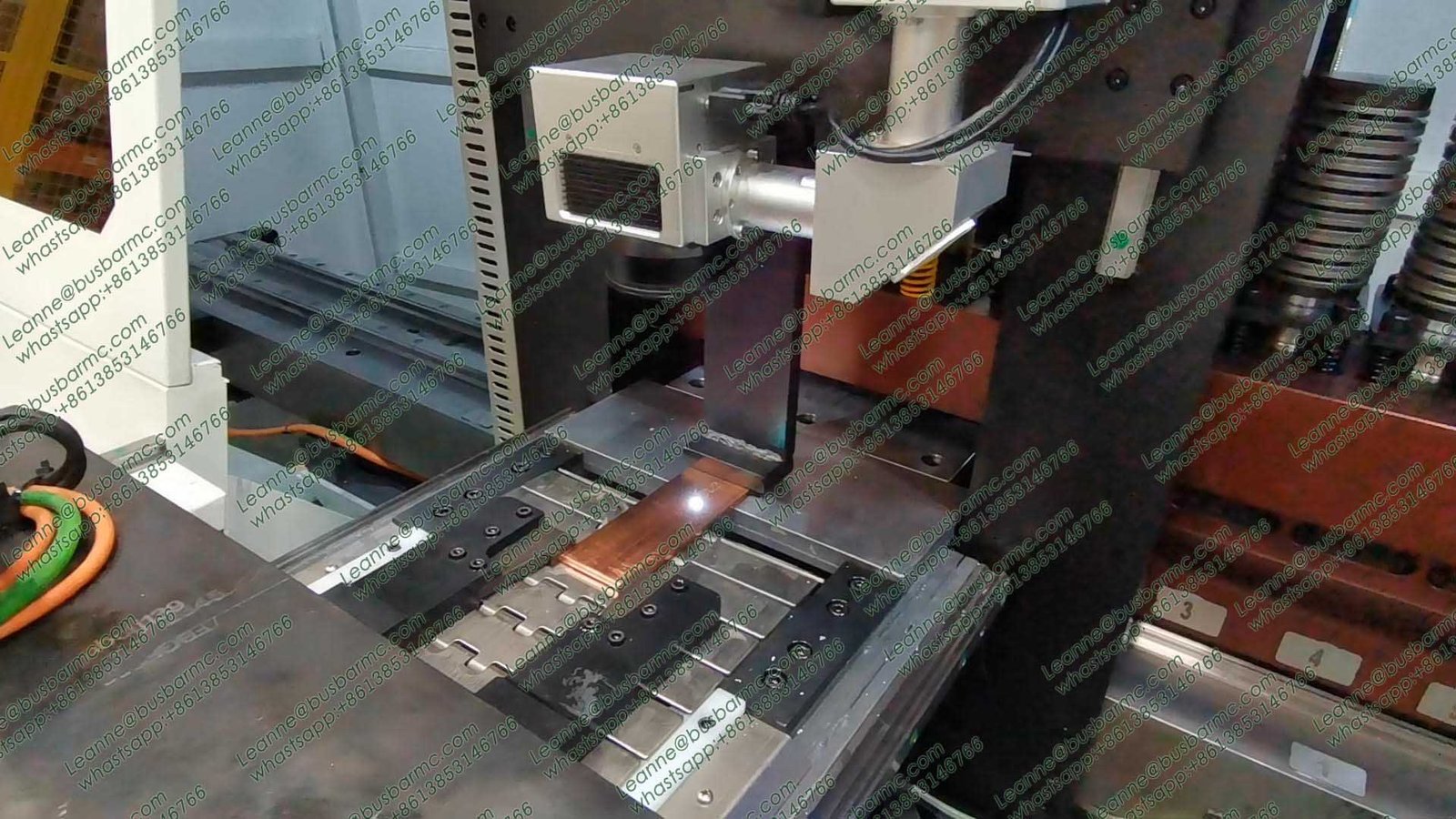

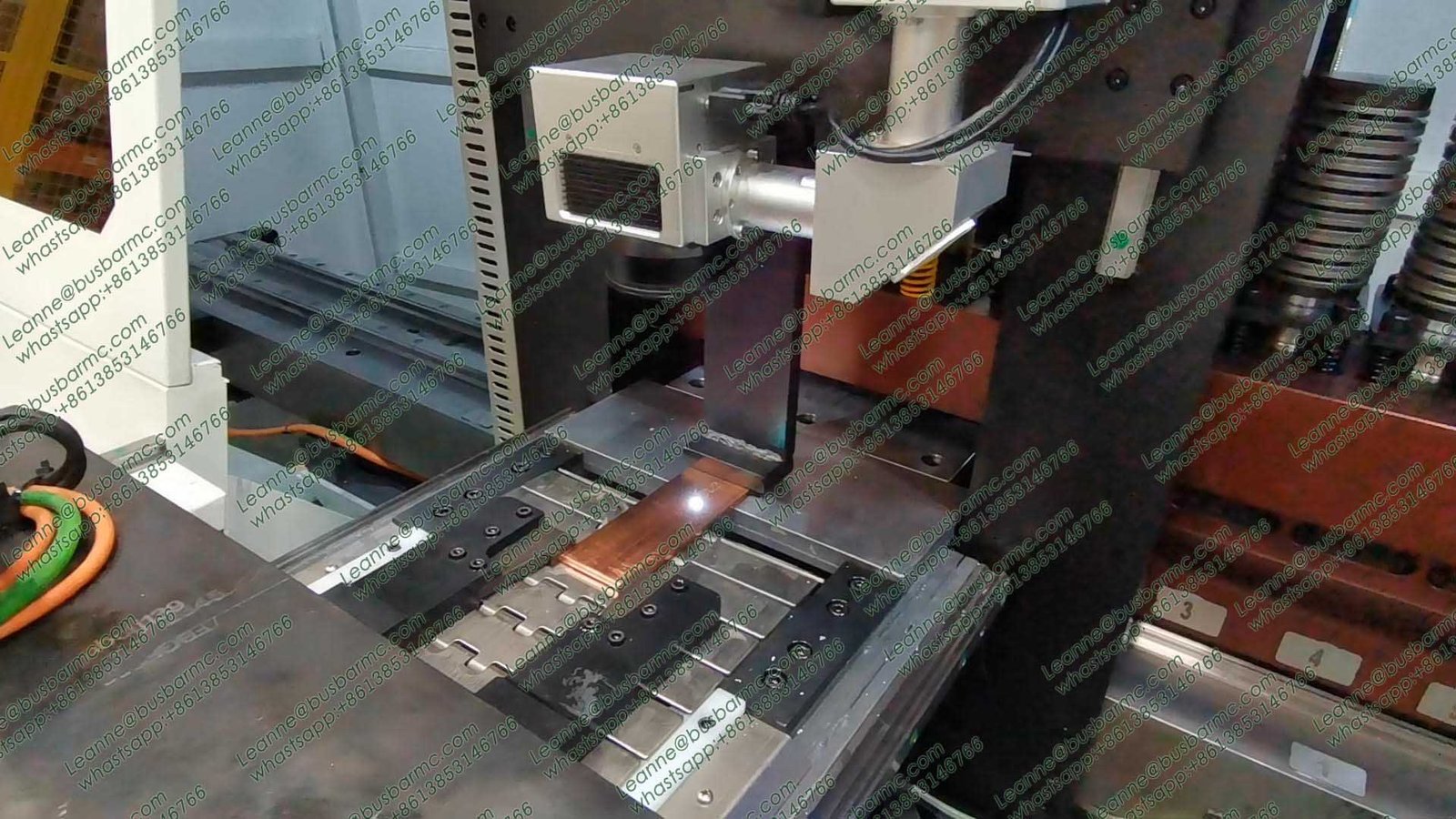

The HQ600-S-7/8P CNC Busbar Punching Shearing Machine delivers precision cutting, punching, chamfering, and embossing for copper/aluminum busbars in high/low voltage systems. Featuring patented hydraulic technology, automated clamp switching, and optional 7/8-punch + 1-shear dies, it ensures waste-free processing with 0.2mm accuracy. Includes BMC control system and ductile iron mold base for industrial durability.

Product : CNC Copper Busbar Punching Machine

Serial:HQ600-SP

Main Function:

