Copper bar Aluminum bar Bend, U-bend , Stand up,CNC Busbar Bending Copper CNC Busbar Bending.Nominal Pressure - 400KNGauge Length: 1200mm;Horizontal bend maximum size: 15 x 200mm;Vertical bend maximum siza: 12 x 120mm;Gauge accuracy: 0.15 ;Bending accuracy: 0.3 ;Machine size: 3500 x 1450 x 1850 mm;Weight of machine : 3100kg;

Product: CNC Copper Busbar Bending Machine

Model: HQ400-1200B / HQ400-2000B

Main Function: Copper and Aluminum Busbar Flat Bending, U-Bending, Vertical (Stand-Up) Bending

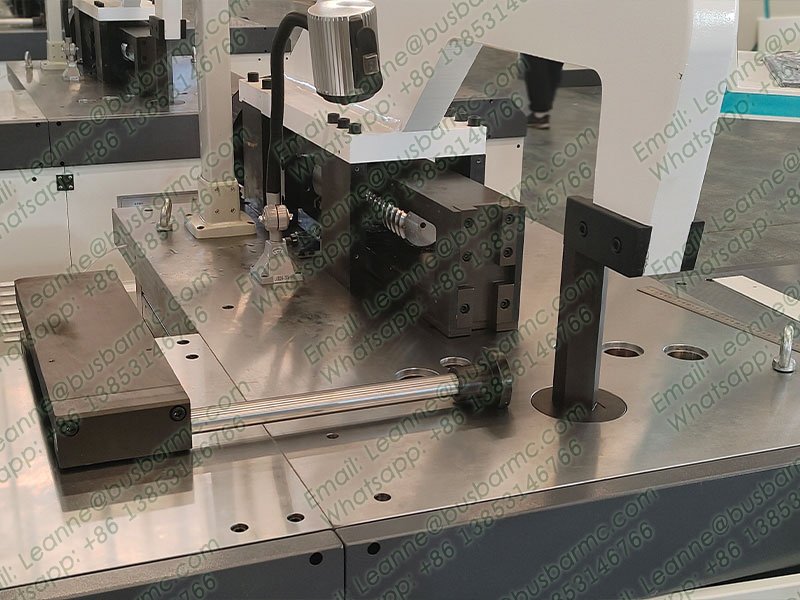

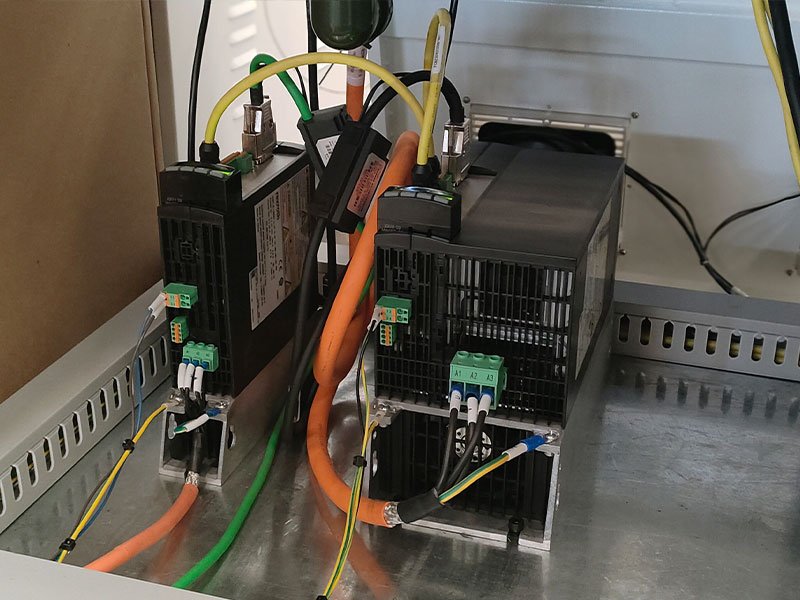

