Multi-functional Punching & Shearing Machine Long service life of high qu

HQ-600-B Double heads busbar trunking system copper bending machine

Main Function:

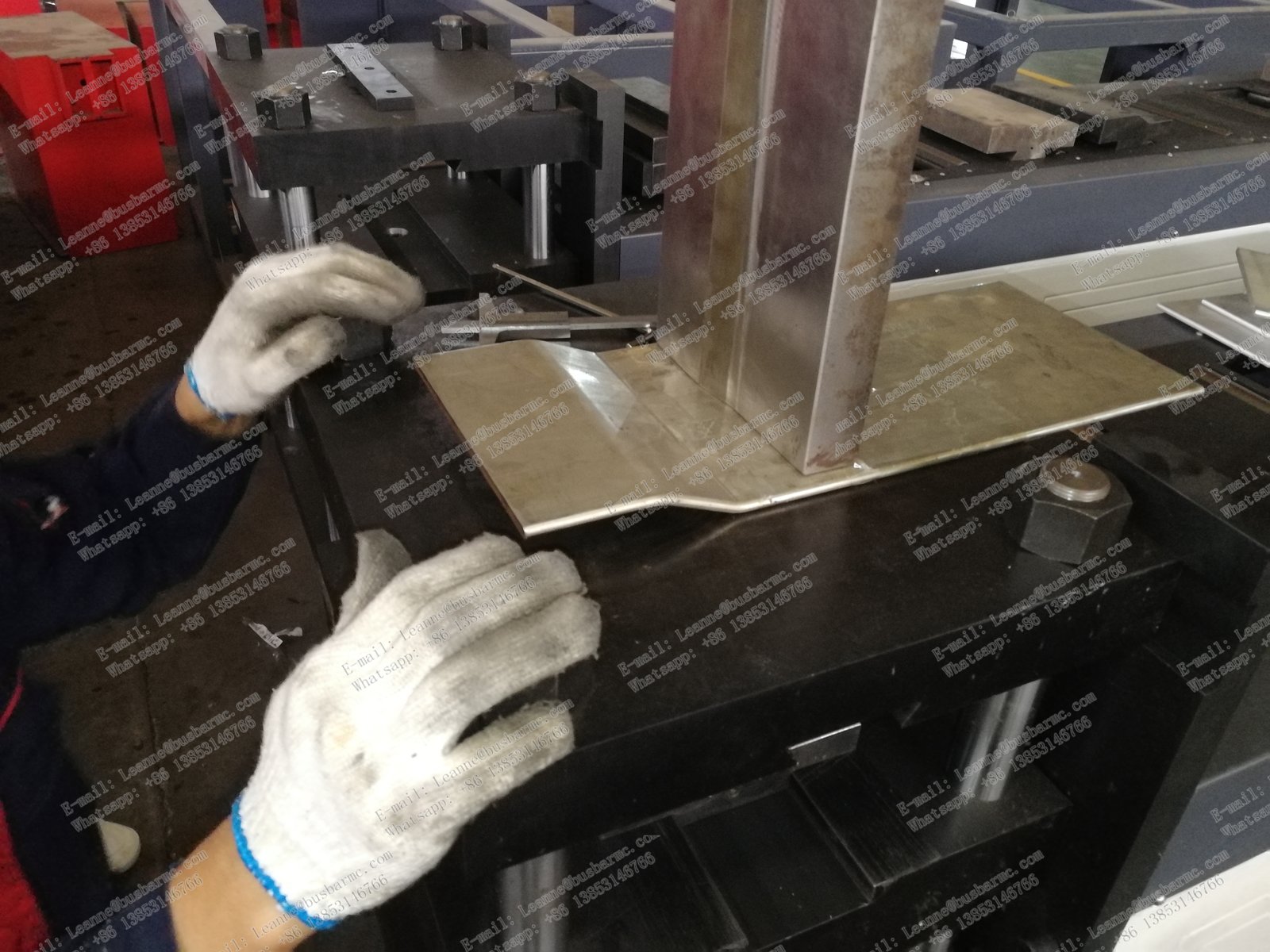

Double heads bus dust bending press a new type of processing equipment developed by our company,the main functions is bending the two ends of connection busbar of the line of the bus dust,and bending double bends once for each end of the bus dust.No need to change the direction of one bus dust,with the advantages of high processing speed,less steps,high accuracy,saving time and labor etc.

Main Features:

1.This machine mainly for bending the two ends of connection busbar of the line of the bus dust.

2.The two ends of the machine adopts hydraulic working mode, which has the advantages of high pressure, stable performance and so on.

3.The double bends of the two ends of the busbar are formed once, fast processing speed, high efficiency.

4.Large tonnage hydraulic cylinder with large flow gear pump, to ensure the running speed of the equipment.

5.Major components are well-known brands, to ensure the stability of the device.

Nominal pressure

600KN

Machining range

3 * 30-6 * 200mm

Overall size

3600 * 1500 * 1000mm

high efficiency

HQ-600-B Double Heads Busbar Trunking System Copper Bending Machine FAQ

1. What is the main function of the HQ-600-B double heads busbar bending machine?

This machine is designed to bend both ends of the connection busbar used in busbar trunking systems. It can complete double bends on each end in one operation without rotating the busbar, improving speed and efficiency.

2. How does the double-head design improve productivity?

The double-head structure allows simultaneous processing of both ends of the busbar, reducing handling steps, saving time, and greatly increasing bending accuracy and processing speed.

3. What is the working mode of this machine?

The machine uses hydraulic working mode on both ends, offering high pressure, stable performance, and reliable bending operations.

4. What are the advantages of hydraulic bending?

Hydraulic pressure ensures consistent force, high accuracy, faster bending, and stable operation, suitable for large batches of busbar trunking connectors.

5. Can the machine complete double bends in a single cycle?

Yes. Both ends of the busbar can be formed with double bends at once, which significantly improves the processing efficiency.

6. What ensures the bending speed of the equipment?

The machine is equipped with a large-tonnage hydraulic cylinder and a high-flow gear pump to ensure fast and smooth operation.

7. Are the machine components reliable?

Yes. The major components are from well-known brands, ensuring machine stability, durability, and long-term performance.

8. What is the machining range of the HQ-600-B model?

The machine can process busbars within the range of 3 × 30 mm to 6 × 200 mm.

9. What is the nominal pressure of this machine?

The nominal pressure is 600 kN, providing strong bending force for copper and aluminum busbars.

10. What is the overall machine size?

The overall size of the machine is 3600 × 1500 × 1000 mm.

11. What types of industries use this machine?

It is widely used in busbar trunking system manufacturing, electrical distribution workshops, switchgear production, and power engineering installation companies.

12. Does this machine help reduce labor intensity?

Yes. Since the busbar does not need to be rotated and both ends are bent in one process, the overall workload, time consumption, and handling effort are significantly reduced.

Hot Tags: HQ-600-B double heads busbar bending machine, busbar trunking system bending machine, copper busbar bending press, hydraulic busbar bender, high efficiency busbar machine, double-end busbar bender, industrial busbar processing equipment, CNC busbar bending machine, copper and aluminum busbar bender, automatic busbar bending system, electrical busbar fabrication machine, busbar connector bending machine, large tonnage busbar press, high precision busbar bender, double-head hydraulic bending machine, fast busbar bending equipment, power distribution busbar bender, trunking system copper bending machine, heavy-duty busbar machine, professional busbar processing machine