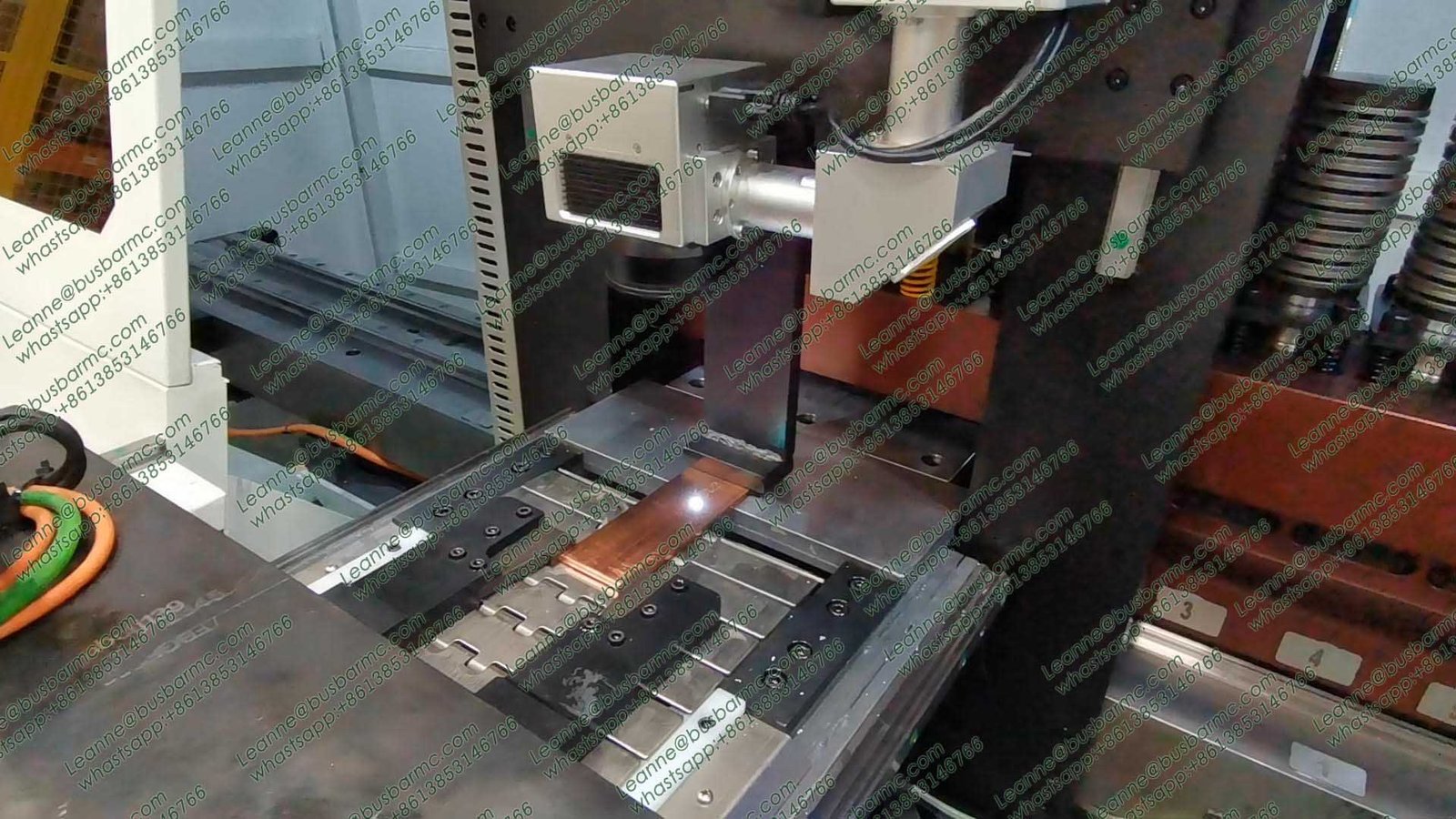

Cut,punch,chamfer,emboss (all kinds of round,square,special holes and slot type ) the copper, aluminum busbar etc.

Main Feature:

This machine specializes in processing copper and aluminum busbars for high and low voltage systems, offering

high efficiency, low energy consumption, precision, ease of use, and a modern design.

This machine features unique processing principles, a patented hydraulic cylinder system, and a daily capacity

of several tons, making it the top choice for busbar processing.

It allows single clamping for long busbars, automating punching and shearing without manual intervention through

automatic clamp switching. Optional 7/8-punch and 1-shear inline die sets; embossing available.

Cutting dies is a single pole type hedge Scissor, no waste after shearing.