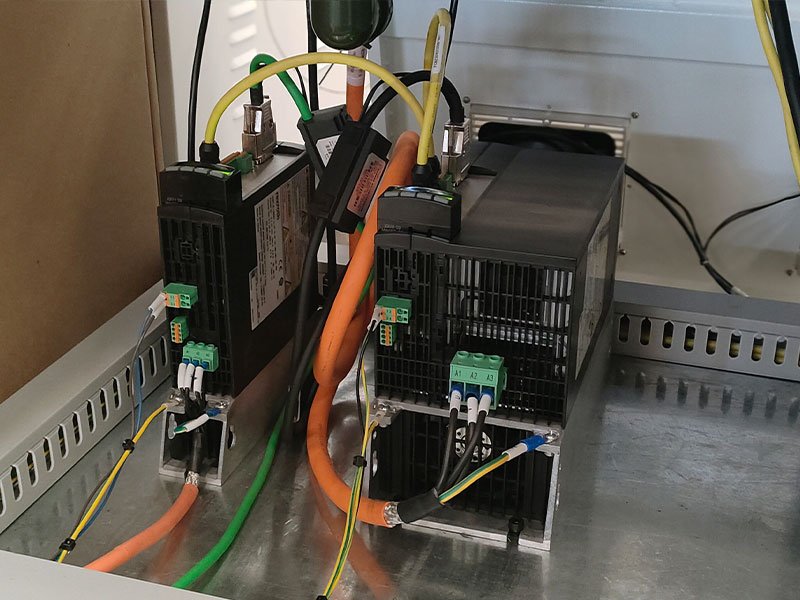

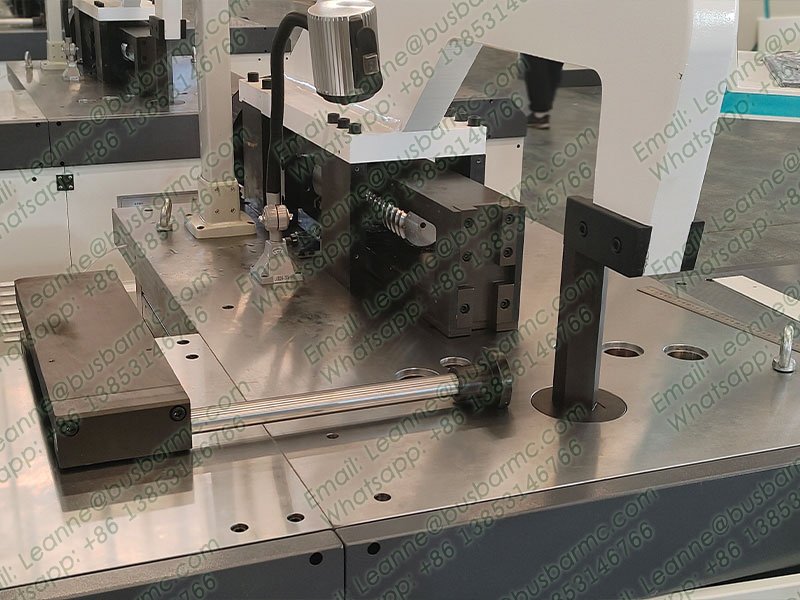

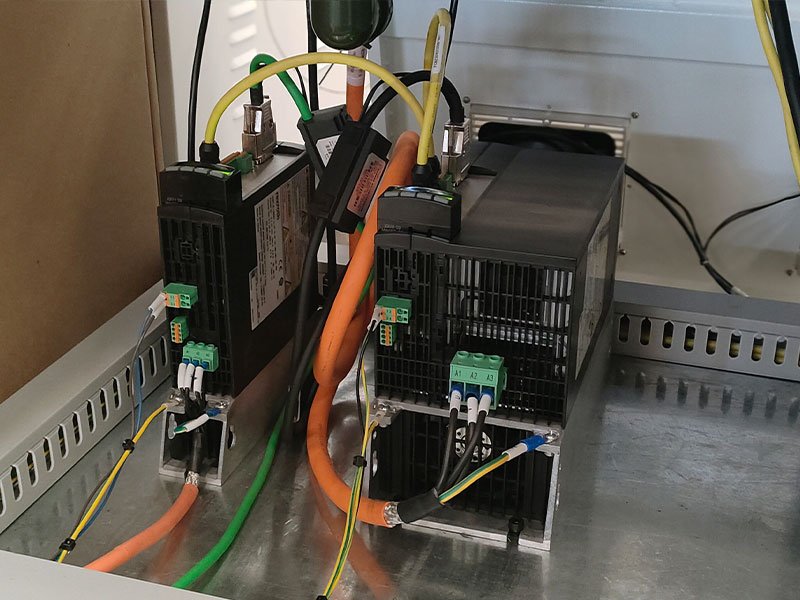

1. Fully servo motor drive system with stable transmission, high output pressure and accurate positioning.

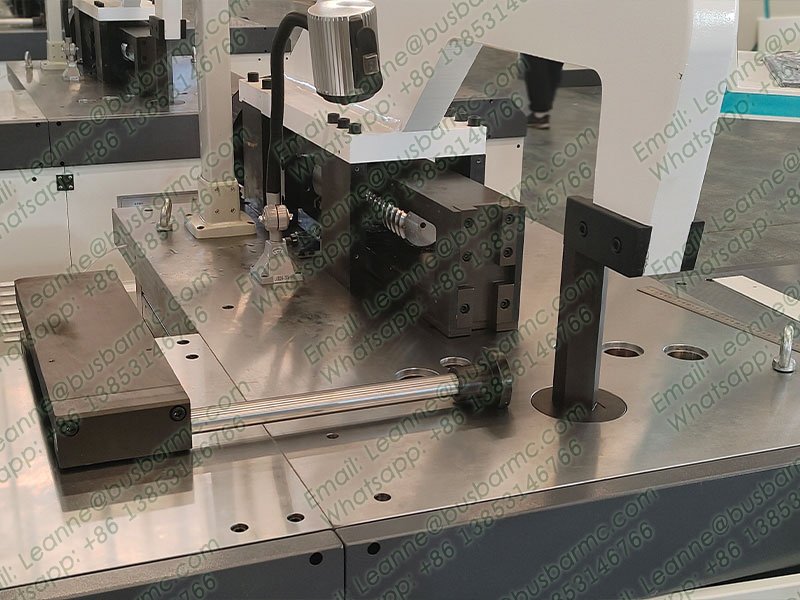

2. Closed bending structure with balanced force, high mechanical strength, and long-term stability without deformation.

3. Double linear guide rails and ball screw ensure smooth, low-noise operation.

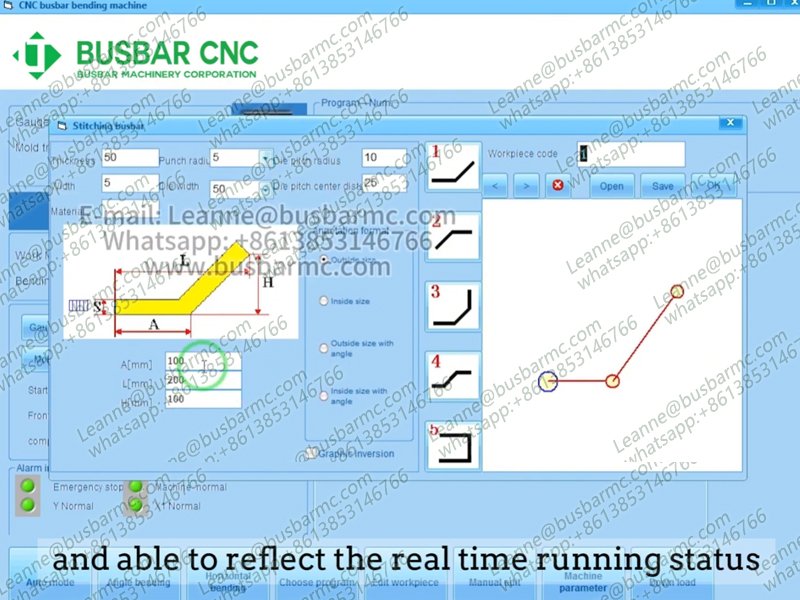

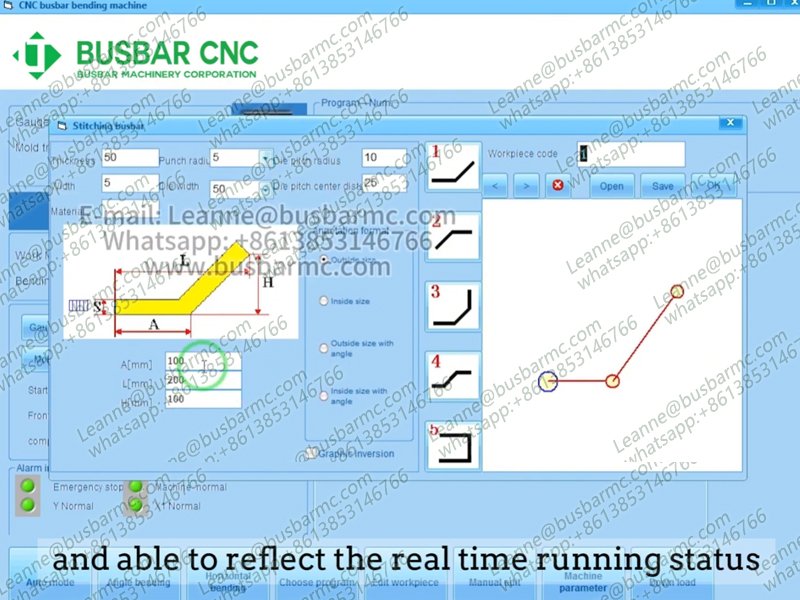

