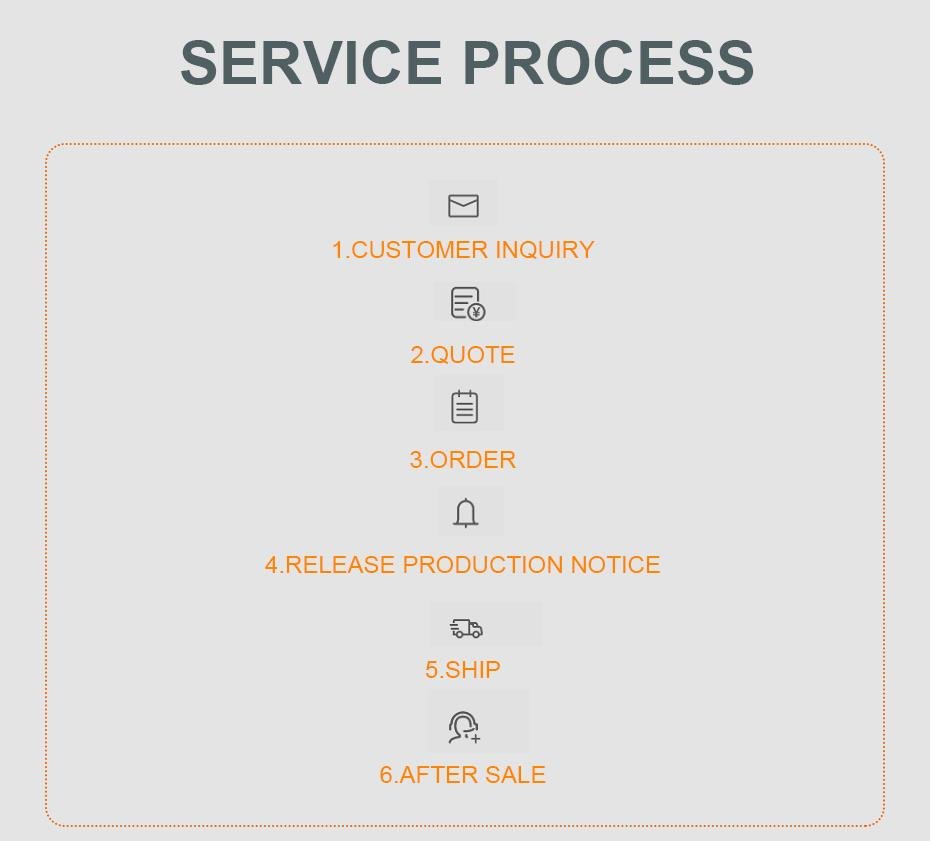

Our Service

Our after-sales service engineers will also have return visit to you on a regular basis to listen to your valuable opinions and continuously improve product quality.

Package & Delivery

We use waterproof plastic film wrapped inside and wooden cases outside.

Our Certifications

ISO9001:2000/CE

| Items | Model |

| LT-303U-3-C | |

| Nominal force (kn) | 300 |

Punching dia. range (mm) | ф4.3~ф25 |

Max. thickness (mm) | 12 |

Max. width (mm) | 160 |

| Max. shearing thickness (mm) | 12 |

| Max. shearing width (mm) | 160 |

| Max. horizontal bending width (mm) | 160 |

Max. Horizontal bendind thickness (mm) | 12 |

| Max. vertical bending size (mm) | 10×100 |

Power (kw) | 3×4KW |

| Bending precision (degree) | ±1° |

| Repeat bending precision (degree) | ±0.5° |

First table size (mm) | 1650×1050 |

Second table size (mm) | no |

| Outside dimension (mm) | 1720×1220×1240 |

| Container size(mm) | 1800×1300×1450 |

| Total weight(kg) | 1320KG |

LT Busbar Machine Videos:

303U-3-C 3 in 1 manual hydraulic busbar machine FAQ

Q1: What functions does the LT-303U-3-C busbar machine provide?

A: The LT-303U-3-C is a 3-in-1 multifunction busbar processing machine that can punch, cut, and bend copper and aluminum busbars. It supports round holes, oblong holes, shearing, vertical bending, flat bending, U-bending, and Z-bending through mold changes.

Q2: What is the punching capability of this machine?

A: The punching unit uses an integral six-mode turnplate to ensure upper and lower mold alignment. It can punch holes from Φ4.3 mm to Φ25 mm and is suitable for busbars up to 12 mm thick and 160 mm wide.

Q3: What are the shearing (cutting) specifications?

A: The cutting unit adopts double-column shearing dies for stable performance. It can shear copper or aluminum busbars up to 12 mm thick and 160 mm wide.

Q4: What type of bending structure does the machine use?

A: The machine uses a closed bending structure, which provides uniform force during horizontal bending and embossing, and improves repeat positioning accuracy, especially in mass production.

Q5: Can the machine be equipped with customized molds or tools?

A: Yes. Different molds or special tools can be customized based on user requirements to perform special-shaped processing.

Q6: What bending precision does the LT-303U-3-C achieve?

A: The machine offers a bending accuracy of ±1° and a repeat bending precision of ±0.5°.

Q7: What is the maximum vertical bending size?

A: The maximum vertical bending size is 10 × 100 mm.

Q8: What is the total power of this busbar machine?

A: The machine is equipped with 3 × 4 kW power units.

Q9: What components are included in the machine?

A: Main parts include: CNC touch screen, industrial lamp, punching turret unit, positioning ruler, cylinders, cutting unit, bending unit, electrical box, line switch, foot switch, and tool box.

Q10: What after-sales service is provided?

A: Our after-sales engineers will provide regular return visits, collect customer feedback, and continuously improve machine quality. Technical guidance and support are available.

Q11: How is the busbar machine packaged for delivery?

A: The machine is wrapped with waterproof plastic film inside and packed in wooden cases outside to ensure safe transportation.

Q12: Does the LT-303U-3-C have quality certifications?

A: Yes, the product is certified with ISO9001:2000 and CE standards.

Q13: What is the overall machine dimension and weight?

A: The machine size is 1720 × 1220 × 1240 mm, the container size is 1800 × 1300 × 1450 mm, and the total weight is 1320 kg.

Q14: Is this machine suitable for transformer or switchgear manufacturing?

A: Yes. With punching, cutting, and bending in one unit, it is commonly used in transformer plants, switchgear factories, and electrical panel manufacturing.

cnc busbar machine, copper busbar machine, aluminum busbar processing machine, busbar punching and shearing machine + Hot Tags

cnc busbar machine, copper busbar machine, aluminum busbar processing machine, busbar punching and shearing machine, cnc busbar fabrication machine, hydraulic busbar processing machine, copper bar punching machine, copper bar bending machine, cnc copper bar cutting machine, power distribution busbar equipment, switchgear busbar processing machine, industrial busbar fabrication equipment, automatic busbar production machine, heavy duty busbar workstation, copper and aluminum busbar forming machine, precision cnc busbar system, electrical panel busbar fabrication machine, programmable busbar punching machine, copper busbar manufacturing equipment, cnc copper bar handling system, busbar forming and cutting equipment, high-precision busbar processing unit, electrical cabinet copper bar machine, multi-function busbar fabrication line, copper busbar machining equipment, cnc copper busbar forming tool, industrial electrical busbar machine, servo-controlled busbar punching system, copper bar processing center, automatic copper aluminum busbar line, copper bar hole punching machine, electric power distribution busbar machinery, busbar punching cutting bending combo machine, cnc copper bar workstation, advanced busbar production technology, automated copper busbar equipment