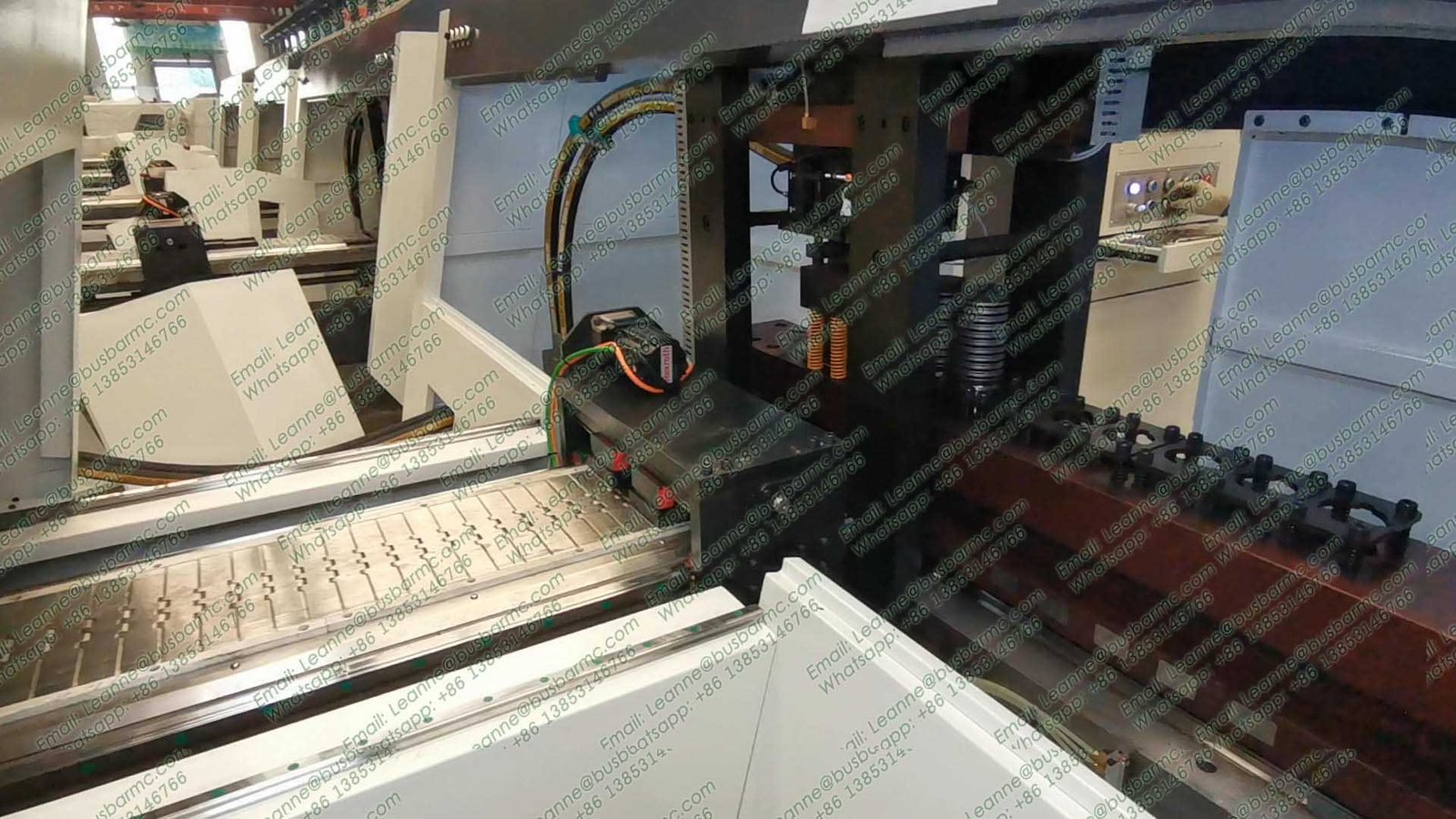

The machine comprises a feeding table, mould base, conveying system, servo control unit, and assistant design

system, delivering stable and reliable performance.

Featuring a user-friendly interface and the self-developed BMC busbar processing design system, it provides

real-time monitoring of program operations.

The mould base, made of ductile iron, offers excellent wear resistance, ensuring long-term Concentricity of

punching molds.