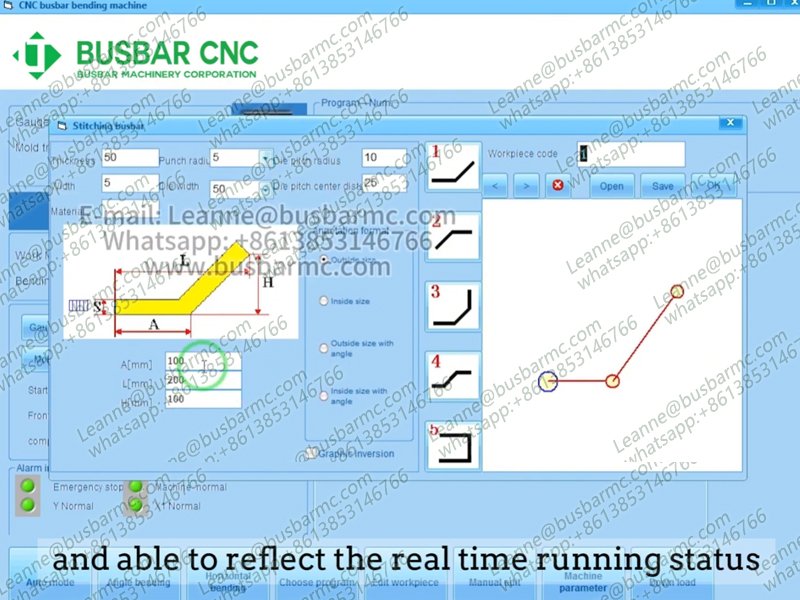

4. Industrial computer + PLC control system for precise bending angle and material positioning.

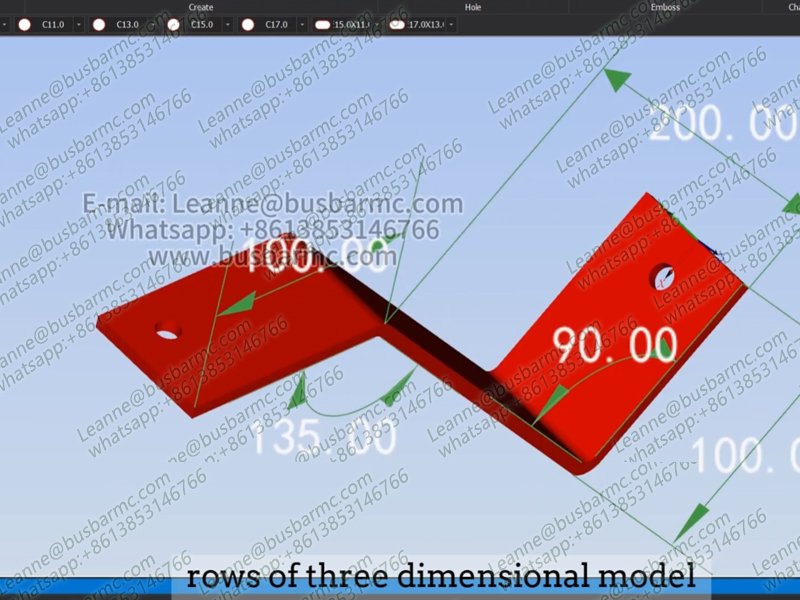

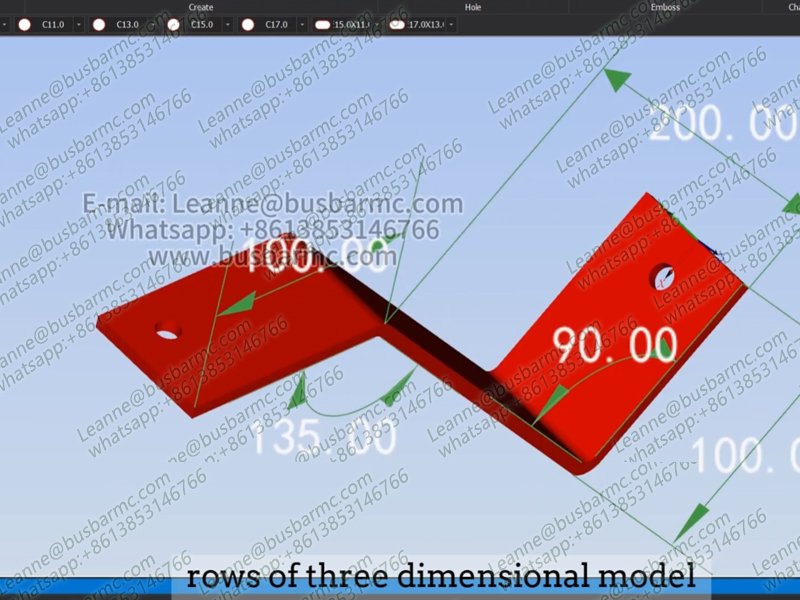

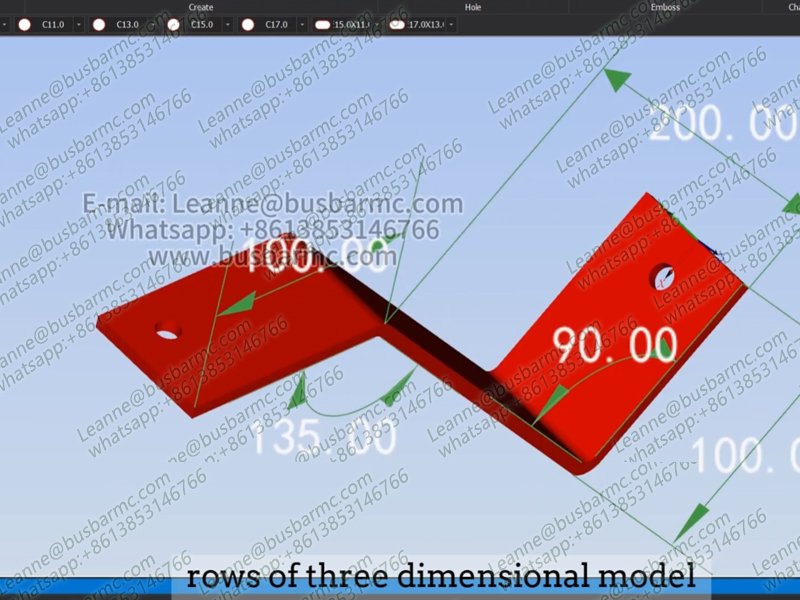

5. Equipped with self-developed CAD/CAM programming software for easy operation and fast code generation.

6. Supports flat bending, vertical bending, and pipe bending with corresponding molds.

7. Easy mold installation and replacement, stable blocking and bending accuracy.

8. Supports batch import of bending files and visual generation of machining programs.

Nominal Pressure: 400KN

Gauge Length: 1200mm

Max Horizontal Bending Size: 15 × 200mm

Max Vertical Bending Size: 12 × 120mm

Gauge Accuracy: ±0.15mm

Bending Accuracy: ±0.3°

Machine Size: 3500 × 1450 × 1850mm

Machine Weight: 3100kg

1. What materials can this machine process?

It is suitable for copper and aluminum busbars.

2. What bending types are supported?

Flat bending, U-bending, and vertical bending.

3. What control system does it use?

Industrial computer and PLC control with servo motor drive.

4. Is CAD/CAM software included?

Yes, self-developed CAD/CAM software is supported for programming.

5. Can it work with CNC punching and shearing machines?

Yes, it supports integration with HQ600-SP CNC punching and shearing machines.

6. Is batch processing supported?

Yes, batch import and visual program generation are supported.

7. Can molds be customized?

Yes, multiple molds can be customized according to busbar size.

8. Is the machine easy to operate?

Yes, the CNC operating system is designed for simple and convenient operation.