| Parameter | HQ400-S-7P/8P | HQ600-S-7P/8P |

|---|---|---|

| Nominal Pressure | 400KN | 600KN |

| Maximum Processing Size | 12×160mm | 15×200mm |

| Punching Range | Φ4.3-25mm | Φ4.3-35mm |

| Maximum Number of Molds | 8punch 1shear 1emboss | 7punch+1emboss 1shear |

| X-Axis Express | 2000mm | 2000mm |

| X-Axis Positioning Speed | 60m/min | 75m/min |

| Y-Axis Express Travel | 860mm | 960mm |

| Y-Axis Positioning Speed | 35m/min | 35m/min |

| Z-Axis Express Travel | 2000mm | 310mm |

| Z-Axis Positioning Speed | 35m/min | 35m/min |

| Punching Accuracy | ±0.2mm | ±0.2mm |

| Positioning Accuracy | 0.10/500mm | 0.10/500mm |

| Punching Speed | 100 times/min | 120-150 times/min |

| Number of Control Axes | 6 Axis | 6 Axis |

| Machine Dimensions (L×W×H) | 10500×2750×1700mm | 10500×2900×1800mm |

| Component | Option 1 | Option 2 |

|---|---|---|

| Main Motor | Juli | ABB |

| Hydraulic Pump | Taiwan Hydromax | American Albert |

| Solenoid Valve | Taiwan Litand | German Rexroth |

| Guides/Screws | HIWIN / TBI/PMI | HIWIN / TBI/PMI |

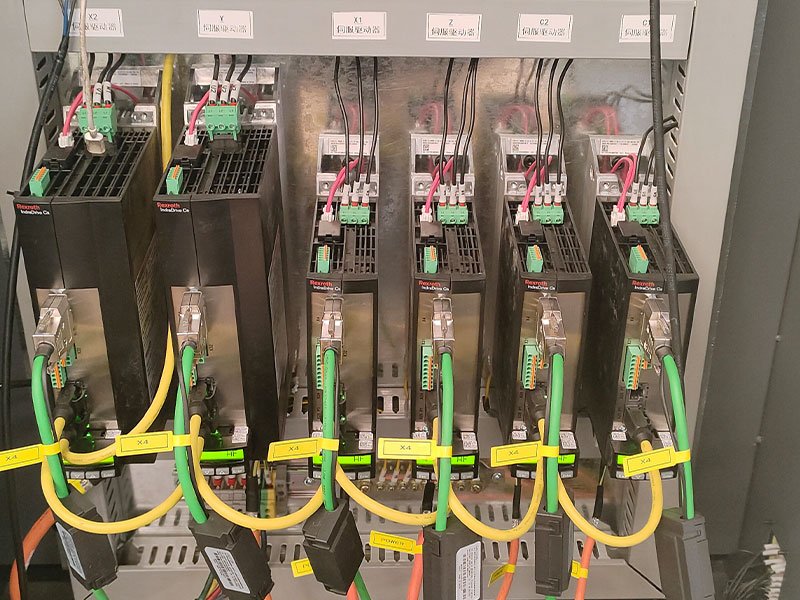

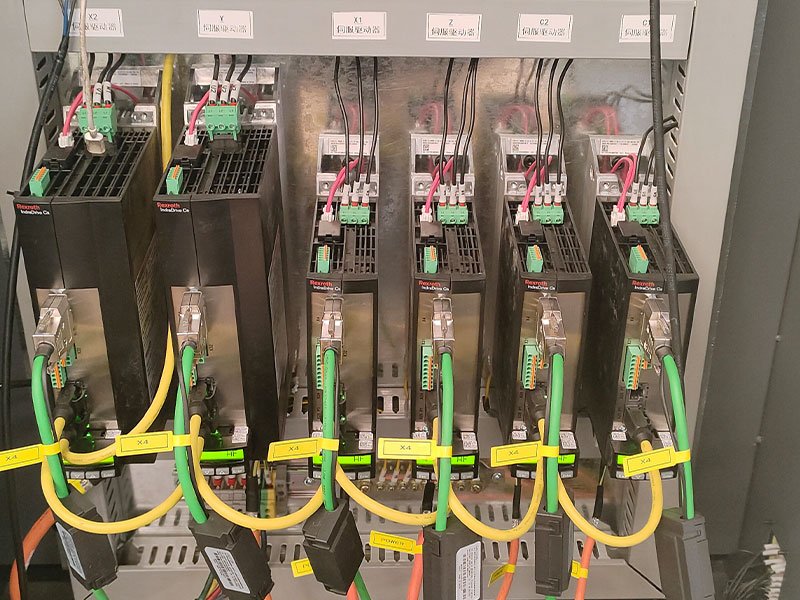

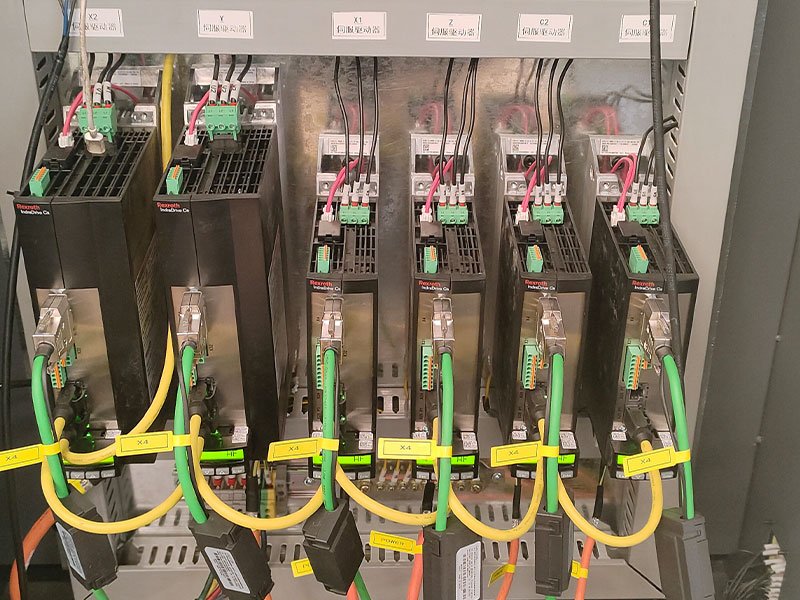

| Servo System | Exton | German Rexroth |

| Industrial Computer | Taiwan PanelMaster (Touch Screen) | Beijing Qiyang |

Random Accessories:

8 sets of punching dies, 1 shear blade, 1 set of maintenance tools, and manuals with certificates included.

Video:

HQ600-S-7P CNC Busbar Punching & Shearing Machine — FAQ

Q1: What materials can the HQ600-S-7P process?

A: The machine is designed to process copper and aluminum busbars, suitable for applications such as switchgear, distribution panels, control cabinets and busbar fabrication.

Q2: What are the machine's maximum processing dimensions?

A: Maximum plate size is 6000 × 200 × 15 mm. Maximum processing thickness is 15 mm and maximum processing width is 200 mm.

Q3: How many punching, shearing and embossing dies does it have?

A: The HQ600-S-7P uses a straight-column single-row die bank with 7 punching dies, 1 shearing die and 1 embossing die arranged in the same row.

Q4: What hydraulic and motor specifications does it use?

A: The hydraulic system supplies up to 600 kN of pressure and is driven by a Swiss ABB motor, as stated in the product details.

Q5: What control and servo systems are used?

A: The machine is equipped with a German Beckhoff control system and German Rexroth servo motors/servers for 6-axis control, providing closed-loop control and high positioning accuracy.

Q6: What accuracy and axis travel can I expect?

A: X- and Y-axis accuracy is listed as 0.10 mm per 500 mm. X-axis maximum travel is 2000 mm, Y-axis maximum travel is 960 mm, and Z-axis maximum travel is 310 mm.

Q7: What is the punching and shearing speed?

A: The X-axis maximum positioning speed is 75 m/min in operational conditions (150 m/min under no-load condition is noted in the specification). Punching/shearing working speed is described as up to 40 m/min in the feature text.

Q8: How many control axes and what are the machine dimensions?

A: The machine has 6 control axes. Overall machine dimensions are 10,500 × 2,750 × 1,800 mm and the stated weight is 6,700 kg.

Q9: Does the machine support CAD/CAM integration?

A: Yes — the product description indicates CNC control plus CAD/CAM system compatibility to improve programming and production efficiency.

Q10: How can I obtain pricing and demonstrations?

A: For the latest pricing, availability, lead time and machine videos/demonstrations, please contact the sales team or authorized distributor. The product text invites contacting sales for the latest busbar punching and shearing machine prices.

Busbar processing machine, CNC busbar machine, copper busbar punching machine, hydraulic busbar machine + Hot Tags</strong>

busbar processing machine, CNC busbar machine, copper busbar processing machine, copper busbar punching machine, copper busbar bending machine, CNC busbar punching machine, busbar fabrication equipment, busbar manufacturing machine, hydraulic busbar machine, busbar cutting machine, automatic busbar production line, aluminum busbar processing machine, busbar punching and shearing machine, CNC electrical busbar machine, power distribution busbar equipment, high-precision busbar machining, industrial busbar equipment, electrical panel busbar machine, switchgear busbar fabrication machine, heavy-duty busbar workstation, electrical copper bar machine, busbar forming machine, programmable busbar machine, HVAC busbar fabrication tool, energy distribution busbar machine, substation busbar processing equipment, electric cabinet copper busbar machine